Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

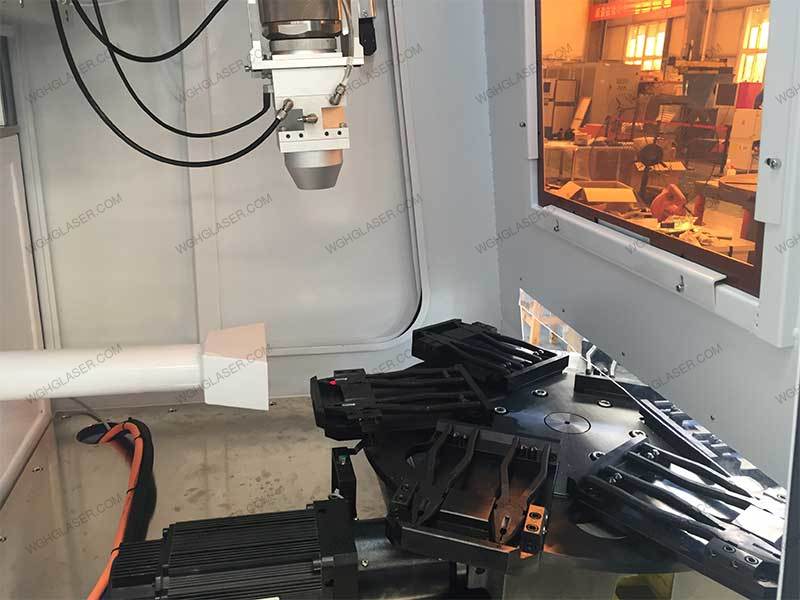

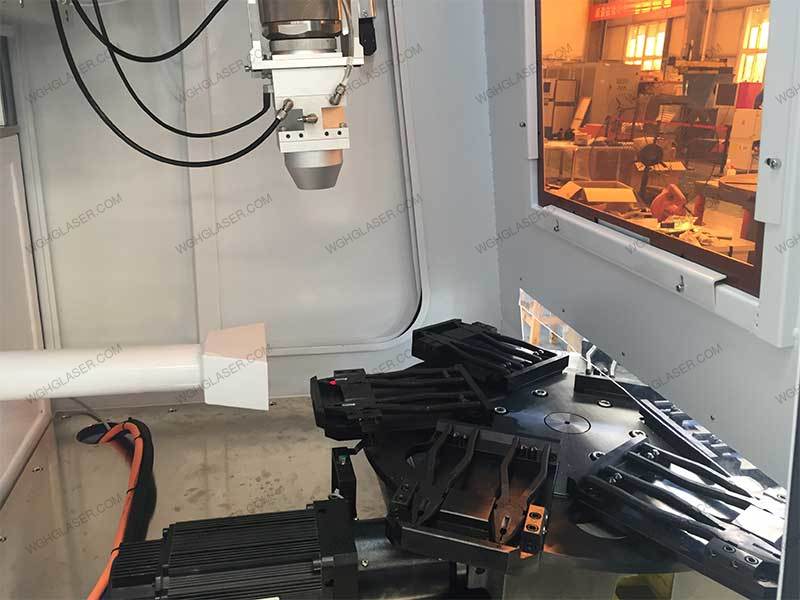

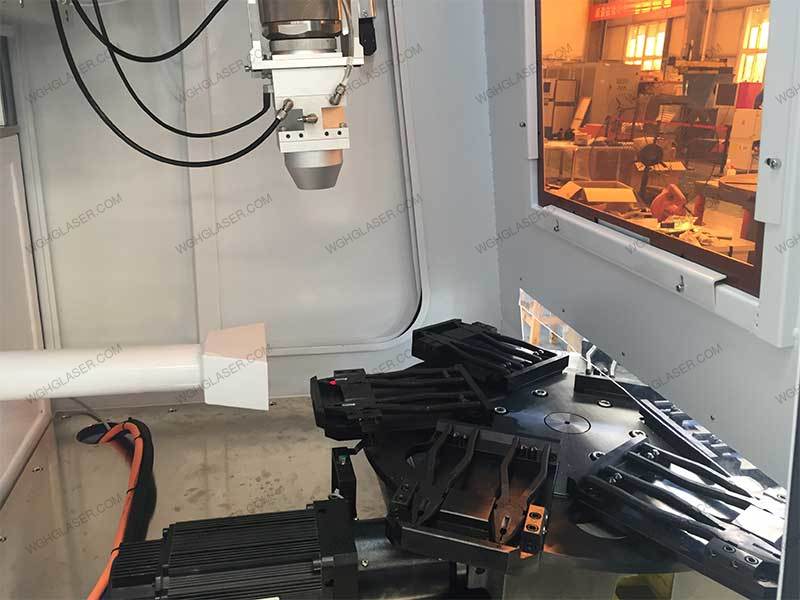

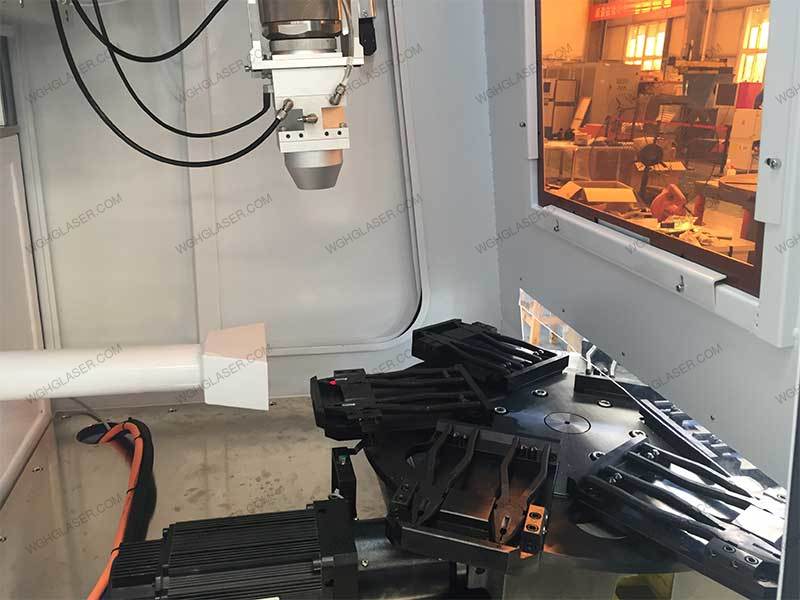

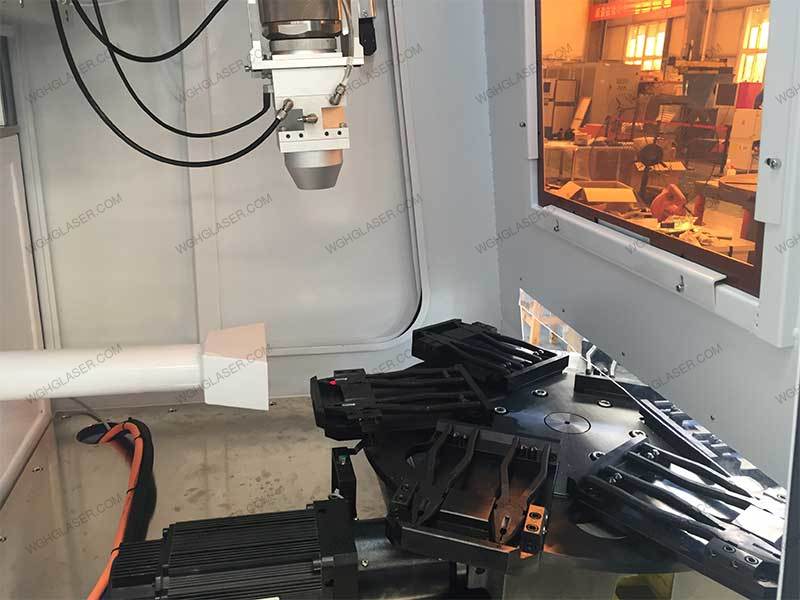

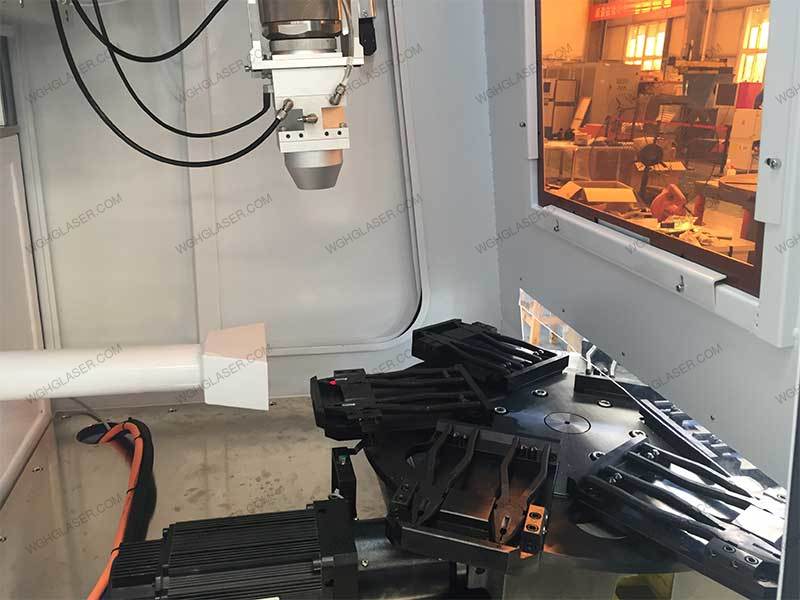

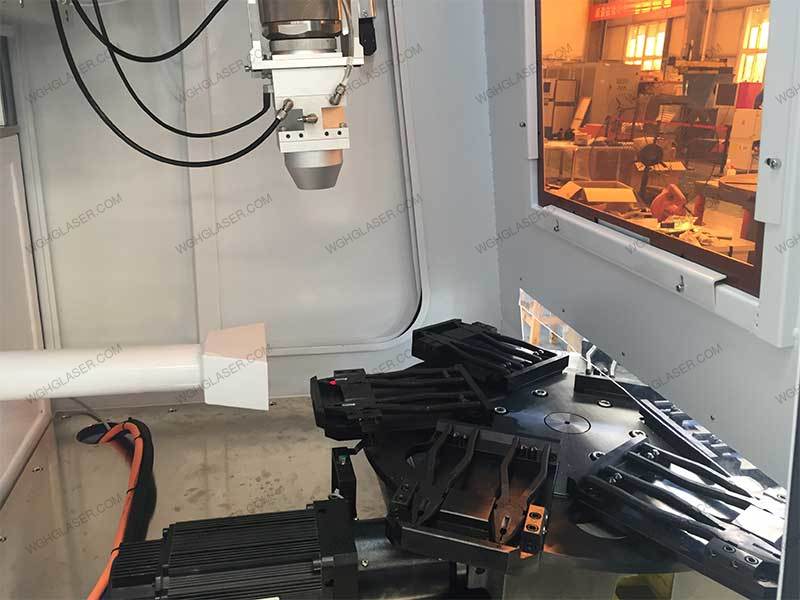

JCK Tool Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: hardware tools.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Characteristics of laser quenching process: the hardening layer has a controllable depth, small heat effect, high hardness and good wear resistance and is not easy to deformation and decarburization to improve service life of the product, without the post process treatment required.

Characteristics of laser cladding technology: laser cladding has high bonding strength, controllable hardness and small deformation, which makes "good steel needs to be used in the blade" for improving the performance of new products and re-manufacturing and repairing of waste products, so as to improve product life and save cost.

Advantages Introduction:

