Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

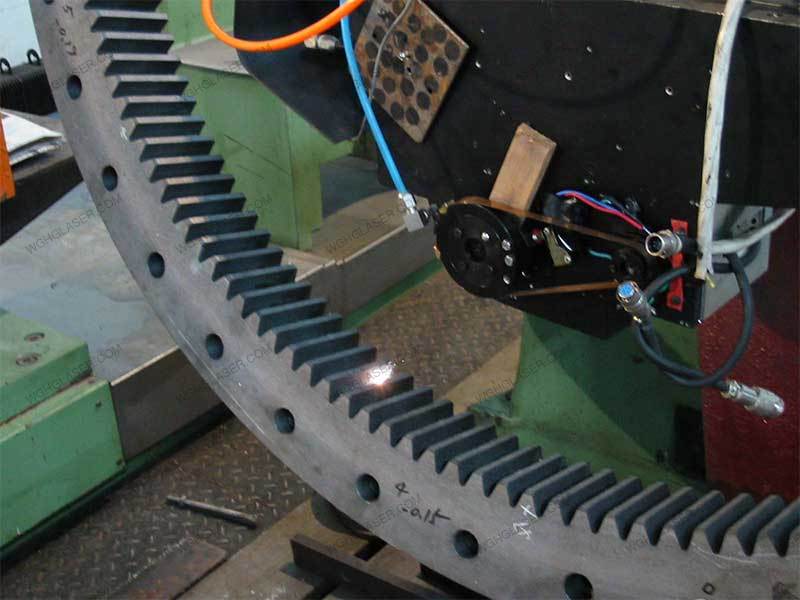

JCK Ring Gear Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: Mechanical Industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of Laser Quenching Equipment and laser cladding on the surface of metal workpiece.

Advantages Introduction:

High conversion rate

Compact structure

Low cost

High efficiency

Short wavelength, high absorption, electro-optic conversion rate up to 45%

Compact structure, easy operation and flexibility

Laser quenching process does not require absorbing coating, reducing the processing cost

Reducing the treatment process of the front and rear processing procedures, and improving the production efficiency

