Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JKR coal machine hydraulic cylinder laser cladding equipment

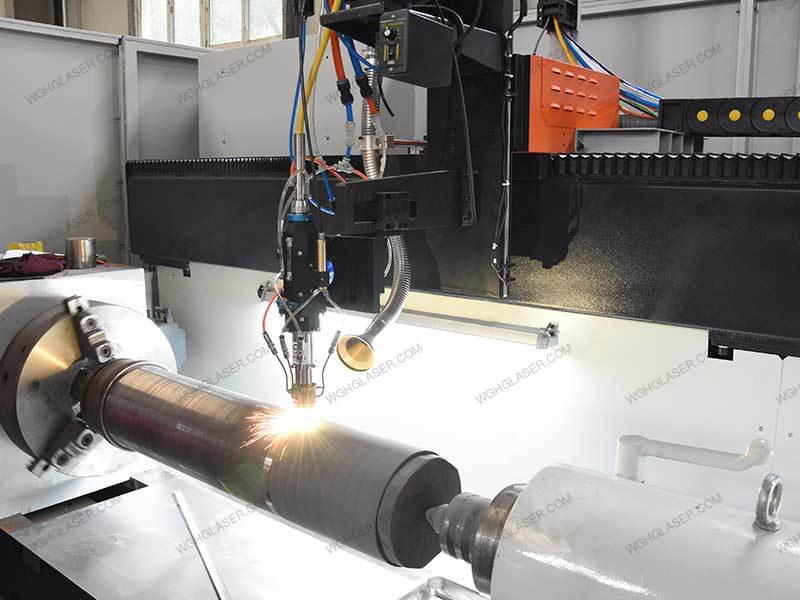

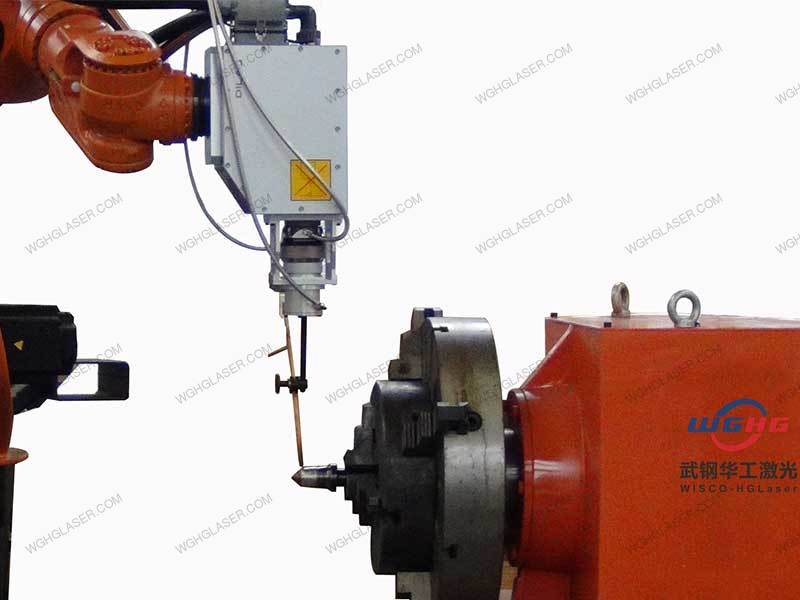

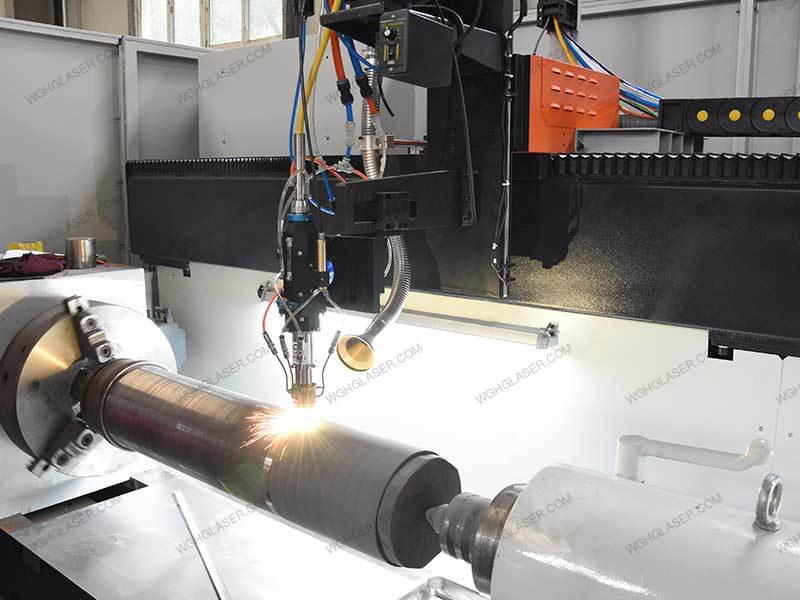

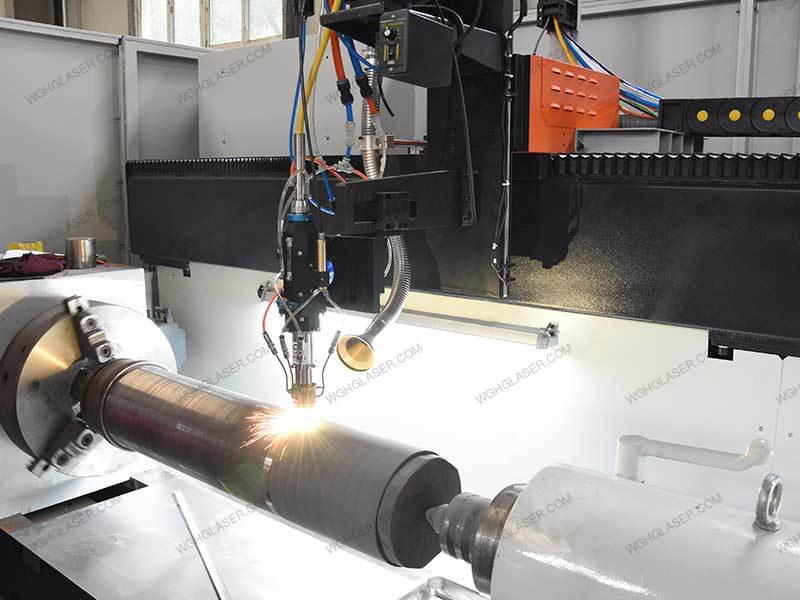

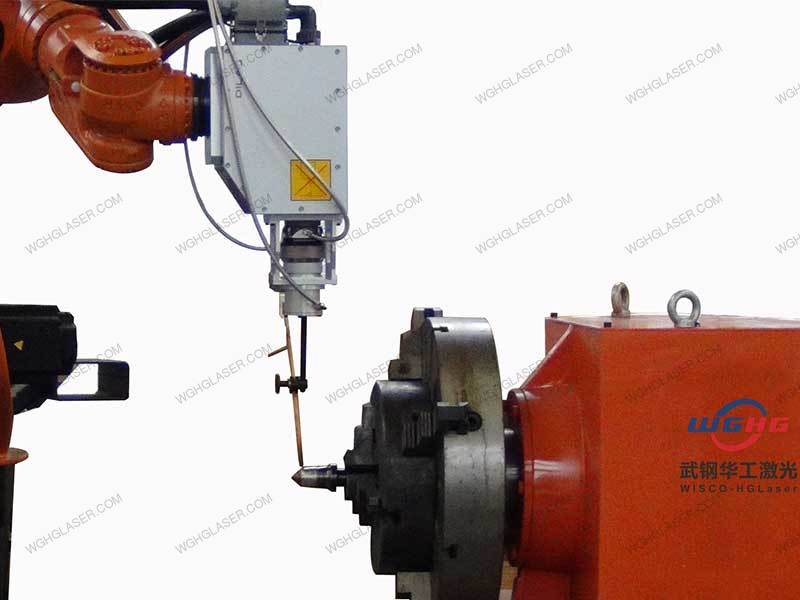

Product Description: Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

-

Application industry: Coal machine industry

Applicable materials: low carbon steel, medium carbon steel, high carbon steel, etc.

Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

WISCO-HGlaser has developed and designed a special laser cladding equipment for Laser Cladding Hydraulic Cylinder in the mining machinery industry, and is capable of forming batch processing equipment in this industry, which can prepare high-performance alloy surface on the metal substrate of parts and components to significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other properties of the workpiece surface. It not only reduces the cost, but improves the service life, which is more beneficial to environmental protection.

Advantages Introduction:

High cost performance ratio

Precisely controllable

Stable and reliable

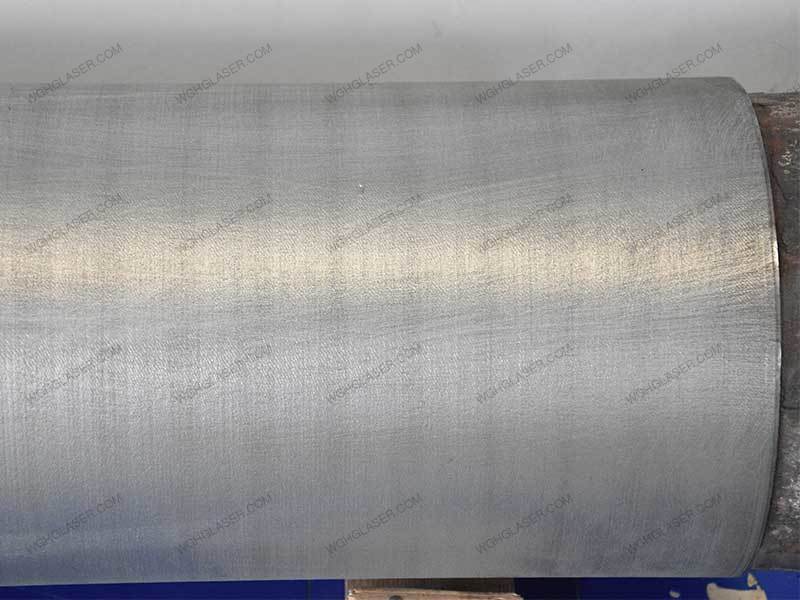

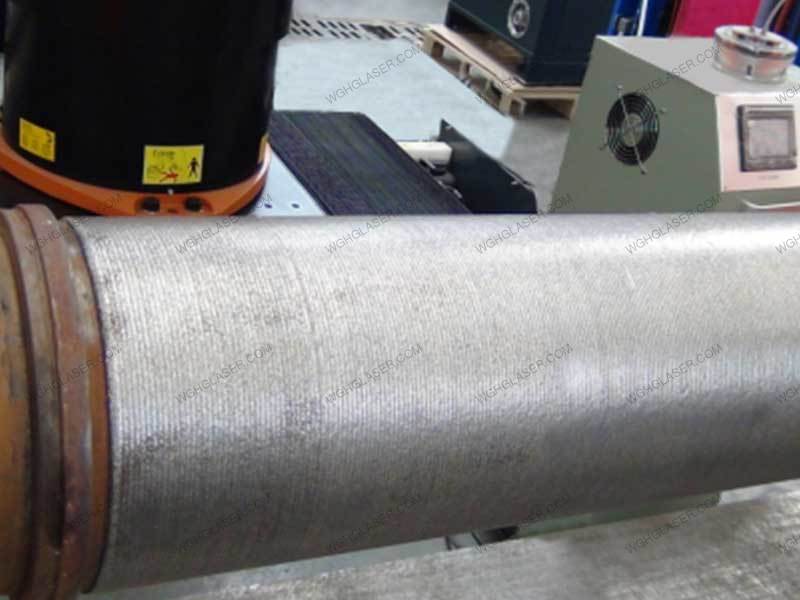

High density of cladding layer

The whole machine is simple in structure, low in comprehensive maintenance cost, high in efficiency and high in reliability.

Accurate and controllable laser position, controllable temperature feedback, controllable processing process and high efficiency.

Modular design, real-time data monitoring, low failure rate, close to maintenance free.