Compact structure and small volume

Easy to install and operate

Low energy consumption, energy saving and environmental protection

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for Vise

Laser quenching for Vise

Laser quenching for pliers

Laser quenching forSurgical forceps

Laser quenching

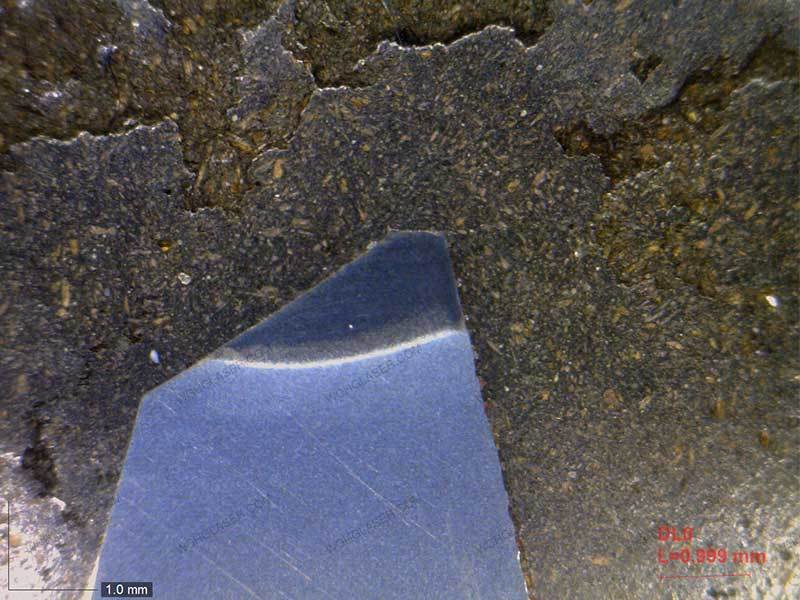

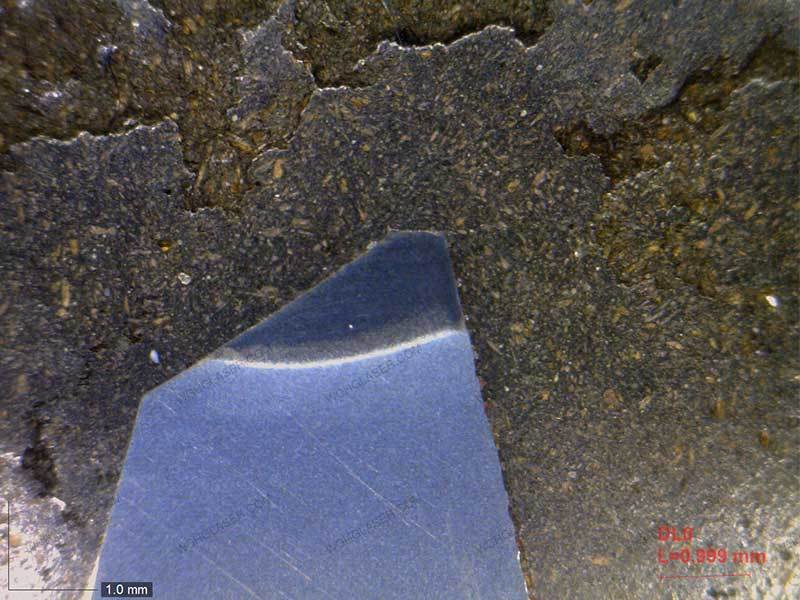

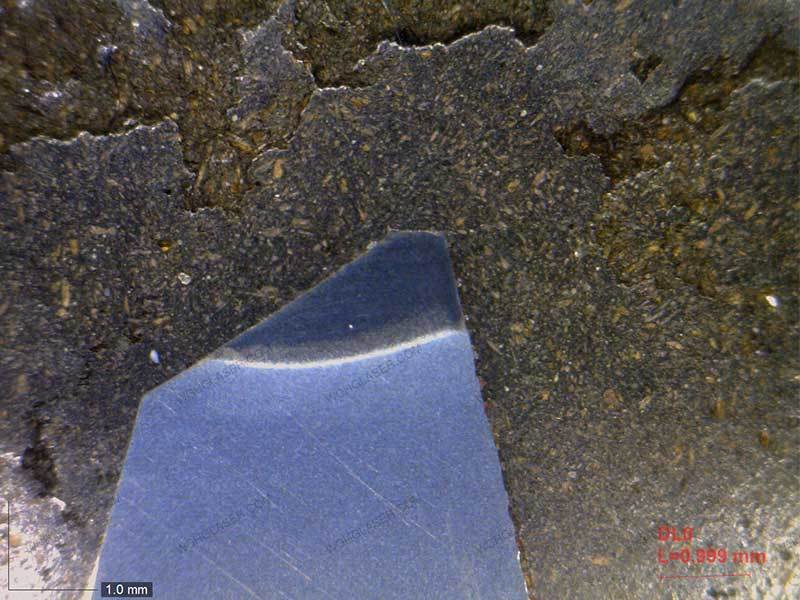

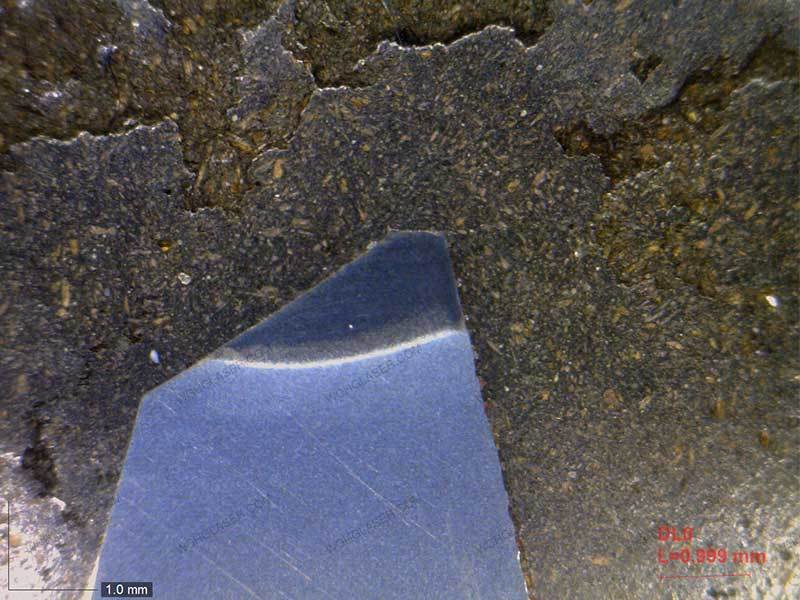

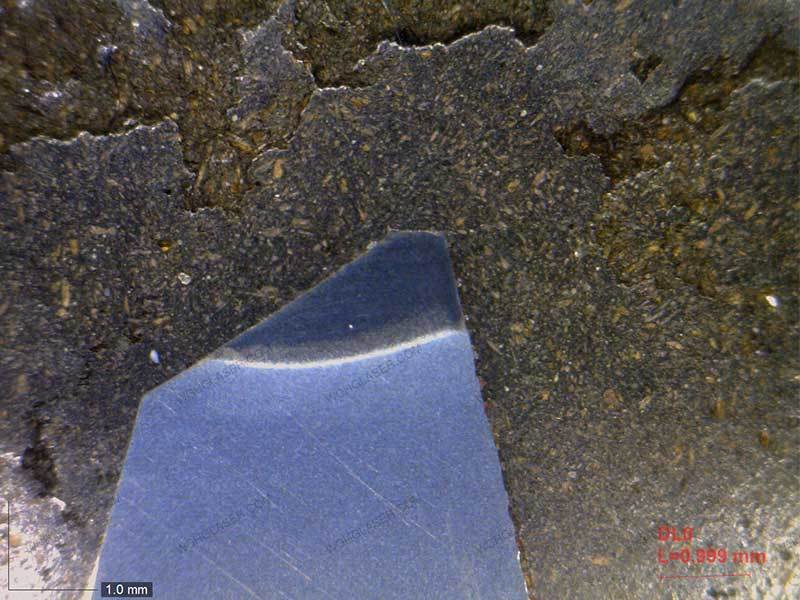

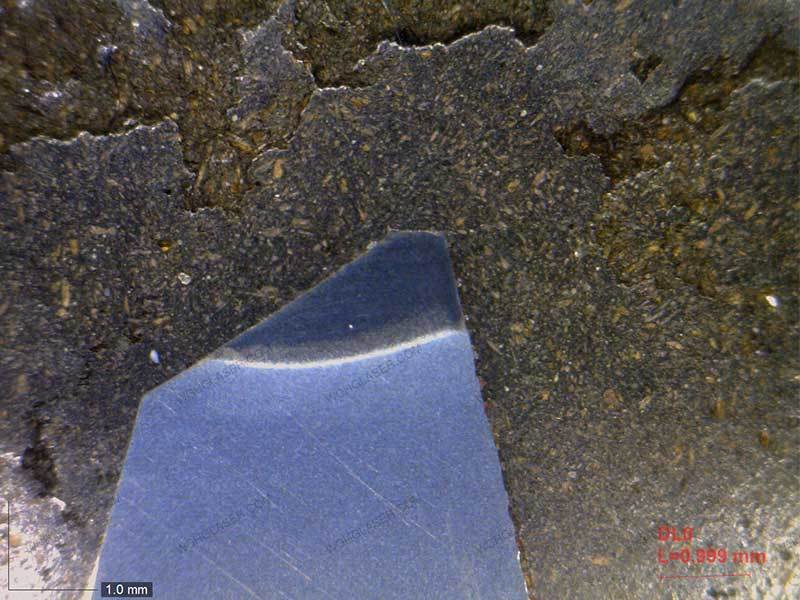

The microstructure of laser quenching for pliers

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

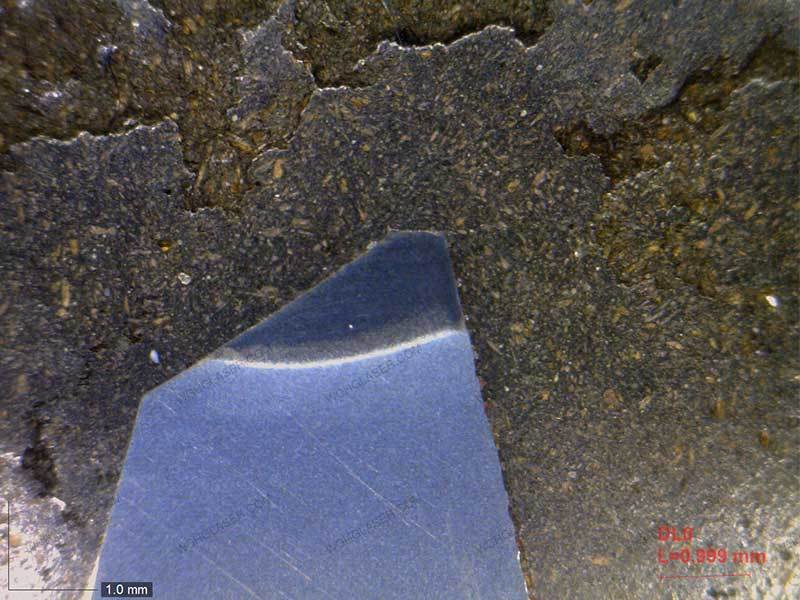

The microstructure of laser quenching for Saw blade

Laser quenching for Vernier caliper

Application industry

Used in the hardware industry, such as saw blades, water pump pliers, vices, cutters, gear racks and other quenching processing.

Categories

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JCK Tool Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: hardware tools.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Characteristics of laser quenching process: the hardening layer has a controllable depth, small heat effect, high hardness and good wear resistance and is not easy to deformation and decarburization to improve service life of the product, without the post process treatment required.