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

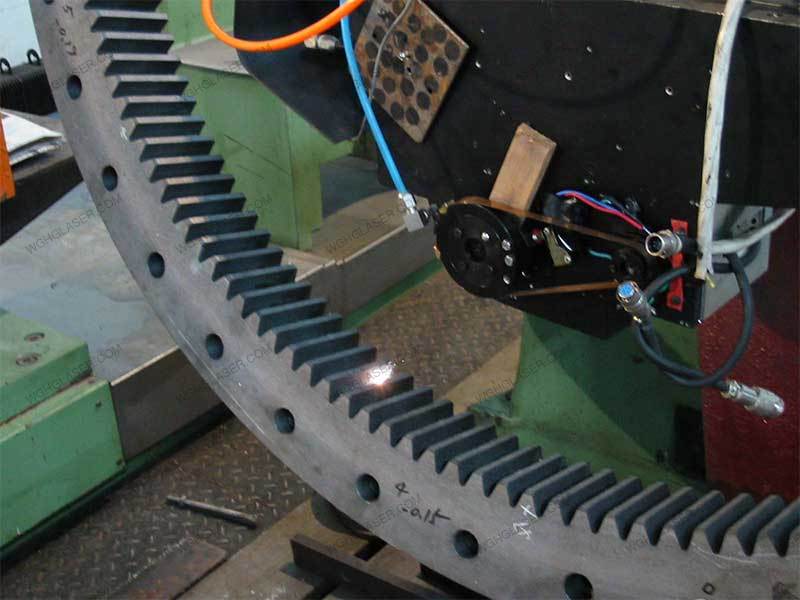

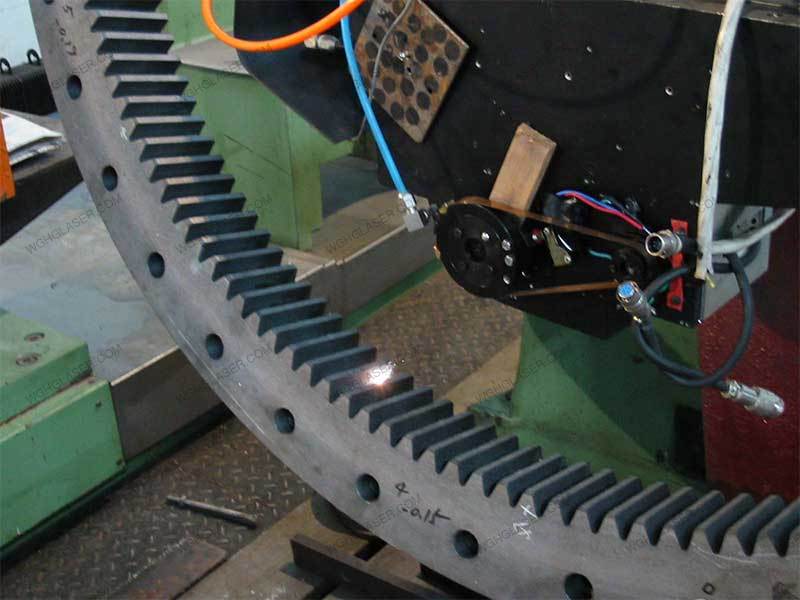

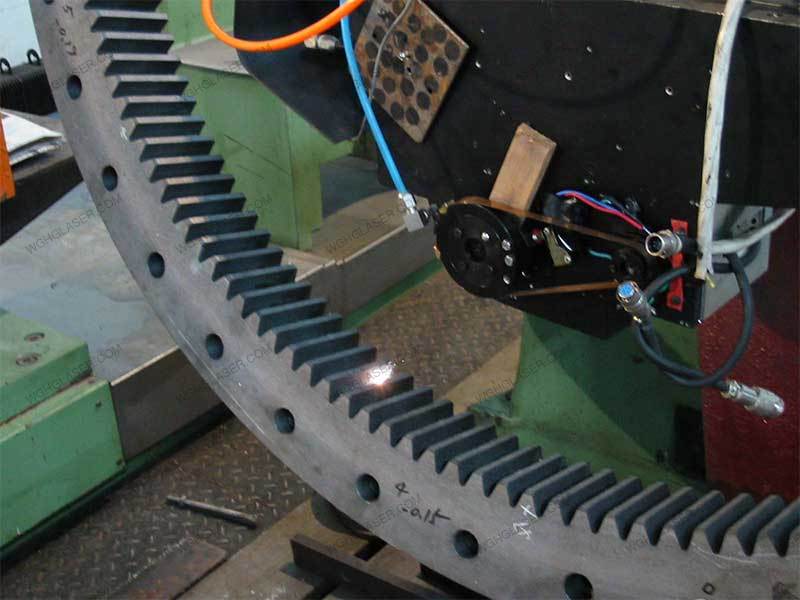

Sample Display

Laser quenching for ring gear

Laser quenching for ring gear

The microstructure of laser quenching for gear

Laser quenching for gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Application industry

It is used for laser quenching of internal and external gear rings, gear quenching of reduction gearbox, and laser quenching of gears and gear rings.

Categories

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

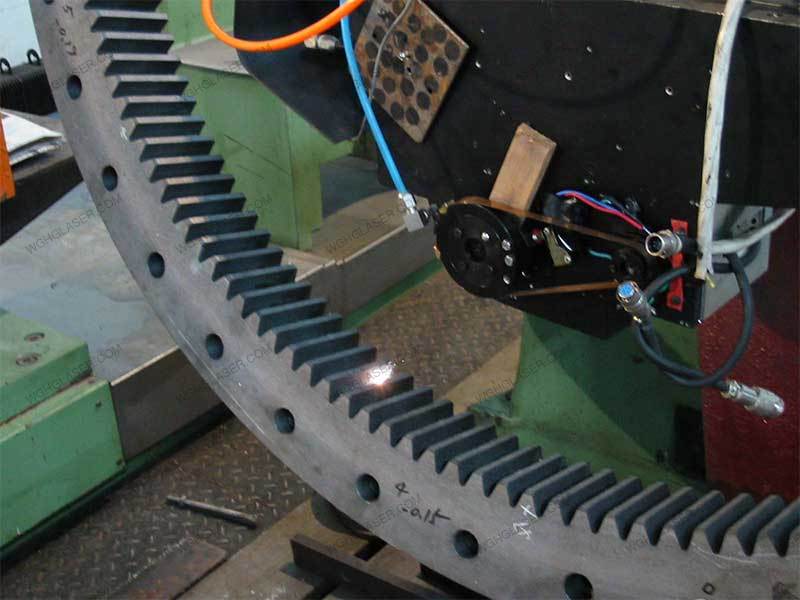

JCK Ring Gear Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: Mechanical Industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of Laser Quenching Equipment and laser cladding on the surface of metal workpiece.