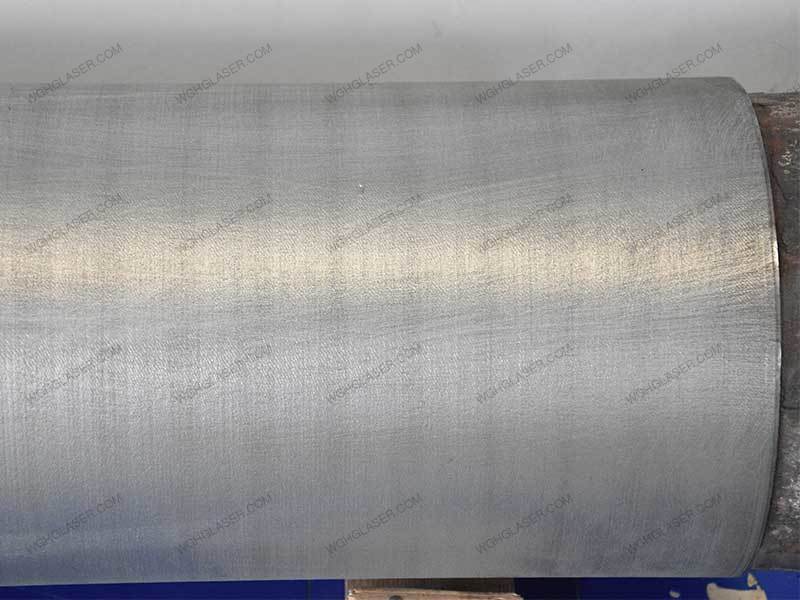

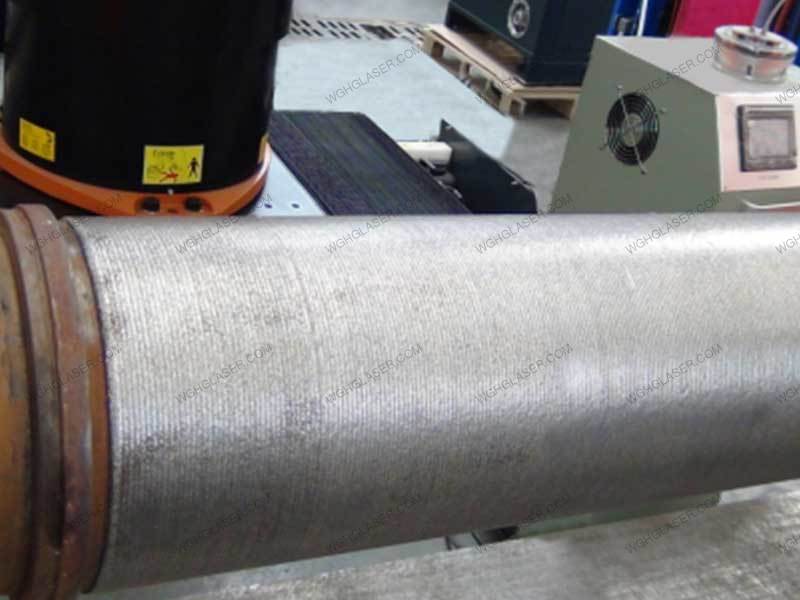

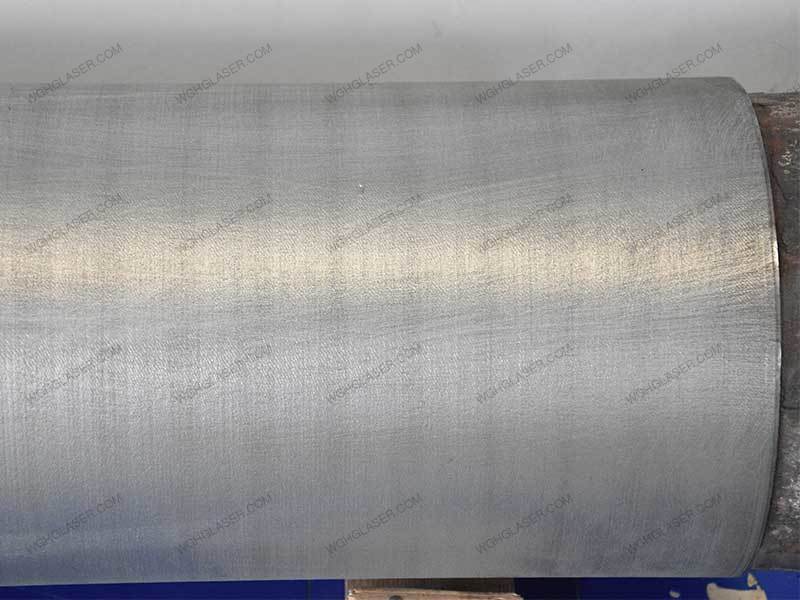

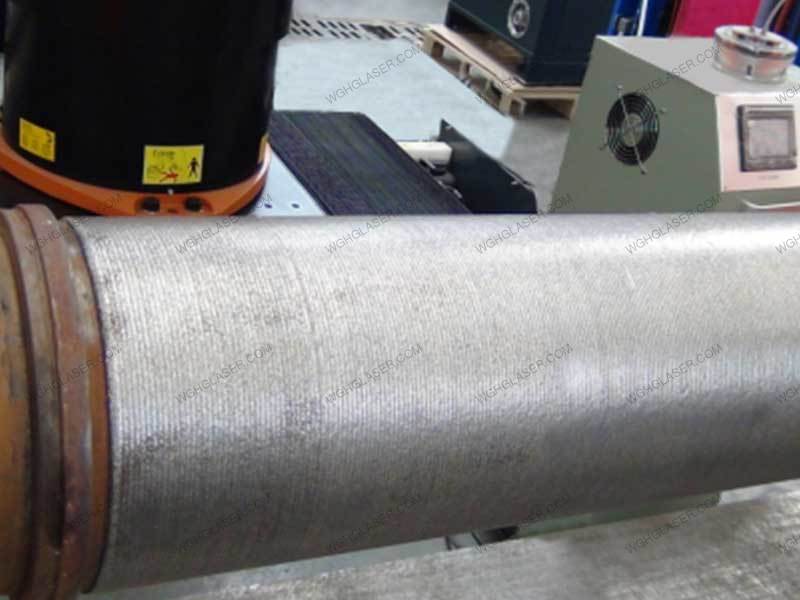

The cladding layer has high density without defects, flat surface, small machining amount, adjustable hardness HRC42 ~ 60 and corrosion resistance.