Characteristics of laser cladding technology: laser cladding has high bonding strength, controllable hardness and small deformation, which makes "good steel needs to be used in the blade" for improving the performance of new products and re-manufacturing and repairing of waste products, so as to improve product life and save cost.

Advantages Introduction:

Compact structure and small volume

Easy to install and operate

Low energy consumption, energy saving and environmental protection

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for Vise

Laser quenching for Vise

Laser quenching for pliers

Laser quenching forSurgical forceps

Laser quenching

The microstructure of laser quenching for pliers

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

The microstructure of laser quenching for Saw blade

Laser quenching for Vernier caliper

Application industry

Used in the hardware industry, such as saw blades, water pump pliers, vices, cutters, gear racks and other quenching processing.

Categories

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JCK Tool Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: hardware tools.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Characteristics of laser quenching process: the hardening layer has a controllable depth, small heat effect, high hardness and good wear resistance and is not easy to deformation and decarburization to improve service life of the product, without the post process treatment required.

Characteristics of laser cladding technology: laser cladding has high bonding strength, controllable hardness and small deformation, which makes "good steel needs to be used in the blade" for improving the performance of new products and re-manufacturing and repairing of waste products, so as to improve product life and save cost.

Advantages Introduction:

Compact structure and small volume

Easy to install and operate

Low energy consumption, energy saving and environmental protection

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for Vise

Laser quenching for Vise

Laser quenching for pliers

Laser quenching forSurgical forceps

Laser quenching

The microstructure of laser quenching for pliers

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

The microstructure of laser quenching for Saw blade

Laser quenching for Vernier caliper

Application industry

Used in the hardware industry, such as saw blades, water pump pliers, vices, cutters, gear racks and other quenching processing.

