Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

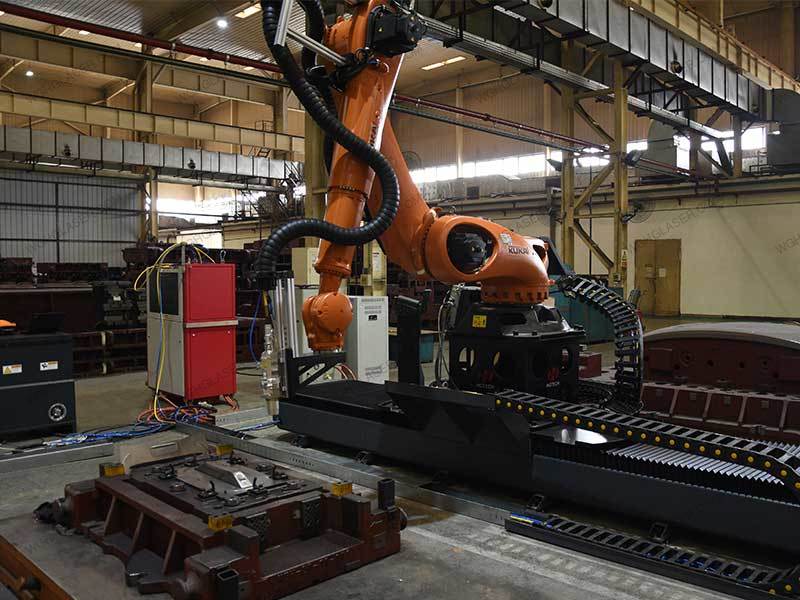

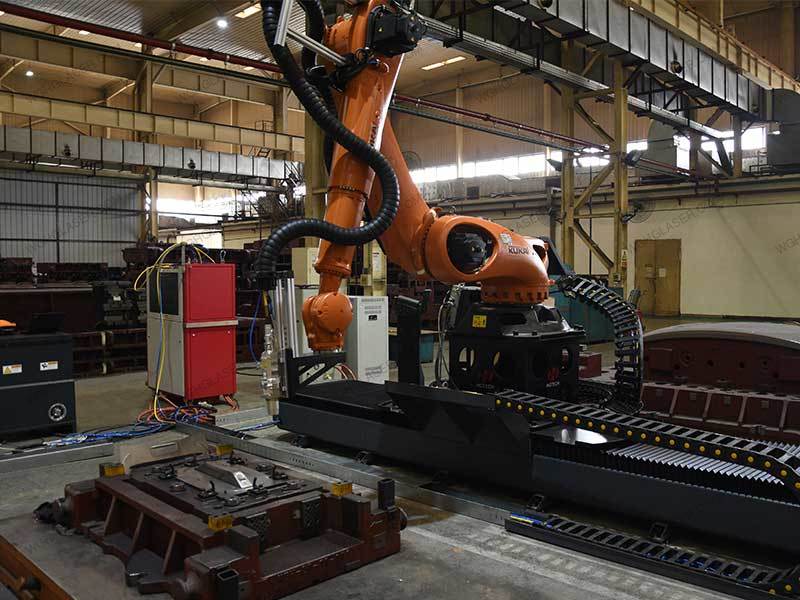

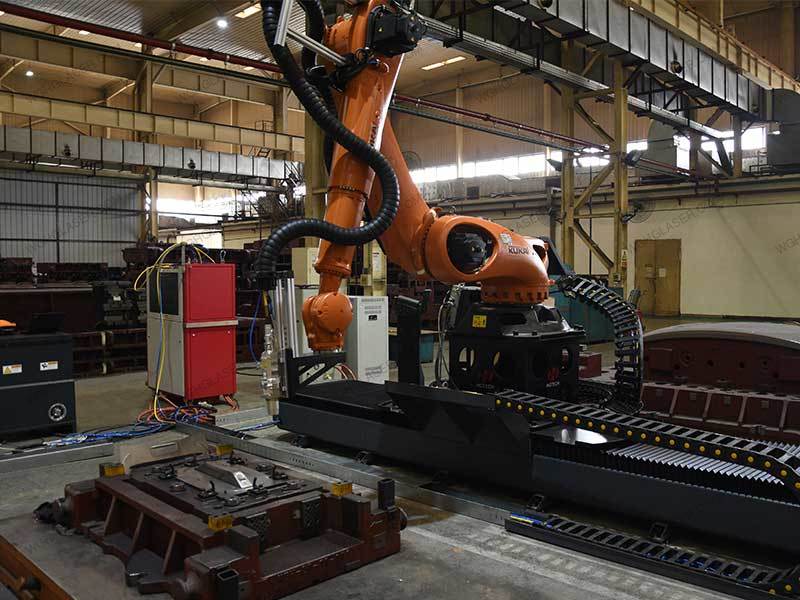

RCW mold laser quenching equipment

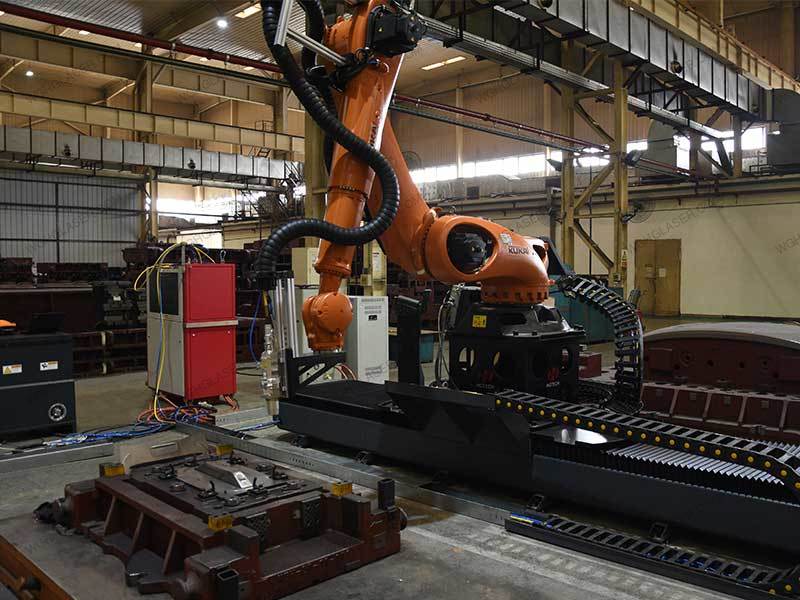

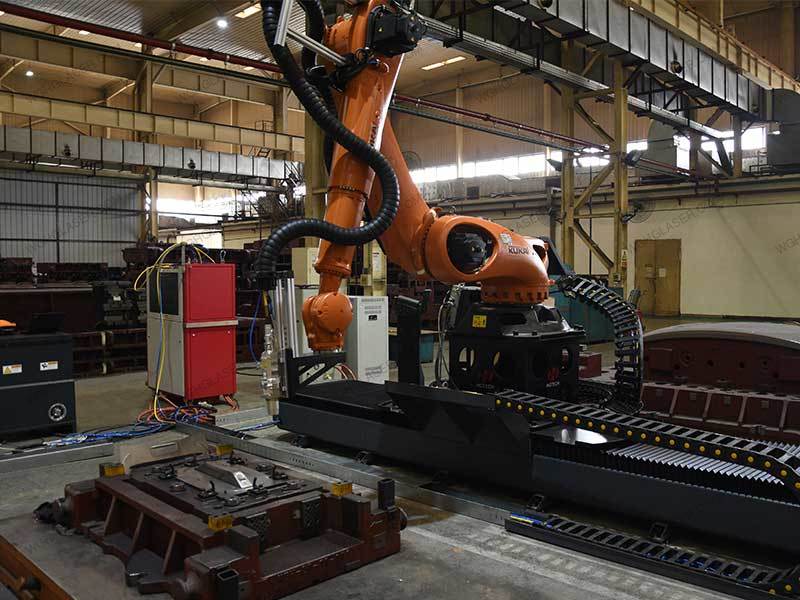

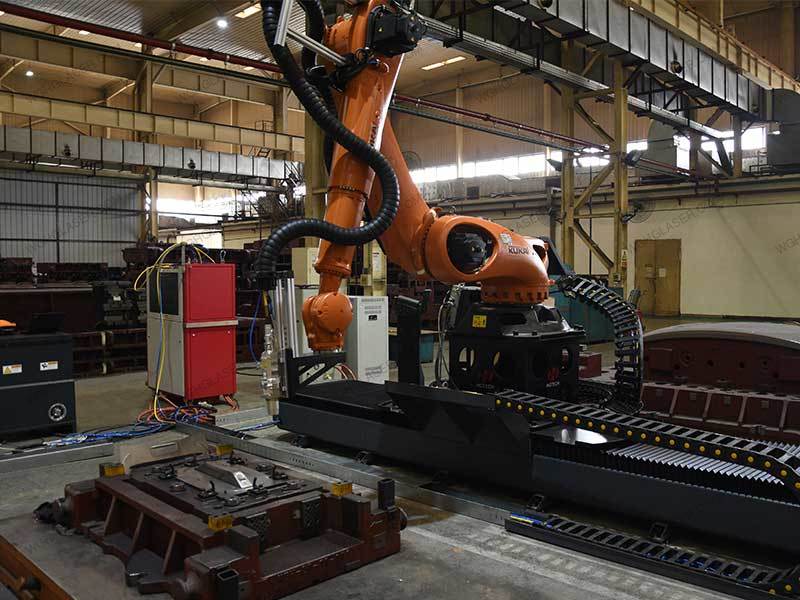

Product Description: It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

-

Application industry: Mould industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

mold laser quenching equipment It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Advantages Introduction:

High efficiency

High quality

High intelligence

It can perform laser quenching and repair processing on complex curved surfaces of large molds

Accurately control the quenching temperature and quality in a closed loop manner.

The equipment can directly generate the quenching head track through digital-analog introduction,

Structure Type

RCW mold laser quenching equipment (floor fixing structure)

RCW mold laser quenching equipment (gantry structure)