Structure Type

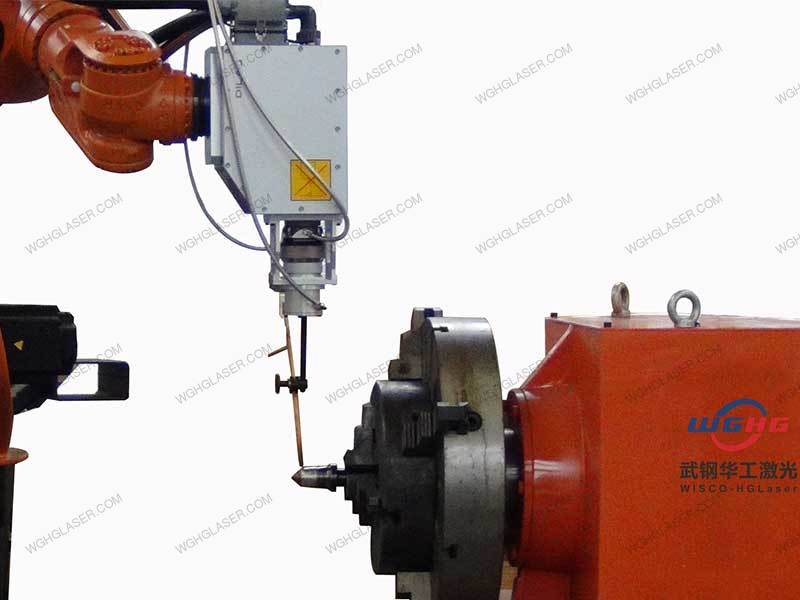

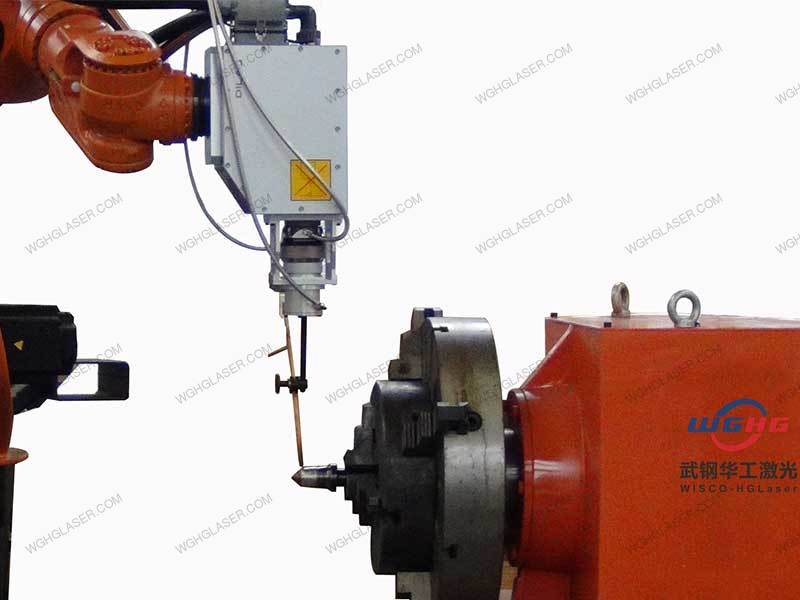

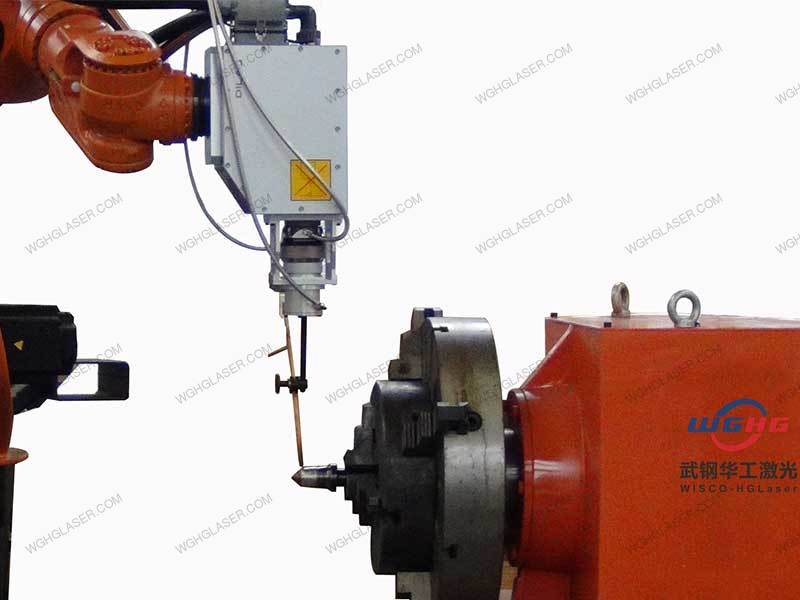

High speed laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Laser cladding equipment for hydraulic cylinder of coal machine

