Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

RRWL Laser Cladding Equipment

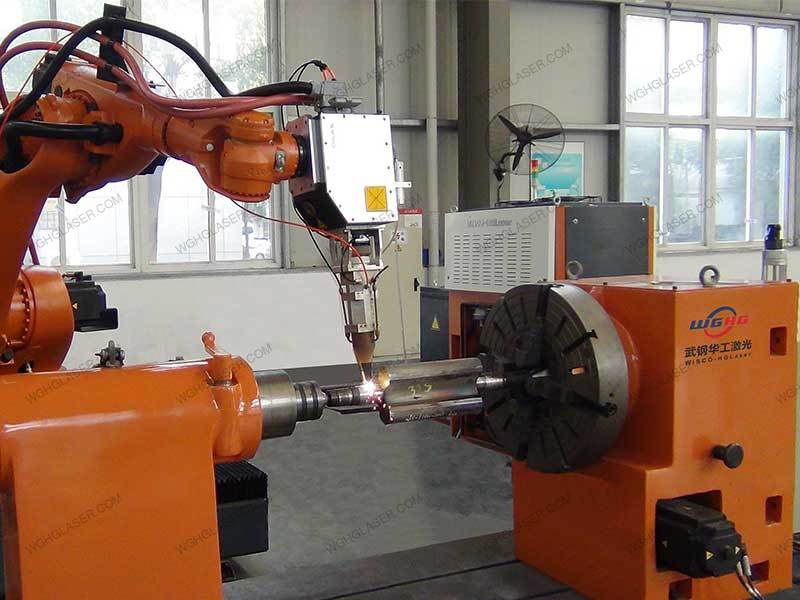

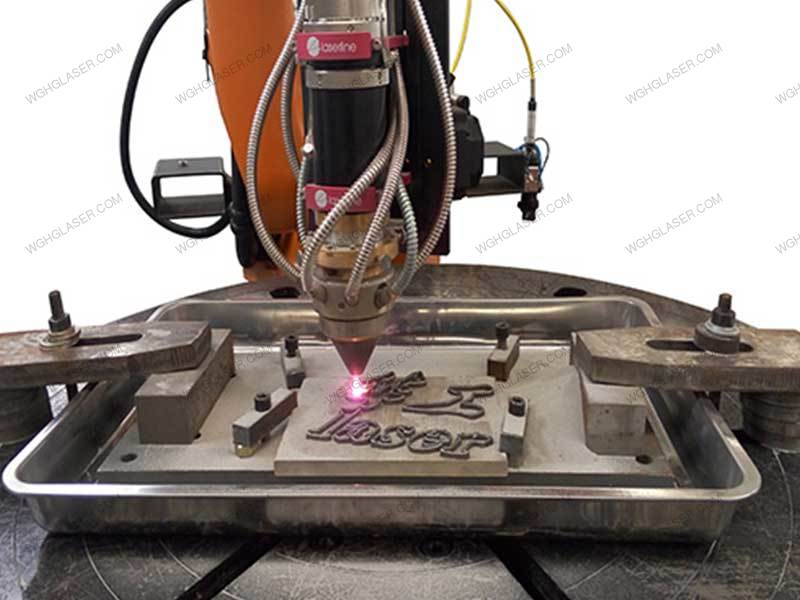

Product Description: Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole)), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

-

Application industry: Application industry: metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Applicable materials: metals (ferrous metals such as steel and cast iron, and non-ferrous metals such as aluminum, copper, and titanium).

Laser Cladding Equipment Laser Cladding Machines Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Advantages Introduction: With high-energy laser, stable and reliable, multi-axis linkage flexibility, good openness of function.

Structure Type

Multi-functional universal structure: general-purpose equipment for laser surface strengthening and re-manufacturing of metallurgy, automotive molds, mine machinery, coal machinery, petrochemical machinery, generator sets and other parts.

Mold reinforcement structure: meet the needs of advanced surface manufacturing processes such as laser quenching and repair of large and small molds.

Field service structure: Surface strengthening and re-manufacturing on-site processing of large workpieces and difficult-to-remove parts. The equipment has the advantages of convenient vehicle movement and quick installation on site.