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

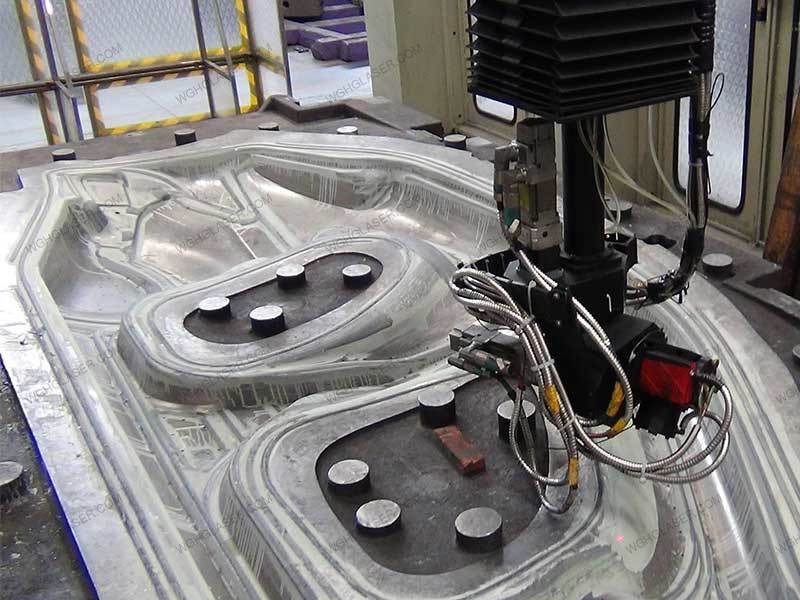

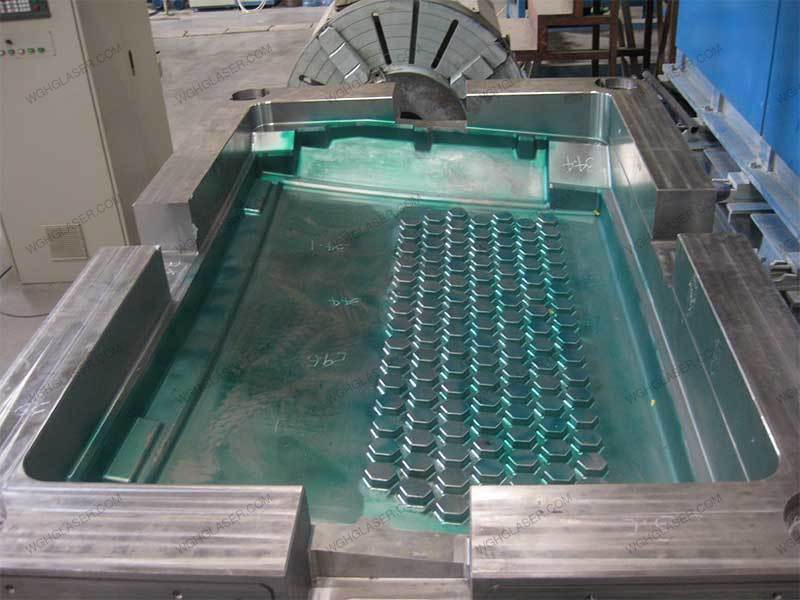

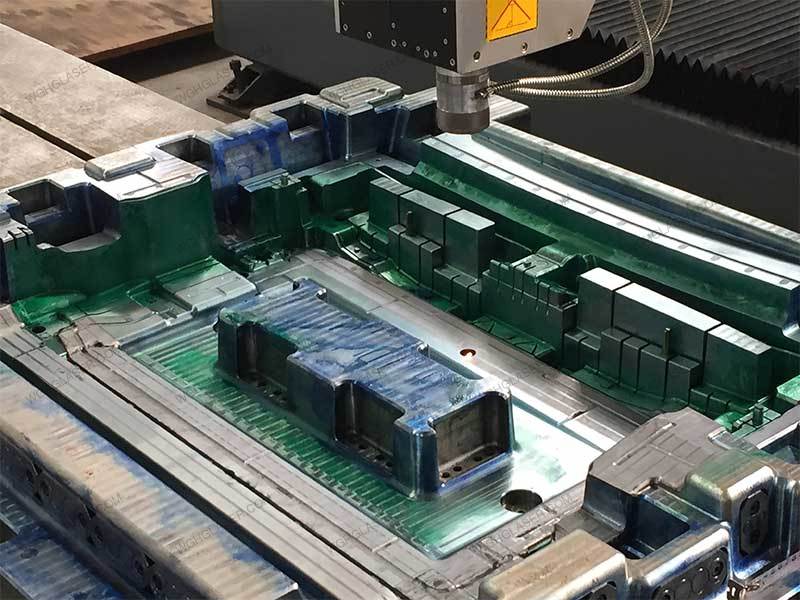

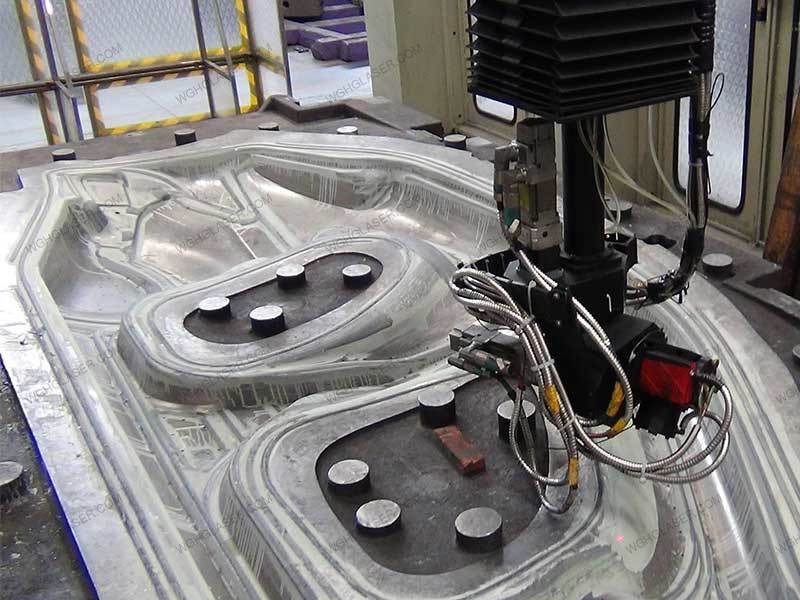

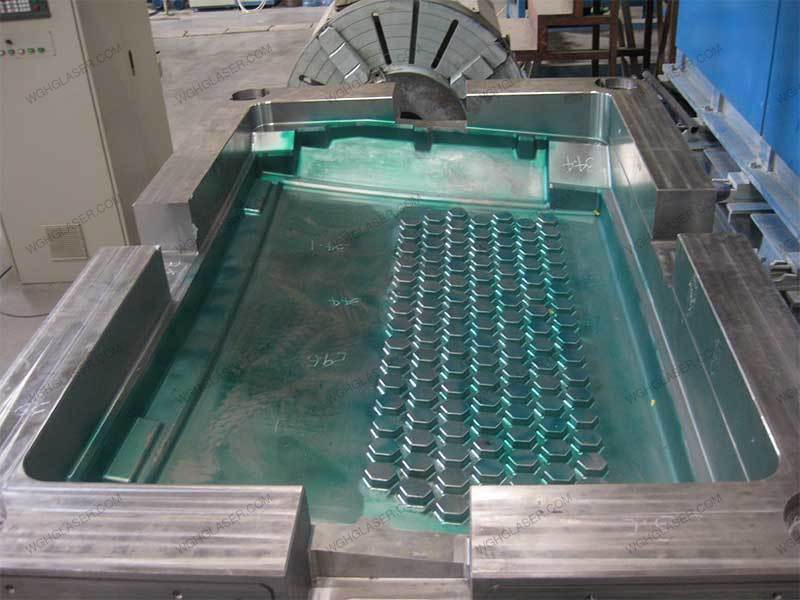

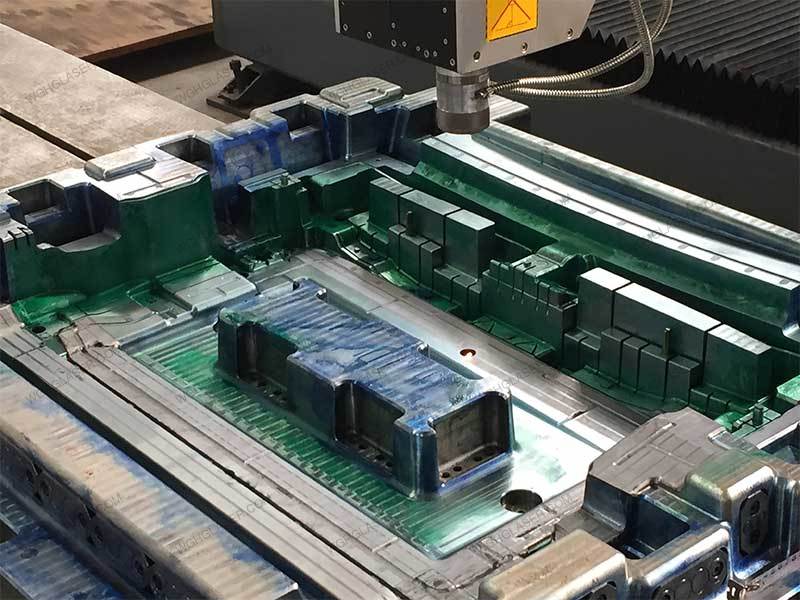

Sample Display

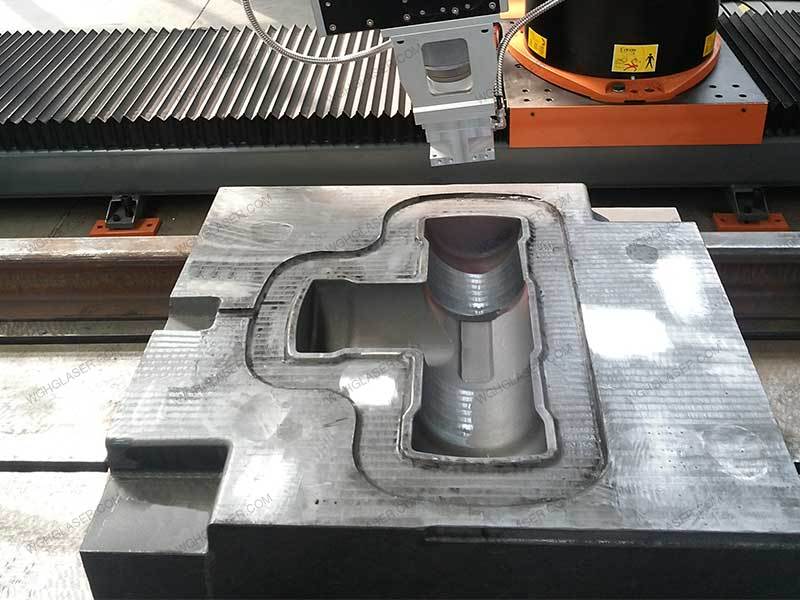

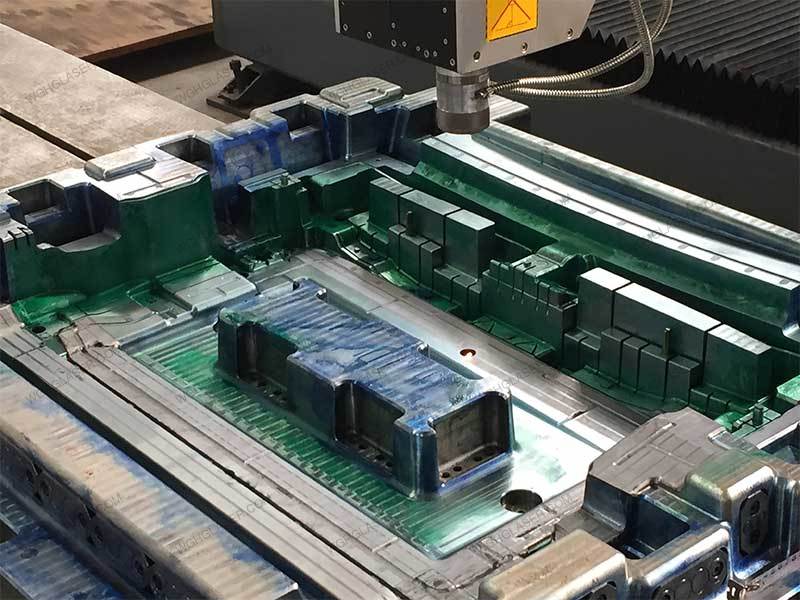

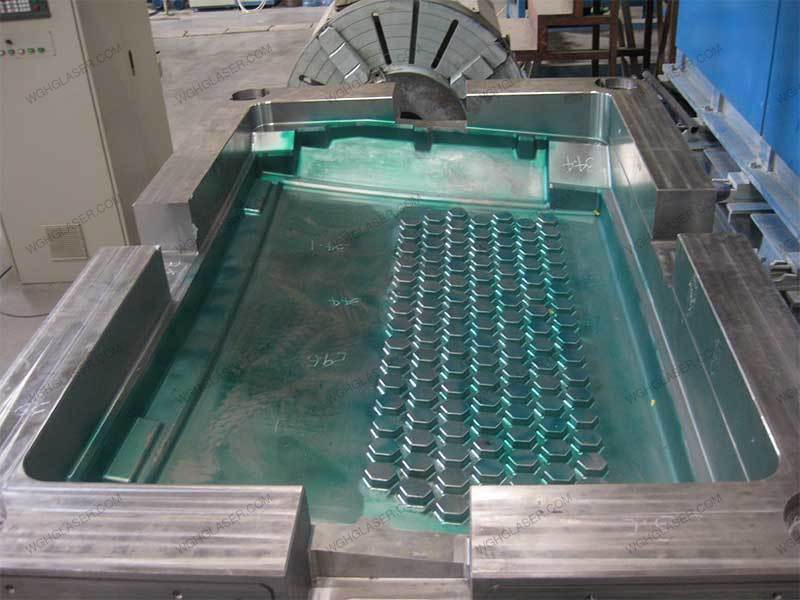

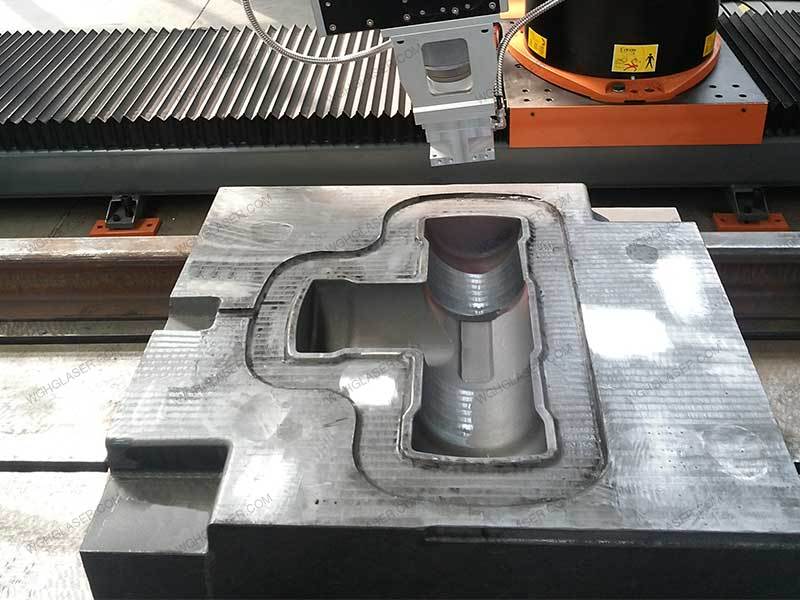

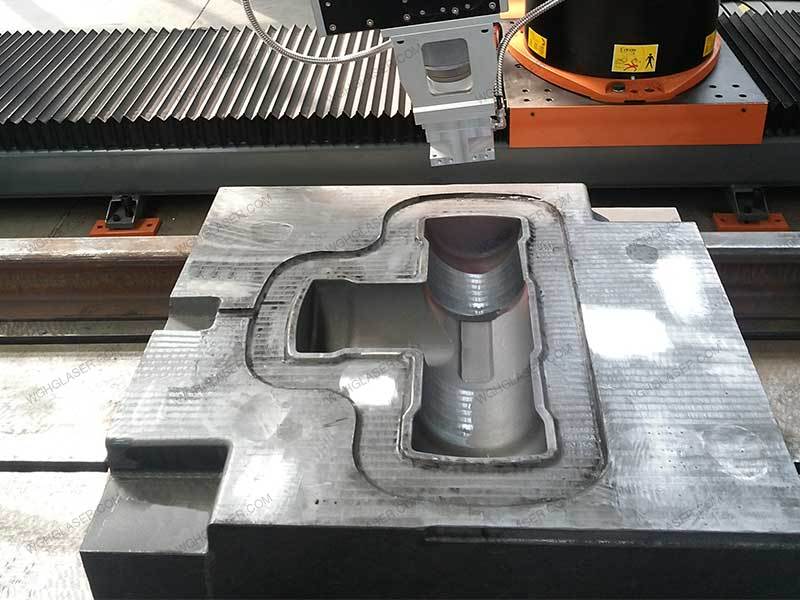

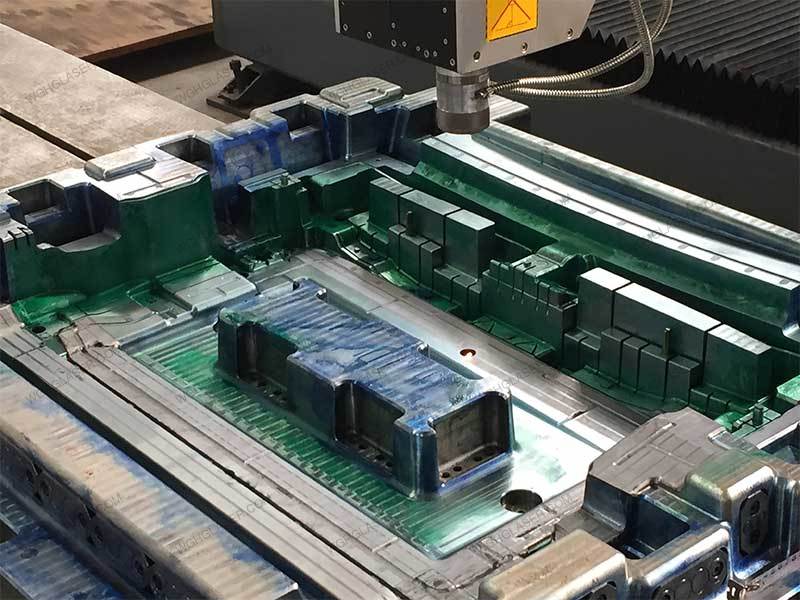

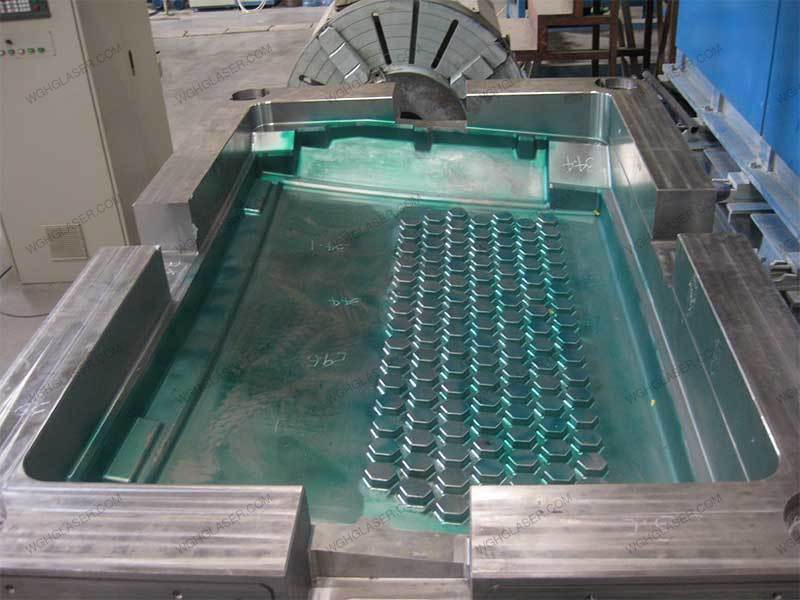

Laser repairing for mold

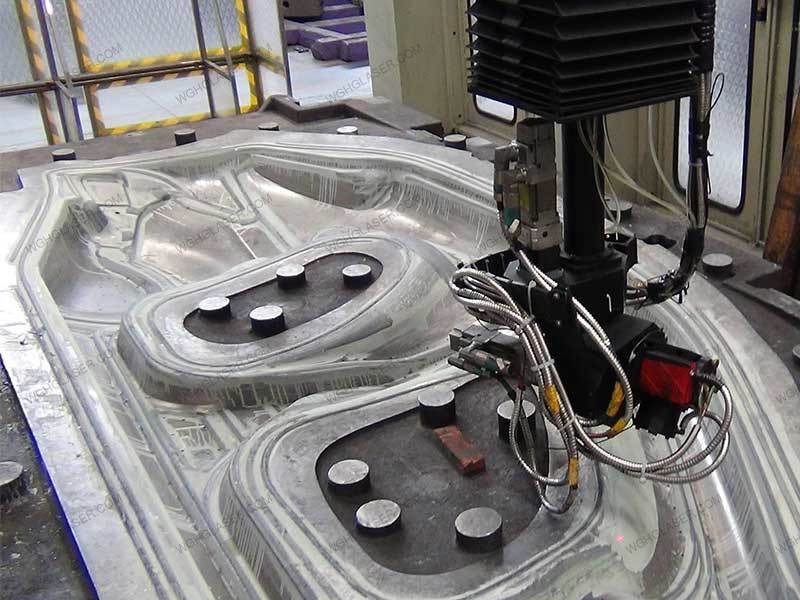

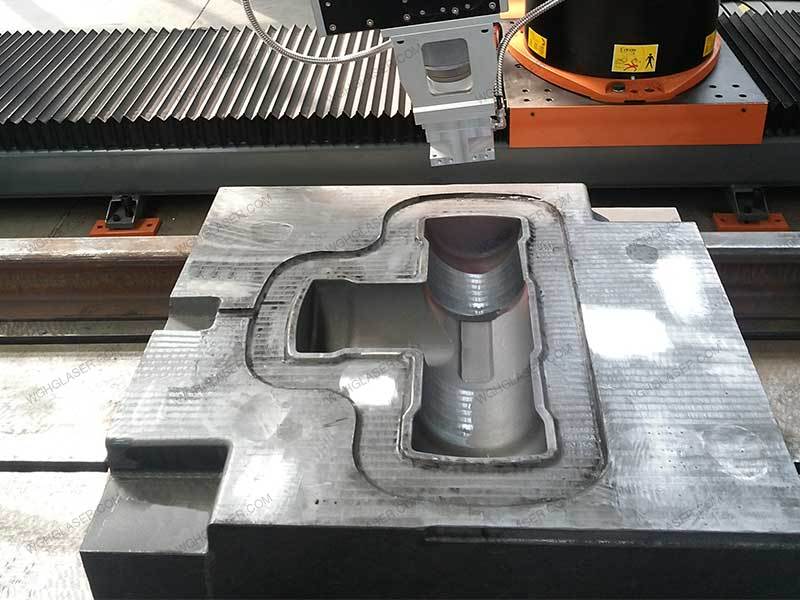

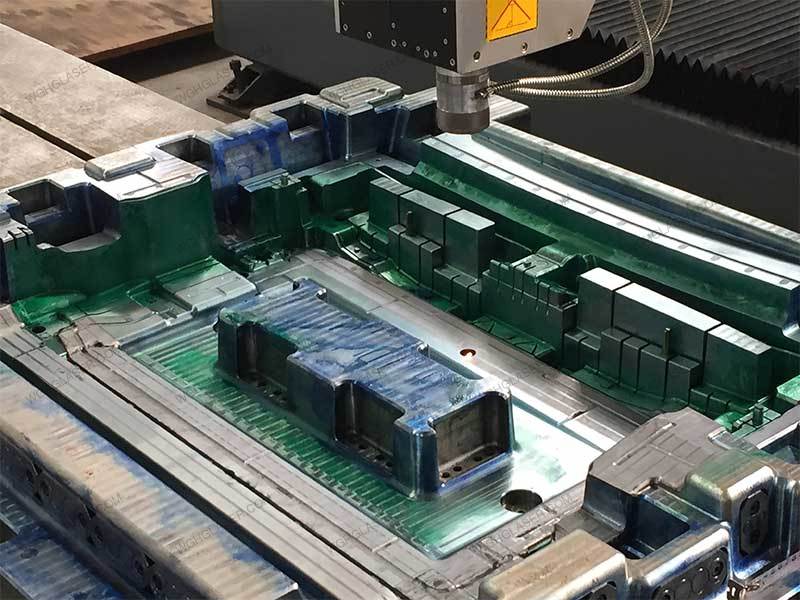

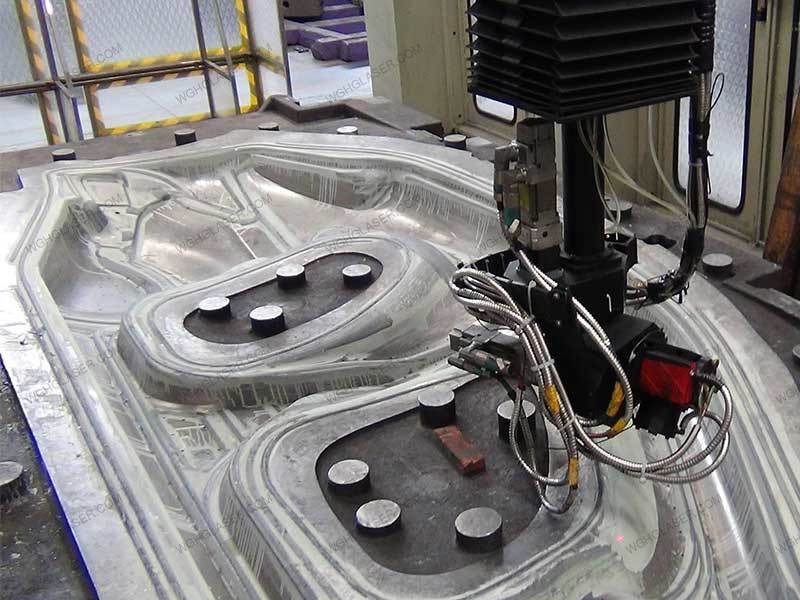

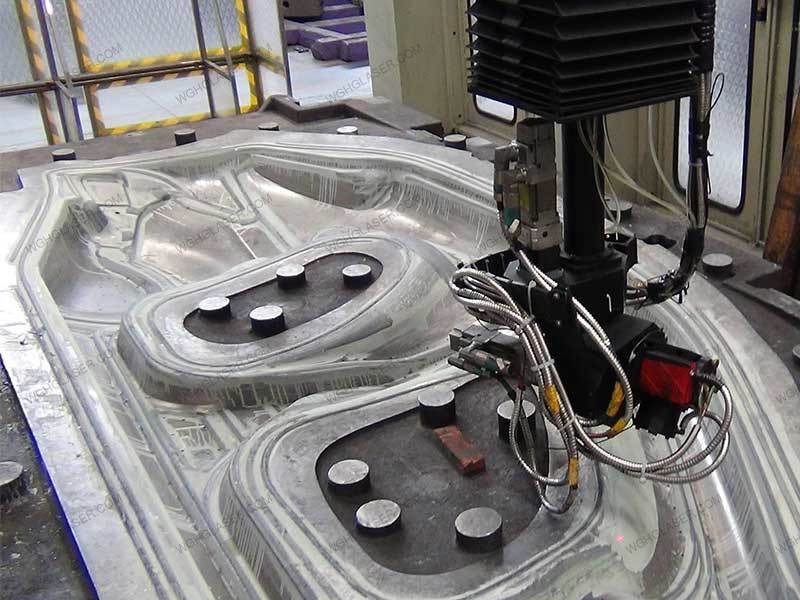

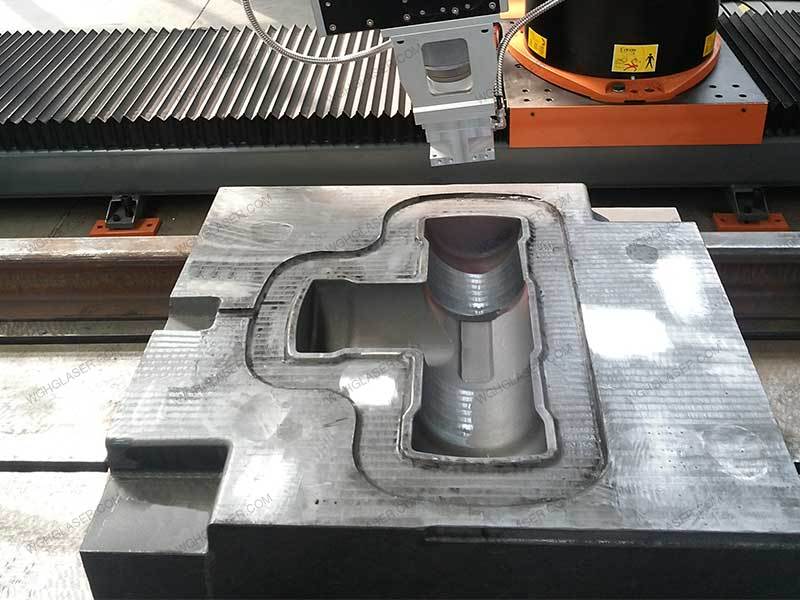

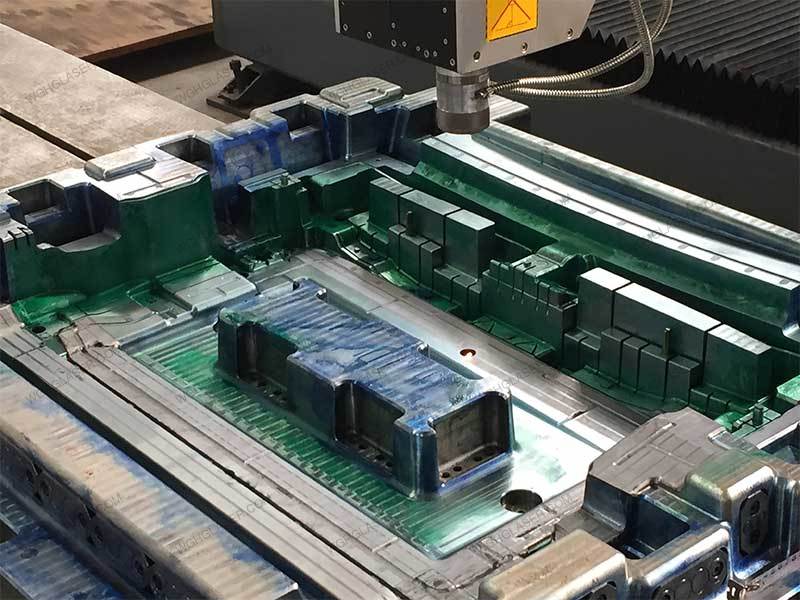

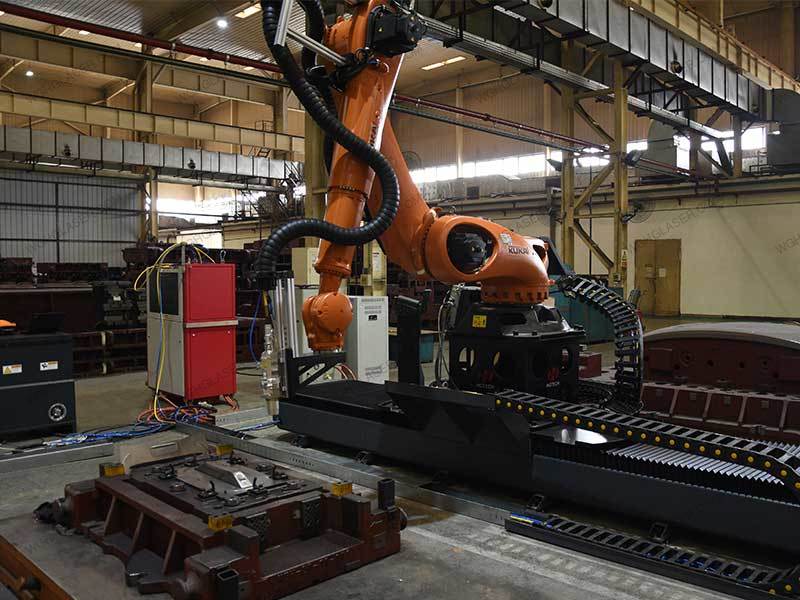

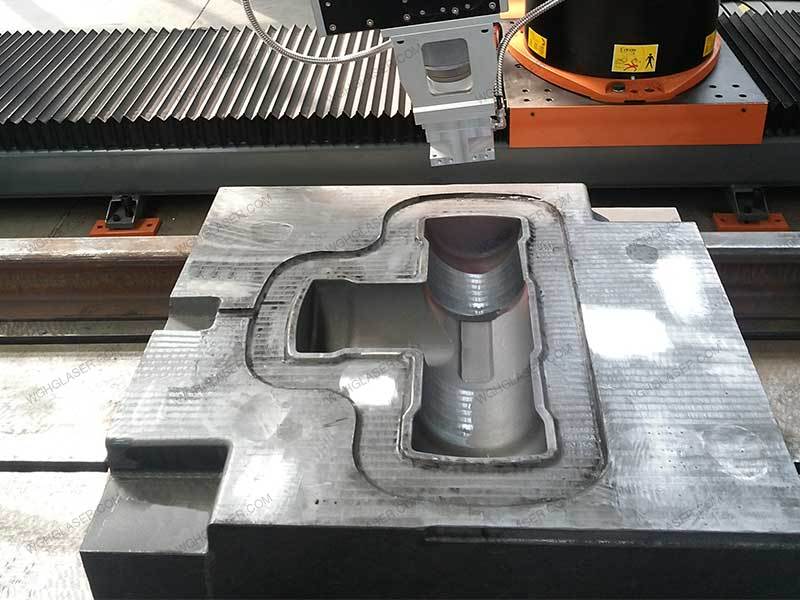

Laser quenching for mold

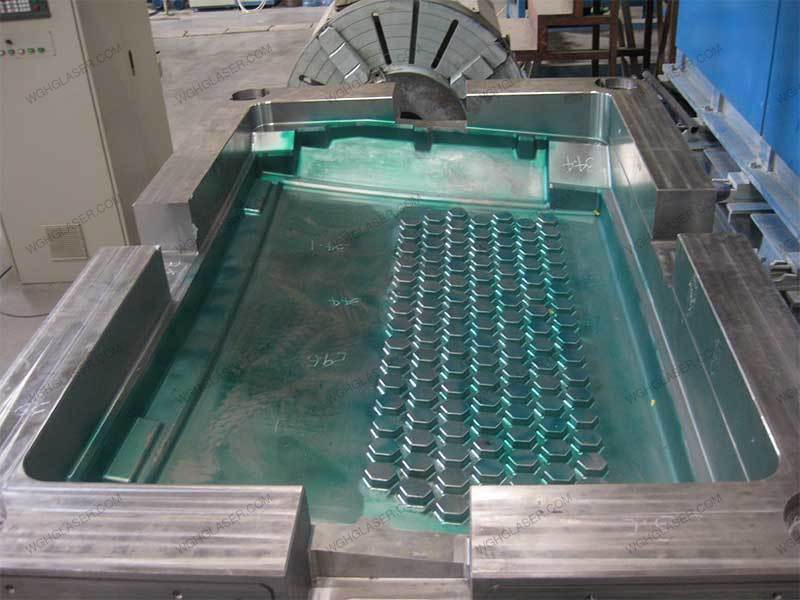