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

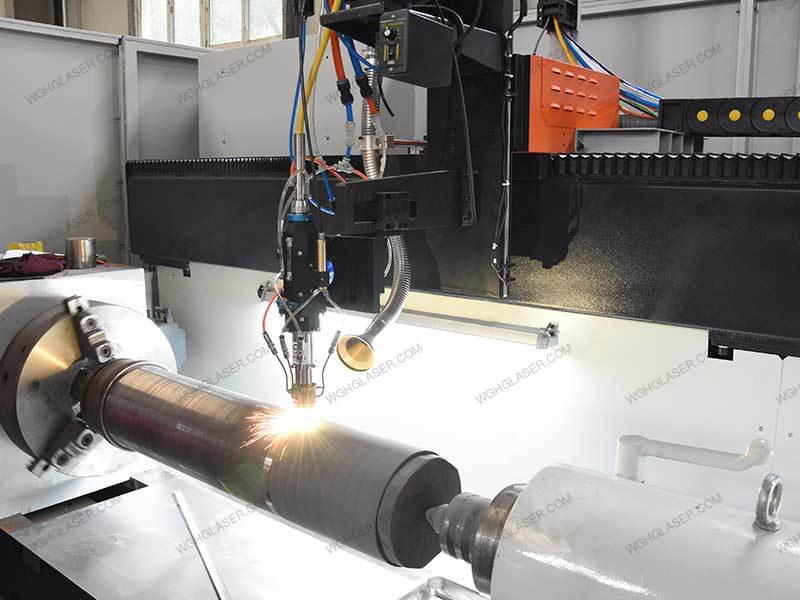

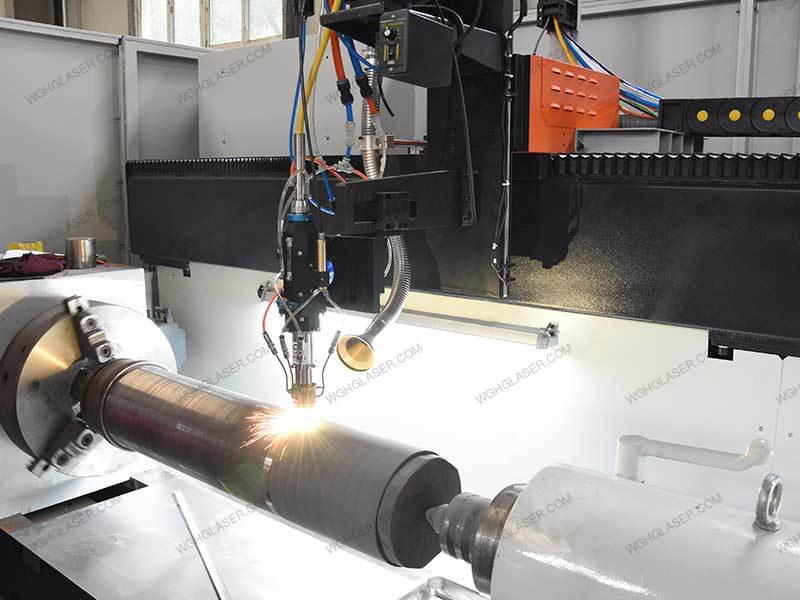

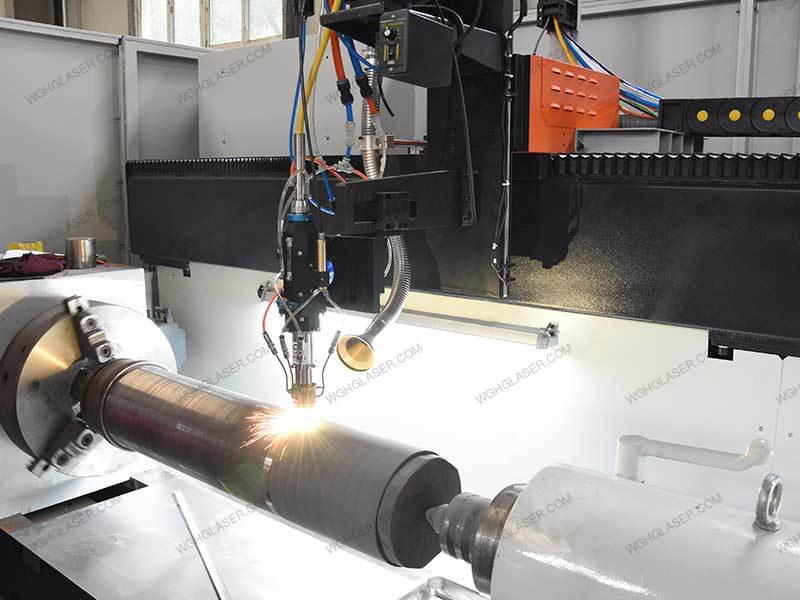

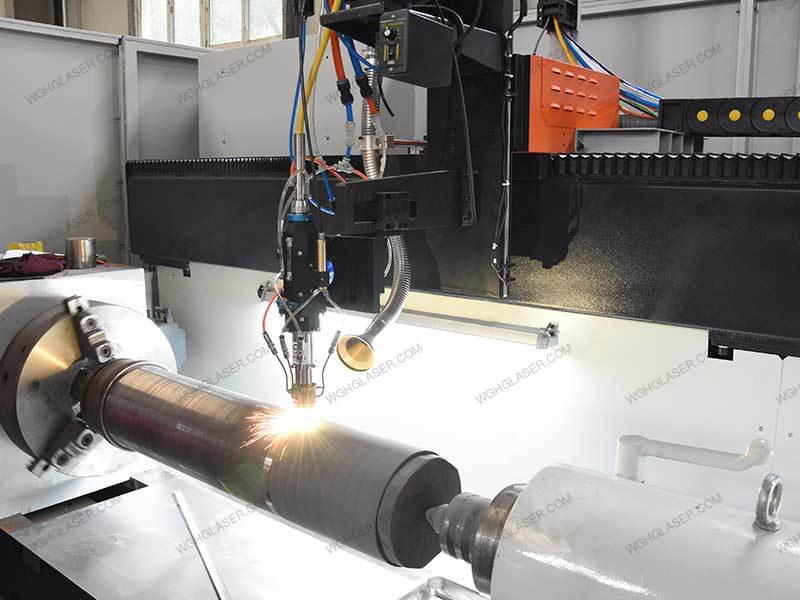

High-speed laser cladding for coal machine hydraulic cylinder

High-speed laser cladding for coal machine hydraulic cylinder

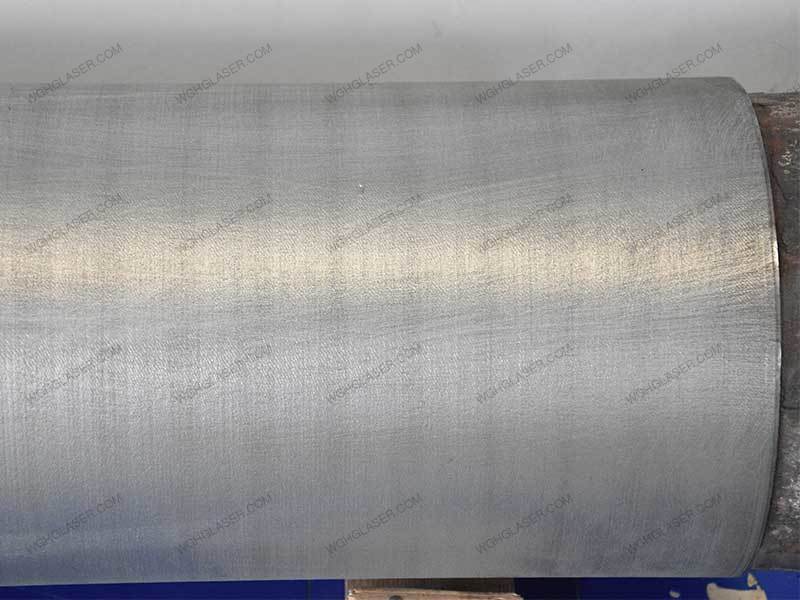