Advantages Introduction:

High conversion rate

Compact structure

Low cost

High efficiency

Short wavelength, high absorption, electro-optic conversion rate up to 45%

Compact structure, easy operation and flexibility

Laser quenching process does not require absorbing coating, reducing the processing cost

Reducing the treatment process of the front and rear processing procedures, and improving the production efficiency

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for ring gear

Laser quenching for ring gear

The microstructure of laser quenching for gear

Laser quenching for gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Application industry

It is used for laser quenching of internal and external gear rings, gear quenching of reduction gearbox, and laser quenching of gears and gear rings.

Categories

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

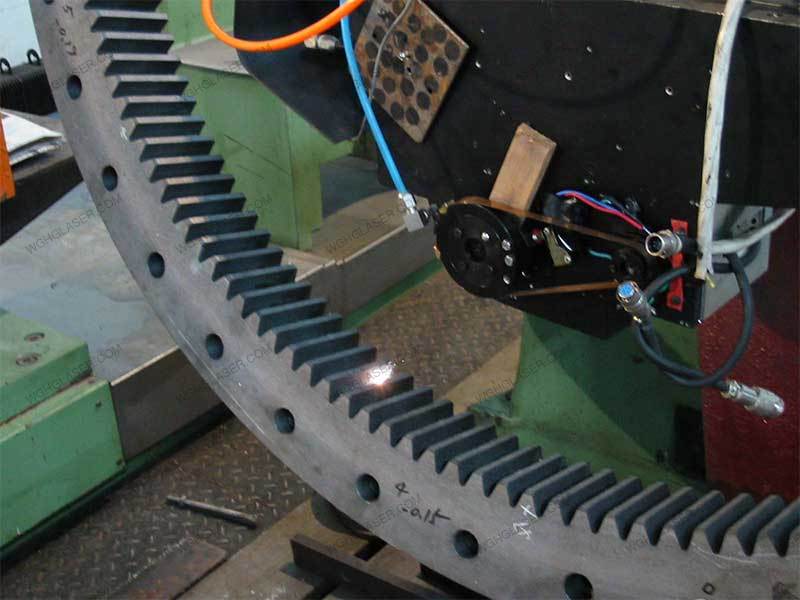

JCK Ring Gear Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: Mechanical Industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of Laser Quenching Equipment and laser cladding on the surface of metal workpiece.

Advantages Introduction:

High conversion rate

Compact structure

Low cost

High efficiency

Short wavelength, high absorption, electro-optic conversion rate up to 45%

Compact structure, easy operation and flexibility

Laser quenching process does not require absorbing coating, reducing the processing cost

Reducing the treatment process of the front and rear processing procedures, and improving the production efficiency

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for ring gear

Laser quenching for ring gear

The microstructure of laser quenching for gear

Laser quenching for gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Application industry

It is used for laser quenching of internal and external gear rings, gear quenching of reduction gearbox, and laser quenching of gears and gear rings.