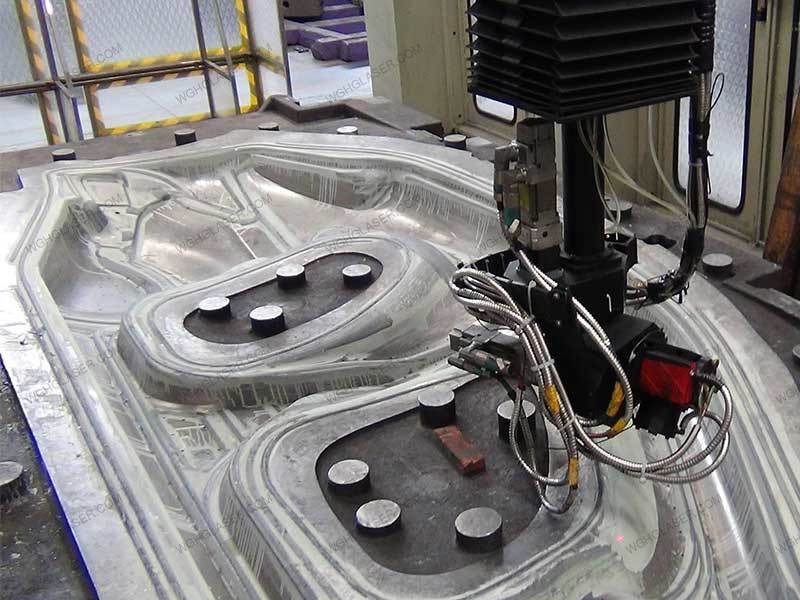

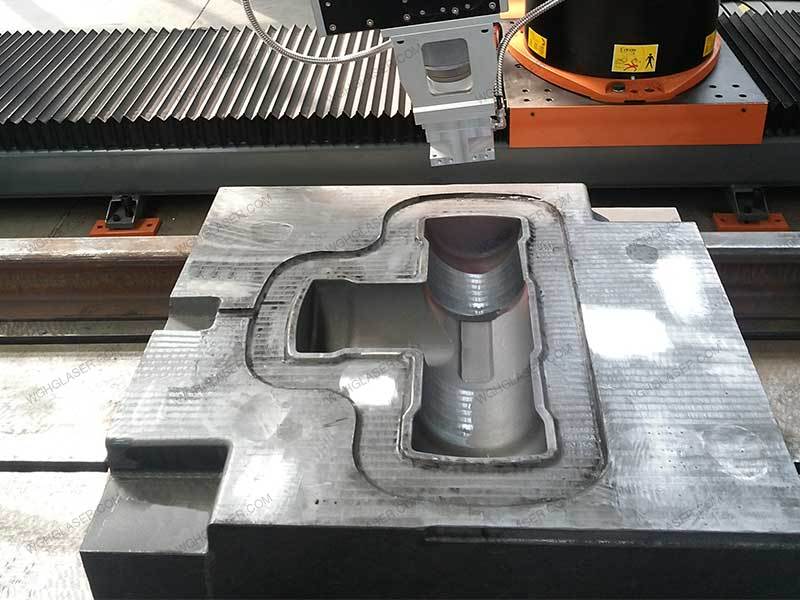

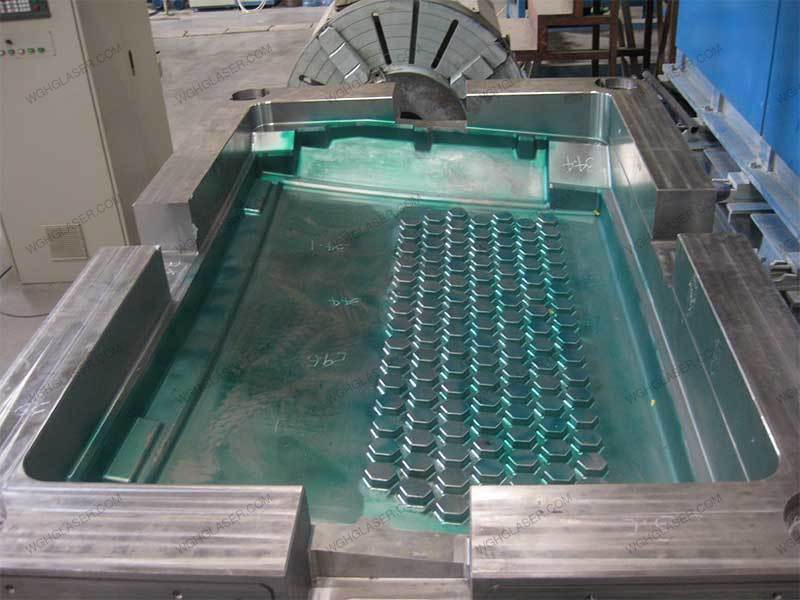

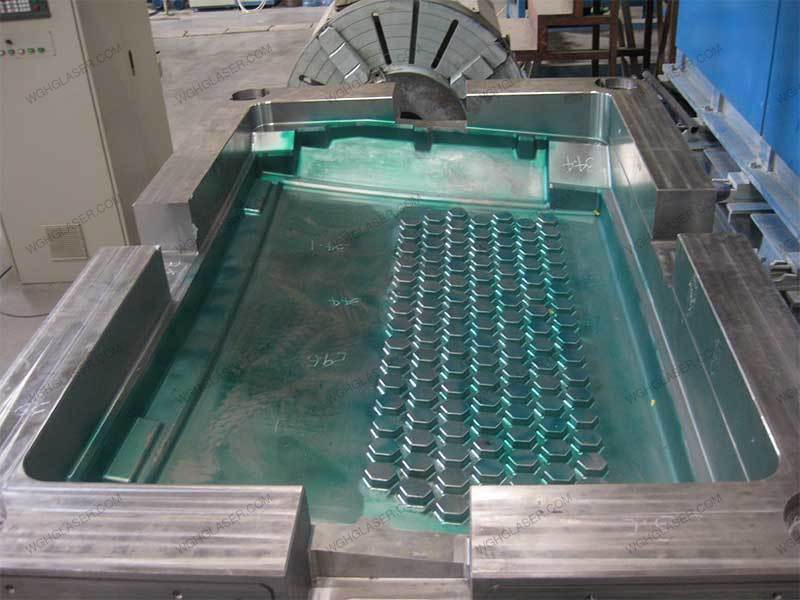

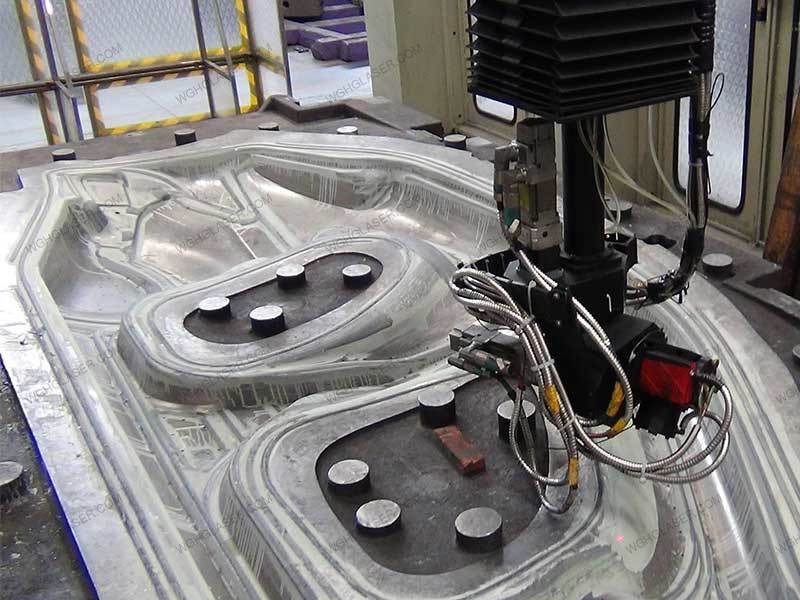

Laser quenching for mold

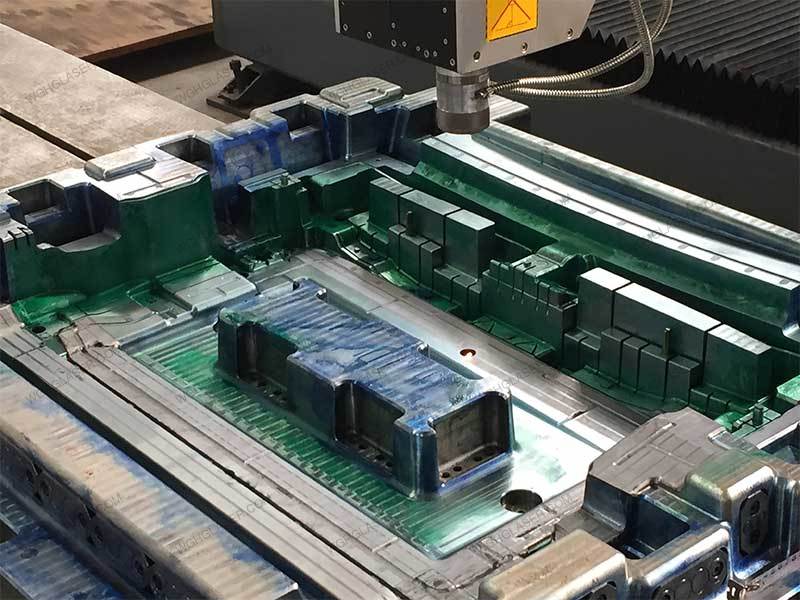

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Application industry

Used for laser quenching of molds in the mold industry.

Categories

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

RCW mold laser quenching equipment

Product Description: It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

-

Application industry: Mould industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

mold laser quenching equipment It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Advantages Introduction:

High efficiency

High quality

High intelligence

It can perform laser quenching and repair processing on complex curved surfaces of large molds

Accurately control the quenching temperature and quality in a closed loop manner.

The equipment can directly generate the quenching head track through digital-analog introduction,