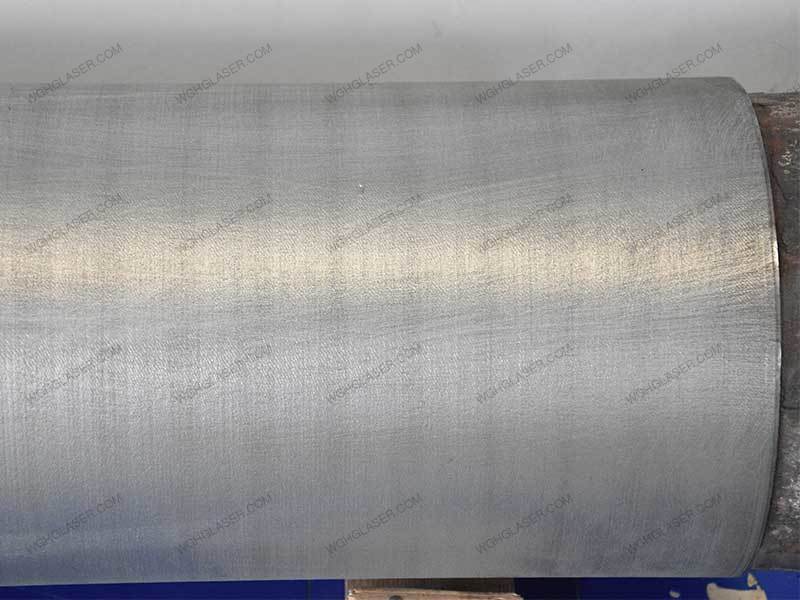

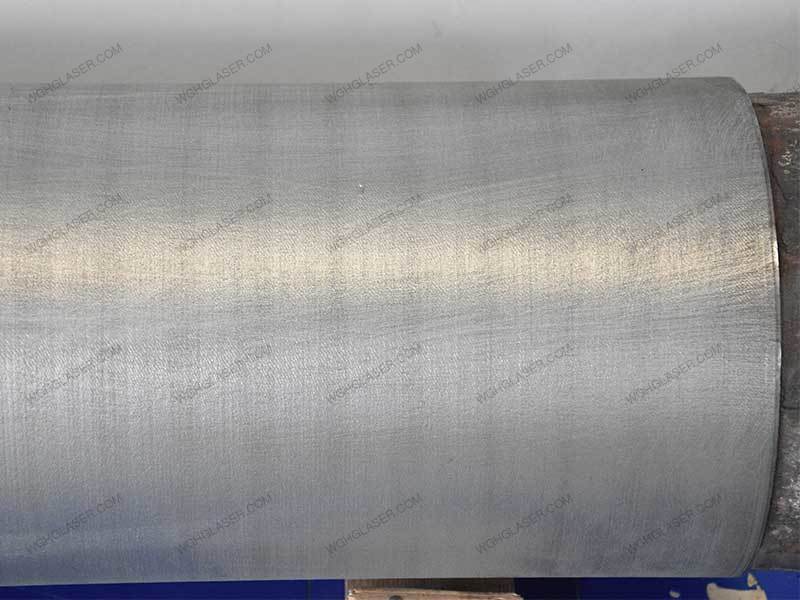

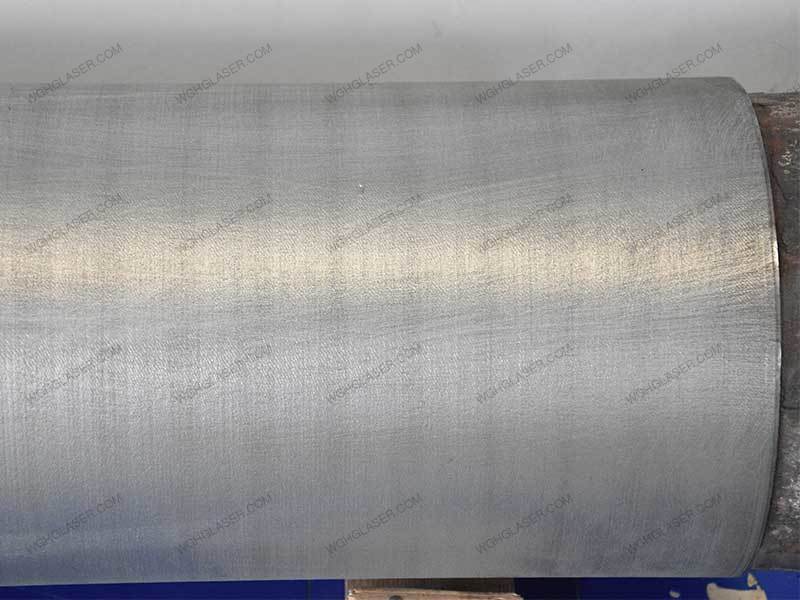

High speed laser cladding surface for hydraulic support

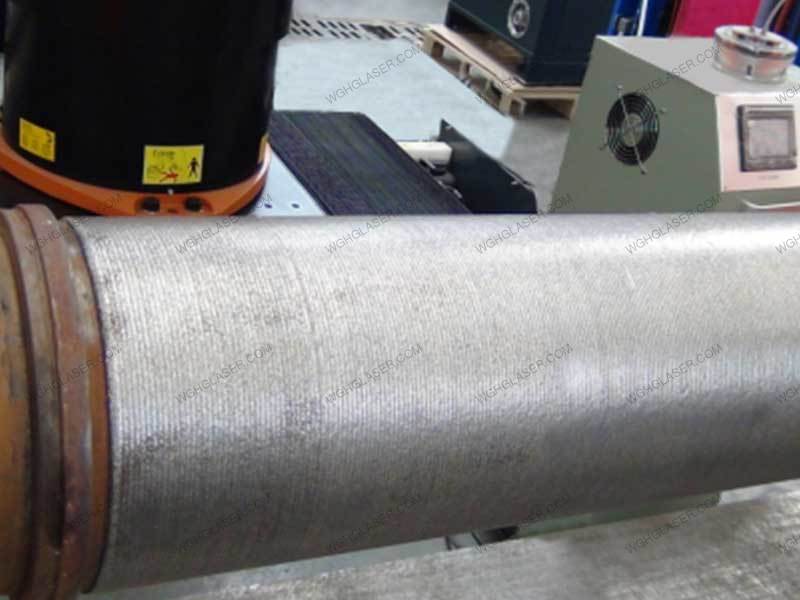

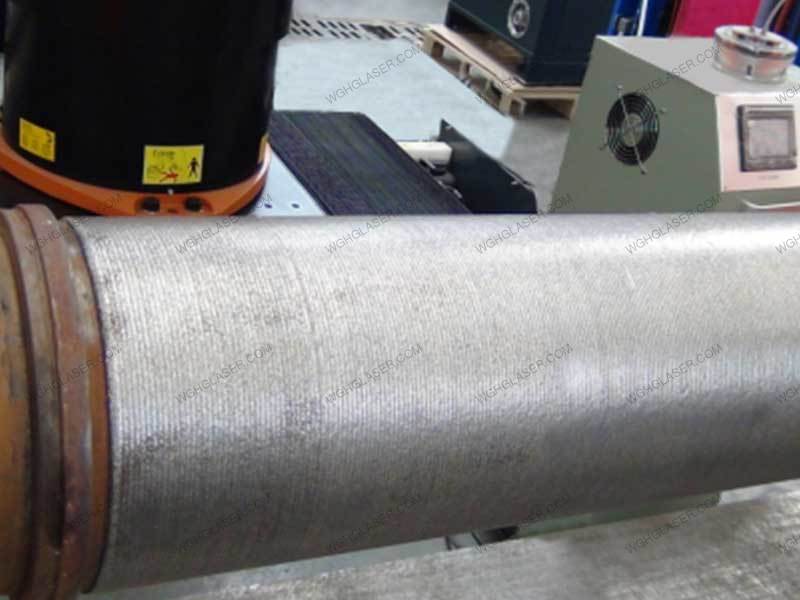

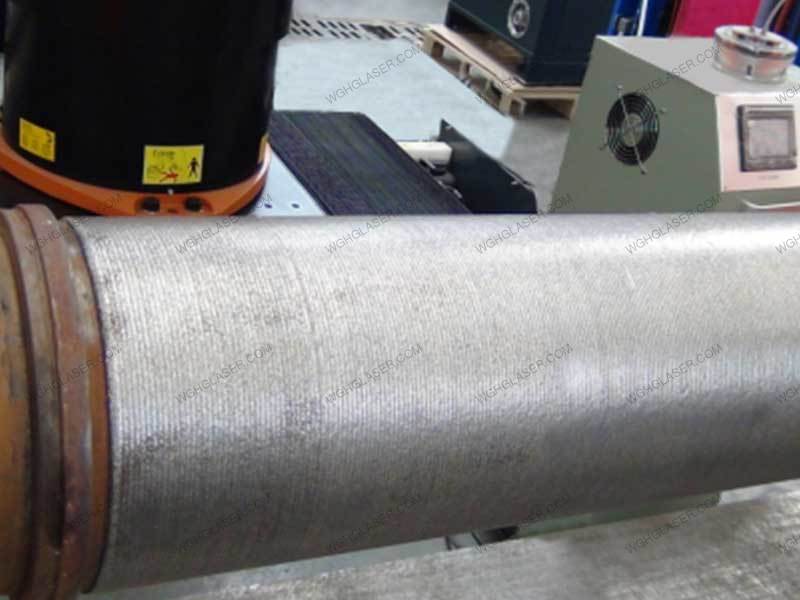

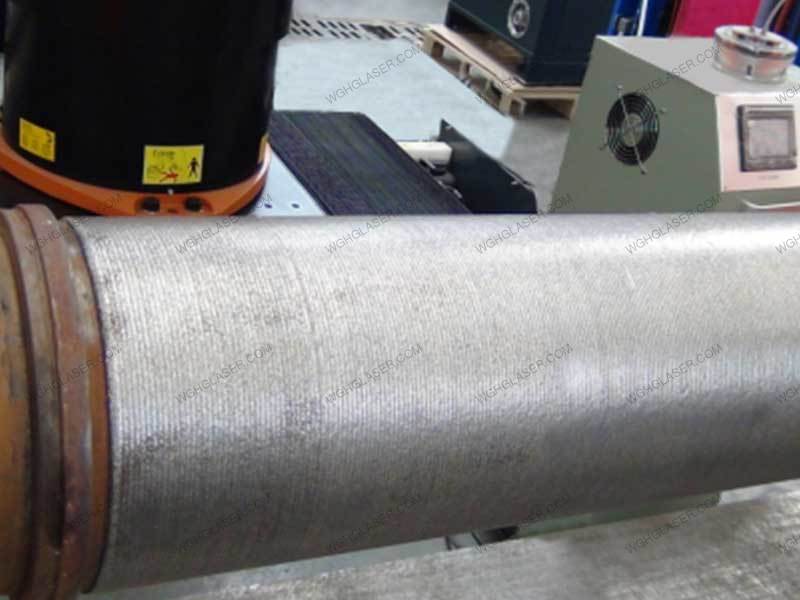

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface with wide spot for hydraulic support

Laser cladding for Pick

Laser cladding for coal machine hydraulic cylinder

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface of round spot for hydraulic support

Laser cladding for hydraulic cylinder inner hole

Laser cladding

Laser cladding

Application industry

Repair and remanufacturing of oil cylinder, reducer, crusher, scraper, hydraulic support and other coal machine parts.