Categories

Laser Cleaning Equipment Series

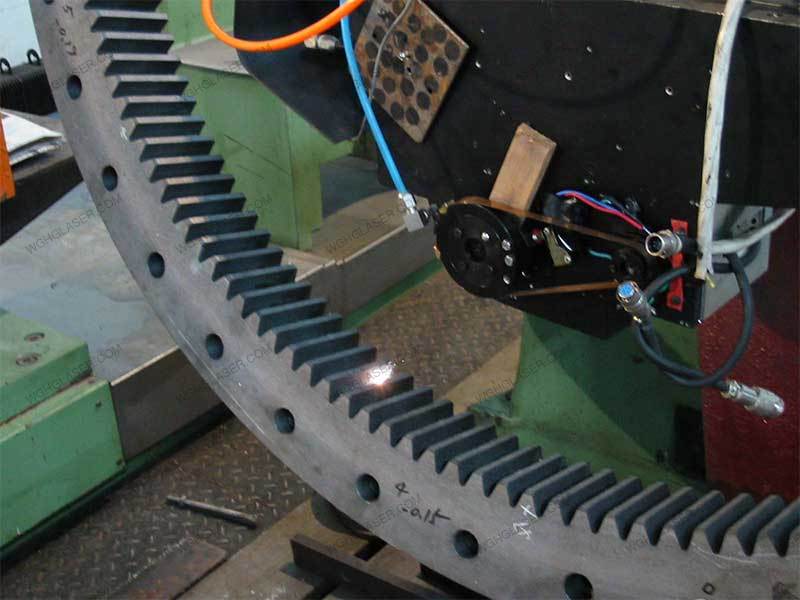

JCK Ring Gear Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: Mechanical Industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of Laser Quenching Equipment and laser cladding on the surface of metal workpiece.

Advantages Introduction:

High conversion rate

Compact structure

Low cost

High efficiency

Short wavelength, high absorption, electro-optic conversion rate up to 45%

Compact structure, easy operation and flexibility

Laser quenching process does not require absorbing coating, reducing the processing cost

Reducing the treatment process of the front and rear processing procedures, and improving the production efficiency

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for ring gear

Laser quenching for ring gear

The microstructure of laser quenching for gear

Laser quenching for gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Application industry

It is used for laser quenching of internal and external gear rings, gear quenching of reduction gearbox, and laser quenching of gears and gear rings.

JCK Ring Gear Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

-

Application industry: Mechanical Industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of Laser Quenching Equipment and laser cladding on the surface of metal workpiece.

Advantages Introduction:

High conversion rate

Compact structure

Low cost

High efficiency

Short wavelength, high absorption, electro-optic conversion rate up to 45%

Compact structure, easy operation and flexibility

Laser quenching process does not require absorbing coating, reducing the processing cost

Reducing the treatment process of the front and rear processing procedures, and improving the production efficiency

Technical Parameters

Content

Parameters

Laser

2-6kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

3-25mm round, square spot, size can be customized

Chiller

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser quenching for ring gear

Laser quenching for ring gear

The microstructure of laser quenching for gear

Laser quenching for gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Application industry

It is used for laser quenching of internal and external gear rings, gear quenching of reduction gearbox, and laser quenching of gears and gear rings.

JCK Ring Gear Laser Quenching Equipment

Product Description: Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of laser quenching and laser cladding on the surface of metal workpiece.

Application industry: Mechanical Industry

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of Laser Quenching Equipment and laser cladding on the surface of metal workpiece.

Advantages Introduction:

Technical Parameters

Sample Display

Application industry

It is used for laser quenching of internal and external gear rings, gear quenching of reduction gearbox, and laser quenching of gears and gear rings.

Applicable materials: cast iron, nodular iron, cast steel, medium carbon steel, high carbon steel and other ferrous metals.

Based on the shape and technological requirements of the ring gear in the mechanical industry, an economic and special laser heat treatment processing equipment is formed by using advanced lasers, customized machine tools and control systems. It can meet the requirements of Laser Quenching Equipment and laser cladding on the surface of metal workpiece.

Advantages Introduction:

| High conversion rate | Compact structure | Low cost | High efficiency |

| Short wavelength, high absorption, electro-optic conversion rate up to 45% | Compact structure, easy operation and flexibility | Laser quenching process does not require absorbing coating, reducing the processing cost | Reducing the treatment process of the front and rear processing procedures, and improving the production efficiency |

Technical Parameters

| Content | Parameters |

| Laser | 2-6kW, fiber, semiconductor, disc, etc. |

| Robot | Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc. |

| Laser Processing Head | 3-25mm round, square spot, size can be customized |

| Chiller | Single temperature, dual temperature, cooling capacity according to laser selection |

| Optional Accessories | Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc. |

| Input Voltage | 360-480V Three-Phase Five-Wire System @50-60Hz |

Sample Display

Laser quenching for ring gear

Laser quenching for ring gear

The microstructure of laser quenching for gear

Laser quenching for gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for ring gear

Laser quenching for gear

Laser quenching for ring gear

Laser quenching for ring gear

Application industry

It is used for laser quenching of internal and external gear rings, gear quenching of reduction gearbox, and laser quenching of gears and gear rings.