Laser Texturing

Brief introduction:

The laser beam with high energy and high repetition frequency is focused on the roller surface to form a micro molten pool; the micro convex concave body is formed under the action of side blowing gas and centrifugal force, and the texturing lattice with high hardness is obtained by ultra fast cooling. It can make the roller after texturing have a high surface hardness, a controllable shape, and a long service life and improve the production efficiency of the rolling mill. The random signal is used to change the morphology and arrangement of the textured points randomly, so that the surface is of disordered pitted surface structure.

Customer benefits:

Low investment cost/Low operating costs/Good processing quality/High reliability

Application area:

It is used in steel, aluminum, titanium and other industries. It can meet the needs of texturing processing of cold roller, and the texturing requirements of various work rolls such as temper mill, finisher, rolling mill and tandem mill.

Comparison between laser texturing and EDM texturing

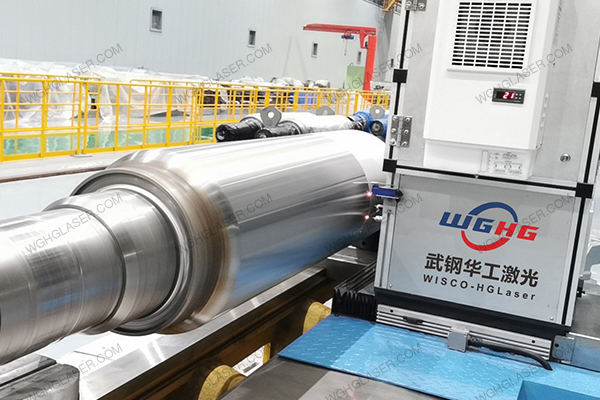

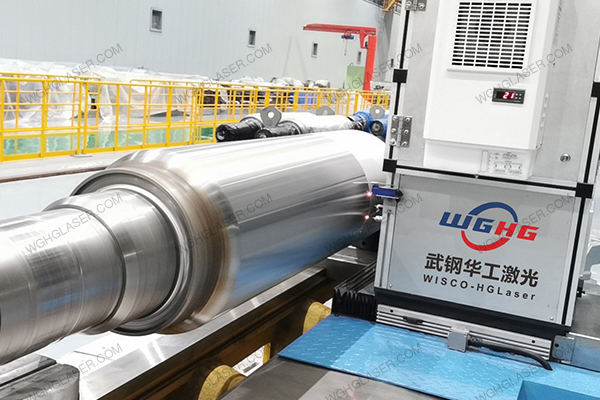

Laser Texturing Equipment

The laser beam with high energy and high repetition frequency is focused on the roller surface to form a micro molten pool; the micro convex concave body is formed under the action of side blowing gas and centrifugal force, and the texturing lattice with high hardness is obtained by ultra fast cooling. It can make the roller after texturing have a high surface hardness, a controllable shape, and a long service life and improve the production efficiency of the rolling mill. The random signal is used to change the morphology and arrangement of the textured points randomly, so that the surface is of disordered pitted surface structure.

Customer benefits:

Low investment cost/Low operating costs/Good processing quality/High reliability

Application area:

It is used in steel, aluminum, titanium and other industries. It can meet the needs of texturing processing of cold roller, and the texturing requirements of various work rolls such as temper mill, finisher, rolling mill and tandem mill.