Categories

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JKR coal machine hydraulic cylinder laser cladding equipment

Product Description: Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

-

Application industry: Coal machine industry

Applicable materials: low carbon steel, medium carbon steel, high carbon steel, etc.

Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

WISCO-HGlaser has developed and designed a special laser cladding equipment for Laser Cladding Hydraulic Cylinder in the mining machinery industry, and is capable of forming batch processing equipment in this industry, which can prepare high-performance alloy surface on the metal substrate of parts and components to significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other properties of the workpiece surface. It not only reduces the cost, but improves the service life, which is more beneficial to environmental protection.

Advantages Introduction:

High cost performance ratio

Precisely controllable

Stable and reliable

High density of cladding layer

The whole machine is simple in structure, low in comprehensive maintenance cost, high in efficiency and high in reliability.

Accurate and controllable laser position, controllable temperature feedback, controllable processing process and high efficiency.

Modular design, real-time data monitoring, low failure rate, close to maintenance free.

The cladding layer has high density without defects, flat surface, small machining amount, adjustable hardness HRC42 ~ 60 and corrosion resistance.

Structure Type

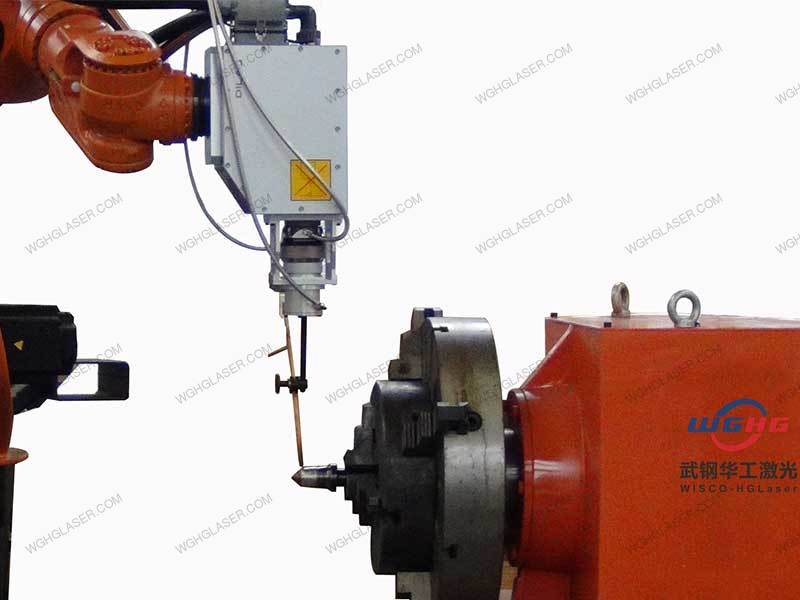

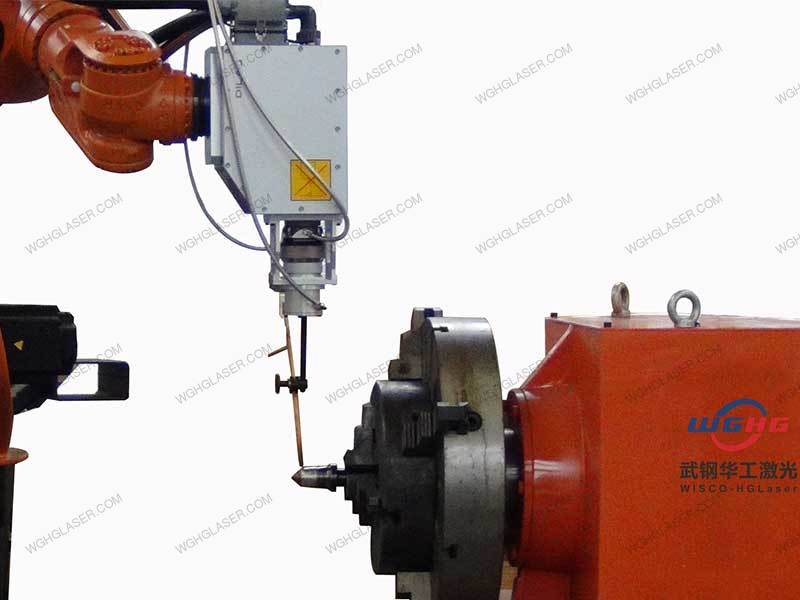

High speed laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Laser cladding equipment for hydraulic cylinder of coal machine

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

High-speed laser cladding for coal machine hydraulic cylinder

High-speed laser cladding for coal machine hydraulic cylinder

High speed laser cladding surface for hydraulic support

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface with wide spot for hydraulic support

Laser cladding for Pick

Laser cladding for coal machine hydraulic cylinder

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface of round spot for hydraulic support

Laser cladding for hydraulic cylinder inner hole

Laser cladding

Laser cladding

Application industry

Repair and remanufacturing of oil cylinder, reducer, crusher, scraper, hydraulic support and other coal machine parts.

Categories

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JKR coal machine hydraulic cylinder laser cladding equipment

Product Description: Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

-

Application industry: Coal machine industry

Applicable materials: low carbon steel, medium carbon steel, high carbon steel, etc.

Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

WISCO-HGlaser has developed and designed a special laser cladding equipment for Laser Cladding Hydraulic Cylinder in the mining machinery industry, and is capable of forming batch processing equipment in this industry, which can prepare high-performance alloy surface on the metal substrate of parts and components to significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other properties of the workpiece surface. It not only reduces the cost, but improves the service life, which is more beneficial to environmental protection.

Advantages Introduction:

High cost performance ratio

Precisely controllable

Stable and reliable

High density of cladding layer

The whole machine is simple in structure, low in comprehensive maintenance cost, high in efficiency and high in reliability.

Accurate and controllable laser position, controllable temperature feedback, controllable processing process and high efficiency.

Modular design, real-time data monitoring, low failure rate, close to maintenance free.

The cladding layer has high density without defects, flat surface, small machining amount, adjustable hardness HRC42 ~ 60 and corrosion resistance.

Structure Type

High speed laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Laser cladding equipment for hydraulic cylinder of coal machine

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

High-speed laser cladding for coal machine hydraulic cylinder

High-speed laser cladding for coal machine hydraulic cylinder

High speed laser cladding surface for hydraulic support

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface with wide spot for hydraulic support

Laser cladding for Pick

Laser cladding for coal machine hydraulic cylinder

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface of round spot for hydraulic support

Laser cladding for hydraulic cylinder inner hole

Laser cladding

Laser cladding

Application industry

Repair and remanufacturing of oil cylinder, reducer, crusher, scraper, hydraulic support and other coal machine parts.