Categories

Laser Cleaning Equipment Series

JCK Tool Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: hardware tools.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Characteristics of laser quenching process: the hardening layer has a controllable depth, small heat effect, high hardness and good wear resistance and is not easy to deformation and decarburization to improve service life of the product, without the post process treatment required.

Characteristics of laser cladding technology: laser cladding has high bonding strength, controllable hardness and small deformation, which makes "good steel needs to be used in the blade" for improving the performance of new products and re-manufacturing and repairing of waste products, so as to improve product life and save cost.

Advantages Introduction:

Compact structure and small volume

Easy to install and operate

Low energy consumption, energy saving and environmental protection

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for Vise

Laser quenching for Vise

Laser quenching for pliers

Laser quenching forSurgical forceps

Laser quenching

The microstructure of laser quenching for pliers

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

The microstructure of laser quenching for Saw blade

Laser quenching for Vernier caliper

Application industry

Used in the hardware industry, such as saw blades, water pump pliers, vices, cutters, gear racks and other quenching processing.

JCK Tool Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: hardware tools.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Characteristics of laser quenching process: the hardening layer has a controllable depth, small heat effect, high hardness and good wear resistance and is not easy to deformation and decarburization to improve service life of the product, without the post process treatment required.

Characteristics of laser cladding technology: laser cladding has high bonding strength, controllable hardness and small deformation, which makes "good steel needs to be used in the blade" for improving the performance of new products and re-manufacturing and repairing of waste products, so as to improve product life and save cost.

Advantages Introduction:

Compact structure and small volume

Easy to install and operate

Low energy consumption, energy saving and environmental protection

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for Vise

Laser quenching for Vise

Laser quenching for pliers

Laser quenching forSurgical forceps

Laser quenching

The microstructure of laser quenching for pliers

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

The microstructure of laser quenching for Saw blade

Laser quenching for Vernier caliper

Application industry

Used in the hardware industry, such as saw blades, water pump pliers, vices, cutters, gear racks and other quenching processing.

JCK Tool Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Application industry: hardware tools.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Characteristics of laser quenching process: the hardening layer has a controllable depth, small heat effect, high hardness and good wear resistance and is not easy to deformation and decarburization to improve service life of the product, without the post process treatment required.

Characteristics of laser cladding technology: laser cladding has high bonding strength, controllable hardness and small deformation, which makes "good steel needs to be used in the blade" for improving the performance of new products and re-manufacturing and repairing of waste products, so as to improve product life and save cost.

Advantages Introduction:

Technical Parameters

Sample Display

Application industry

Used in the hardware industry, such as saw blades, water pump pliers, vices, cutters, gear racks and other quenching processing.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the Laser strengthened parts in the hardware toolsl industry. lasers are integrated into customized machine tools and control systems to form an economical and dedicated model. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Characteristics of laser quenching process: the hardening layer has a controllable depth, small heat effect, high hardness and good wear resistance and is not easy to deformation and decarburization to improve service life of the product, without the post process treatment required.

Characteristics of laser cladding technology: laser cladding has high bonding strength, controllable hardness and small deformation, which makes "good steel needs to be used in the blade" for improving the performance of new products and re-manufacturing and repairing of waste products, so as to improve product life and save cost.

Advantages Introduction:

| Compact structure and small volume | Easy to install and operate | Low energy consumption, energy saving and environmental protection |

Technical Parameters

| Content | Parameters |

| Laser | 2-6kW, fiber, semiconductor, disc, etc. |

| Robot | Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc. |

| Laser Processing Head | 3-25mm round, square spot, size can be customized |

| Optional Accessories | Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc. |

| Input Voltage | 360-480V Three-Phase Five-Wire System @50-60Hz |

Sample Display

Laser quenching for Vise

Laser quenching for Vise

Laser quenching for pliers

Laser quenching forSurgical forceps

Laser quenching

The microstructure of laser quenching for pliers

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

Laser quenching for Saw blade

The microstructure of laser quenching for Saw blade

Laser quenching for Vernier caliper

Application industry

Used in the hardware industry, such as saw blades, water pump pliers, vices, cutters, gear racks and other quenching processing.