Structure Type

RCW mold laser quenching equipment (floor fixing structure)

RCW mold laser quenching equipment (gantry structure)

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Application industry

Used for laser quenching of molds in the mold industry.

Categories

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

RCW mold laser quenching equipment

Product Description: It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

-

Application industry: Mould industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

mold laser quenching equipment It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Advantages Introduction:

High efficiency

High quality

High intelligence

It can perform laser quenching and repair processing on complex curved surfaces of large molds

Accurately control the quenching temperature and quality in a closed loop manner.

The equipment can directly generate the quenching head track through digital-analog introduction,

Structure Type

RCW mold laser quenching equipment (floor fixing structure)

RCW mold laser quenching equipment (gantry structure)

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Application industry

Used for laser quenching of molds in the mold industry.

Categories

Laser Cleaning Equipment Series

RCW mold laser quenching equipment

Product Description: It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

-

Application industry: Mould industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

mold laser quenching equipment It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Advantages Introduction:

High efficiency

High quality

High intelligence

It can perform laser quenching and repair processing on complex curved surfaces of large molds

Accurately control the quenching temperature and quality in a closed loop manner.

The equipment can directly generate the quenching head track through digital-analog introduction,

Structure Type

RCW mold laser quenching equipment (floor fixing structure)

RCW mold laser quenching equipment (gantry structure)

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Application industry