Categories

Laser Cleaning Equipment Series

JKR coal machine hydraulic cylinder laser cladding equipment

Product Description: Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

-

Application industry: Coal machine industry

Applicable materials: low carbon steel, medium carbon steel, high carbon steel, etc.

Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

WISCO-HGlaser has developed and designed a special laser cladding equipment for Laser Cladding Hydraulic Cylinder in the mining machinery industry, and is capable of forming batch processing equipment in this industry, which can prepare high-performance alloy surface on the metal substrate of parts and components to significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other properties of the workpiece surface. It not only reduces the cost, but improves the service life, which is more beneficial to environmental protection.

Advantages Introduction:

High cost performance ratio

Precisely controllable

Stable and reliable

High density of cladding layer

The whole machine is simple in structure, low in comprehensive maintenance cost, high in efficiency and high in reliability.

Accurate and controllable laser position, controllable temperature feedback, controllable processing process and high efficiency.

Modular design, real-time data monitoring, low failure rate, close to maintenance free.

The cladding layer has high density without defects, flat surface, small machining amount, adjustable hardness HRC42 ~ 60 and corrosion resistance.

Structure Type

High speed laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Laser cladding equipment for hydraulic cylinder of coal machine

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

High-speed laser cladding for coal machine hydraulic cylinder

High-speed laser cladding for coal machine hydraulic cylinder

High speed laser cladding surface for hydraulic support

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface with wide spot for hydraulic support

Laser cladding for Pick

Laser cladding for coal machine hydraulic cylinder

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface of round spot for hydraulic support

Laser cladding for hydraulic cylinder inner hole

Laser cladding

Laser cladding

Application industry

Repair and remanufacturing of oil cylinder, reducer, crusher, scraper, hydraulic support and other coal machine parts.

JKR coal machine hydraulic cylinder laser cladding equipment

Product Description: Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

-

Application industry: Coal machine industry

Applicable materials: low carbon steel, medium carbon steel, high carbon steel, etc.

Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

WISCO-HGlaser has developed and designed a special laser cladding equipment for Laser Cladding Hydraulic Cylinder in the mining machinery industry, and is capable of forming batch processing equipment in this industry, which can prepare high-performance alloy surface on the metal substrate of parts and components to significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other properties of the workpiece surface. It not only reduces the cost, but improves the service life, which is more beneficial to environmental protection.

Advantages Introduction:

High cost performance ratio

Precisely controllable

Stable and reliable

High density of cladding layer

The whole machine is simple in structure, low in comprehensive maintenance cost, high in efficiency and high in reliability.

Accurate and controllable laser position, controllable temperature feedback, controllable processing process and high efficiency.

Modular design, real-time data monitoring, low failure rate, close to maintenance free.

The cladding layer has high density without defects, flat surface, small machining amount, adjustable hardness HRC42 ~ 60 and corrosion resistance.

Structure Type

High speed laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Laser cladding equipment for hydraulic cylinder of coal machine

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

High-speed laser cladding for coal machine hydraulic cylinder

High-speed laser cladding for coal machine hydraulic cylinder

High speed laser cladding surface for hydraulic support

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface with wide spot for hydraulic support

Laser cladding for Pick

Laser cladding for coal machine hydraulic cylinder

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface of round spot for hydraulic support

Laser cladding for hydraulic cylinder inner hole

Laser cladding

Laser cladding

Application industry

Repair and remanufacturing of oil cylinder, reducer, crusher, scraper, hydraulic support and other coal machine parts.

JKR coal machine hydraulic cylinder laser cladding equipment

Product Description: Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

Application industry: Coal machine industry

Applicable materials: low carbon steel, medium carbon steel, high carbon steel, etc.

Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

WISCO-HGlaser has developed and designed a special laser cladding equipment for Laser Cladding Hydraulic Cylinder in the mining machinery industry, and is capable of forming batch processing equipment in this industry, which can prepare high-performance alloy surface on the metal substrate of parts and components to significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other properties of the workpiece surface. It not only reduces the cost, but improves the service life, which is more beneficial to environmental protection.

Advantages Introduction:

Structure Type

High speed laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Common laser cladding equipment for hydraulic cylinder of coal machine

Laser cladding equipment for hydraulic cylinder of coal machine

Technical Parameters

Sample Display

Application industry

Repair and remanufacturing of oil cylinder, reducer, crusher, scraper, hydraulic support and other coal machine parts.

Applicable materials: low carbon steel, medium carbon steel, high carbon steel, etc.

Advanced laser (power 3~15KW), supplemented by highly integrated equipment for three-axis/four-axis CNC machine tools. It is special equipment for laser re-manufacturing and repair processing of coal machinery and engineering machinery industry parts, and it is efficient equipment suitable for mass production. Meet the needs of advanced manufacturing processes such as laser cladding/re-manufacturing and laser alloying of metal workpiece surfaces.

WISCO-HGlaser has developed and designed a special laser cladding equipment for Laser Cladding Hydraulic Cylinder in the mining machinery industry, and is capable of forming batch processing equipment in this industry, which can prepare high-performance alloy surface on the metal substrate of parts and components to significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant and other properties of the workpiece surface. It not only reduces the cost, but improves the service life, which is more beneficial to environmental protection.

Advantages Introduction:

| High cost performance ratio | Precisely controllable | Stable and reliable | High density of cladding layer |

| The whole machine is simple in structure, low in comprehensive maintenance cost, high in efficiency and high in reliability. | Accurate and controllable laser position, controllable temperature feedback, controllable processing process and high efficiency. | Modular design, real-time data monitoring, low failure rate, close to maintenance free. | The cladding layer has high density without defects, flat surface, small machining amount, adjustable hardness HRC42 ~ 60 and corrosion resistance. |

Structure Type

High speed laser cladding equipment for hydraulic cylinder of coal machine

| Content | Parameters |

| Laser | 0.5-20kW, fiber, semiconductor, disc, etc. |

| Robot | Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc. |

| Laser Processing Head | 0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder |

| Powder Feeder | Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units |

| Cooling-water Machine | Single temperature, dual temperature, cooling capacity according to laser selection |

| Optional Accessories | Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc. |

| Input Voltage | 360-480V Three-Phase Five-Wire System @50-60Hz |

Sample Display

High-speed laser cladding for coal machine hydraulic cylinder

High-speed laser cladding for coal machine hydraulic cylinder

High speed laser cladding surface for hydraulic support

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface with wide spot for hydraulic support

Laser cladding for Pick

Laser cladding for coal machine hydraulic cylinder

Laser cladding for coal machine hydraulic cylinder

Laser cladding surface of round spot for hydraulic support

Laser cladding for hydraulic cylinder inner hole

Laser cladding

Laser cladding

Application industry

Repair and remanufacturing of oil cylinder, reducer, crusher, scraper, hydraulic support and other coal machine parts.