Laser texturing for Roll

Laser texturing for Roll

Laser texturing for U Roll

Laser texturing

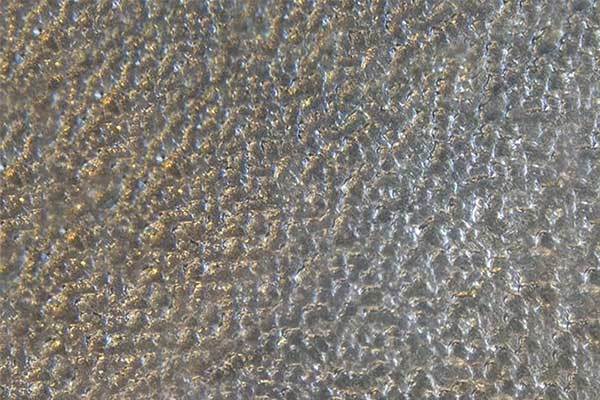

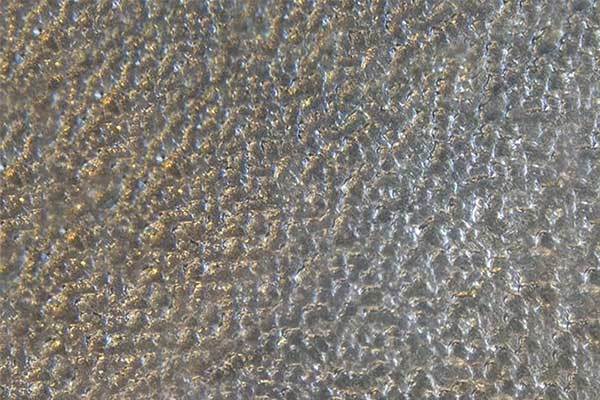

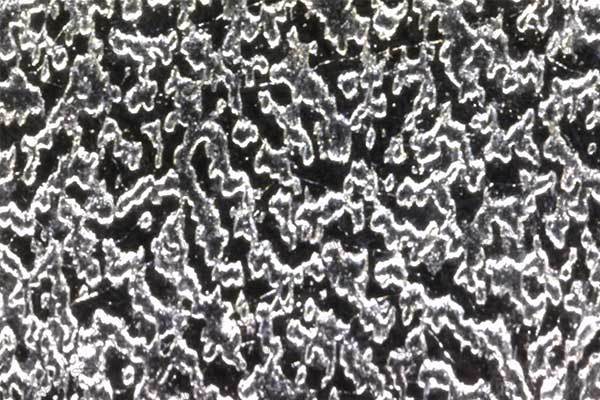

The Surface of Laser texturing

The Surface of LaserTexturing After Zooming in 50

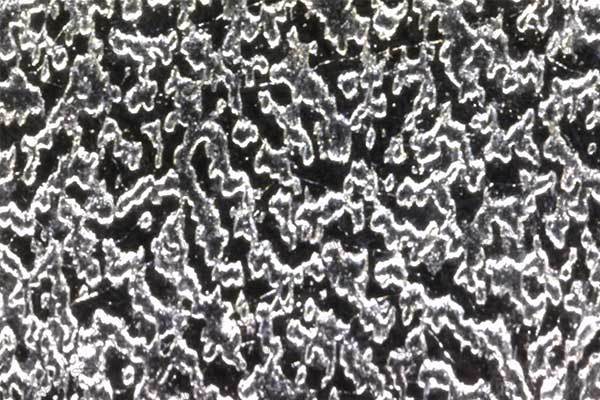

The Surface of Laser Roughening after zooming in 60

The Surface of Laser Roughening after zooming in 200

Comparison between laser texturing and EDM texturing

| Comparison | EDM texturing | Laser texturing |

| Installation conditions | Large area, complex installation and high capital construction cost | Low foundation and infrastructure cost of CNC machine tools |

| Operating cost | Large power consumption, insulating oil and electrode consumption | Low power consumption, no processing consumption |

| Production environment | Serious oil and gas pollution | Pollution-free |

| Surface roughness Ra | 0.5-12 | 0.5-15 |

| Peak number RPc | 50-60 | 100-120 |

| Adjustability of shape | Nonadjustable arrangement and shape of texturing spots | Adjustable arrangement and shape of texturing spots and wide product development |

| Rolling capacity | Formed sharp burr, easy to wear, no improvement | High hardness of the formed concave convex and increase the rolling capacity by 1 time |

Laser Texturing Equipment