Used for laser quenching of molds in the mold industry.

RCW mold laser quenching equipment

Product Description: It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

-

Application industry: Mould industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

mold laser quenching equipment It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Advantages Introduction:

High efficiency

High quality

High intelligence

It can perform laser quenching and repair processing on complex curved surfaces of large molds

Accurately control the quenching temperature and quality in a closed loop manner.

The equipment can directly generate the quenching head track through digital-analog introduction,

Structure Type

RCW mold laser quenching equipment (floor fixing structure)

RCW mold laser quenching equipment (gantry structure)

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Application industry

Used for laser quenching of molds in the mold industry.

RCW mold laser quenching equipment

Product Description: It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Application industry: Mould industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

mold laser quenching equipment It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Advantages Introduction:

Structure Type

RCW mold laser quenching equipment (floor fixing structure)

RCW mold laser quenching equipment (gantry structure)

Technical Parameters

Sample Display

Application industry

Used for laser quenching of molds in the mold industry.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

mold laser quenching equipment It adopts advanced laser, advanced industrial robot and control system to form multi-axis linkage flexible laser processing system. Based on the shape and technological requirements of the mould in the Mould industry. The equipment can directly generate the quenching head track through digital-analog introduction, and accurately control the quenching temperature and quality in a closed loop manner. It can perform laser quenching and repair processing on complex curved surfaces of large molds.

Advantages Introduction:

| High efficiency | High quality | High intelligence |

| It can perform laser quenching and repair processing on complex curved surfaces of large molds | Accurately control the quenching temperature and quality in a closed loop manner. | The equipment can directly generate the quenching head track through digital-analog introduction, |

Structure Type

RCW mold laser quenching equipment (floor fixing structure)

| Content | Parameters |

| Laser | 2-6kW, fiber, semiconductor, disc, etc. |

| Robot | Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc. |

| Laser Processing Head | 3-25mm round, square spot, size can be customized |

| Chiller | Single temperature, dual temperature, cooling capacity according to laser selection |

| Optional Accessories | Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc. |

| Input Voltage | 360-480V Three-Phase Five-Wire System @50-60Hz |

Sample Display

Laser repairing for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Laser quenching for mold

Application industry

Used for laser quenching of molds in the mold industry.