Closed structure: The processing area is fully enclosed, safe and more reliable, and external visual monitoring.

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for rolling mill archway

Laser repairing for blast furnace tuyere copper nozzle

Laser cladding for spherical

Laser cladding for gate valve stem

Laser cladding for gate valve stem

Laser cladding for furnace bottom roller

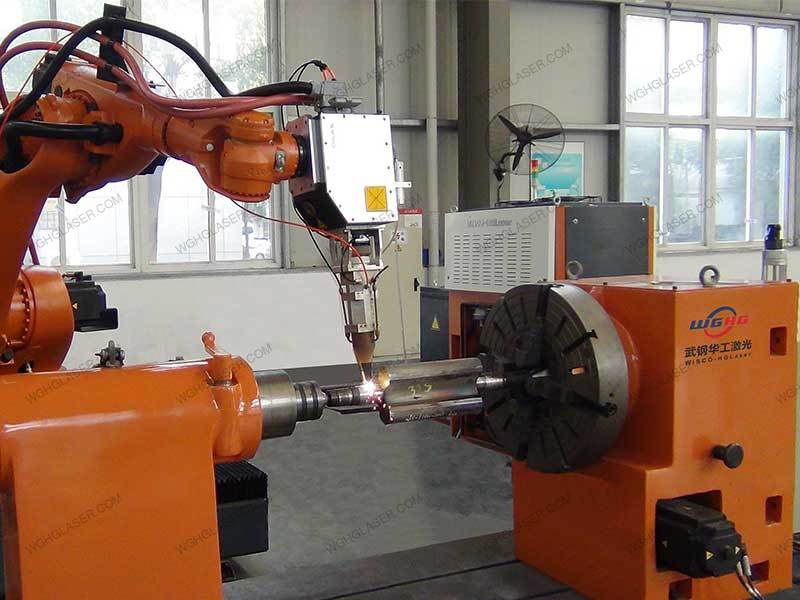

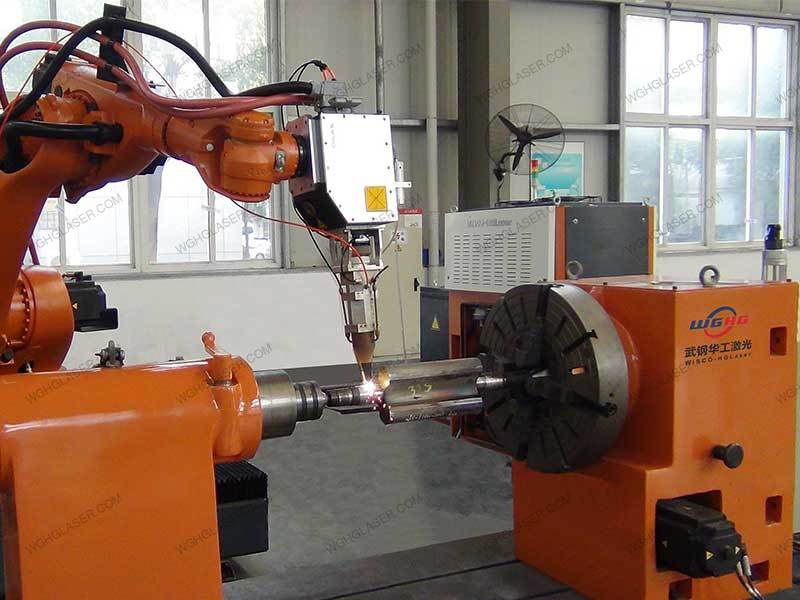

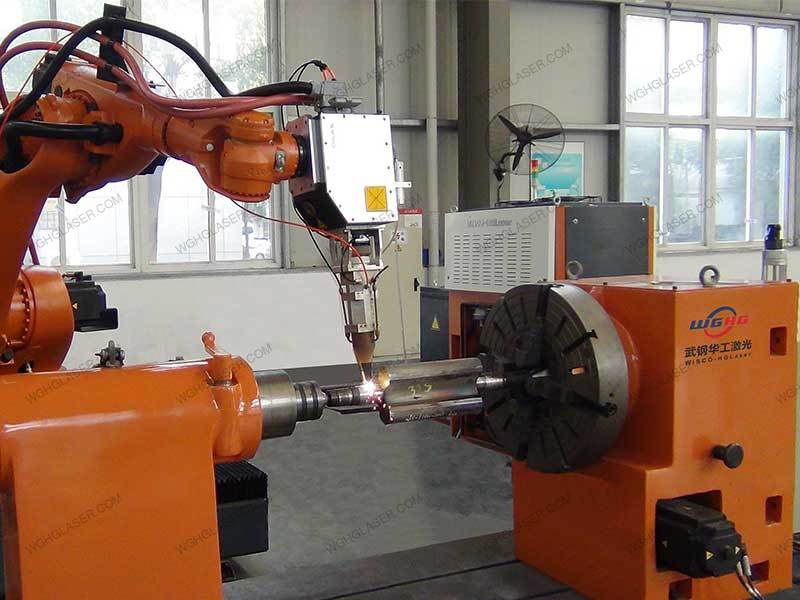

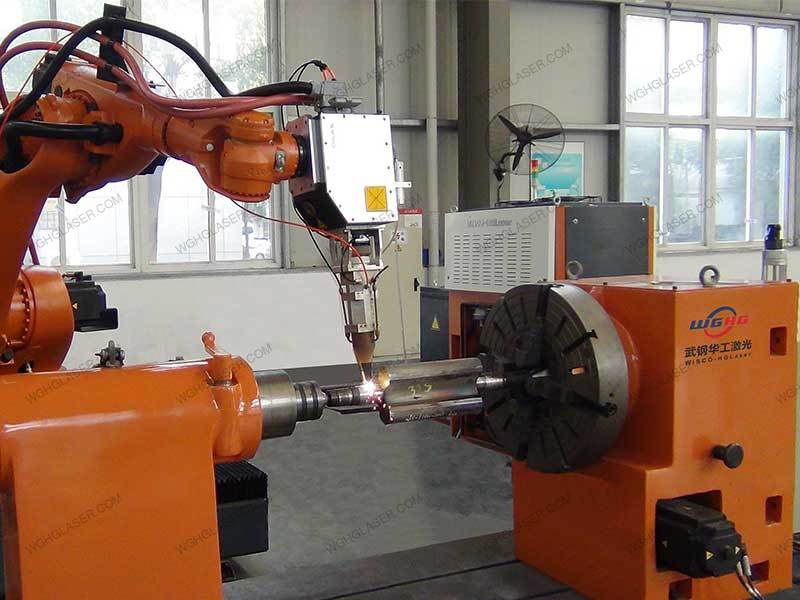

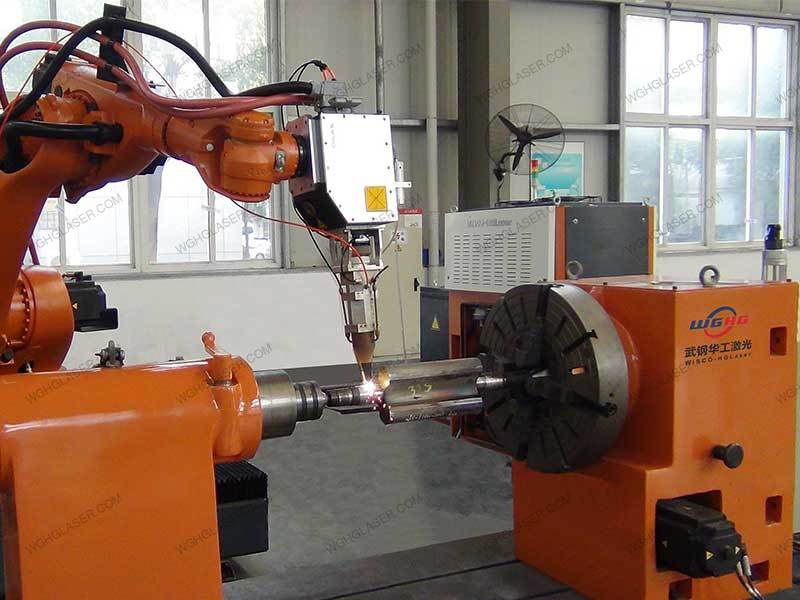

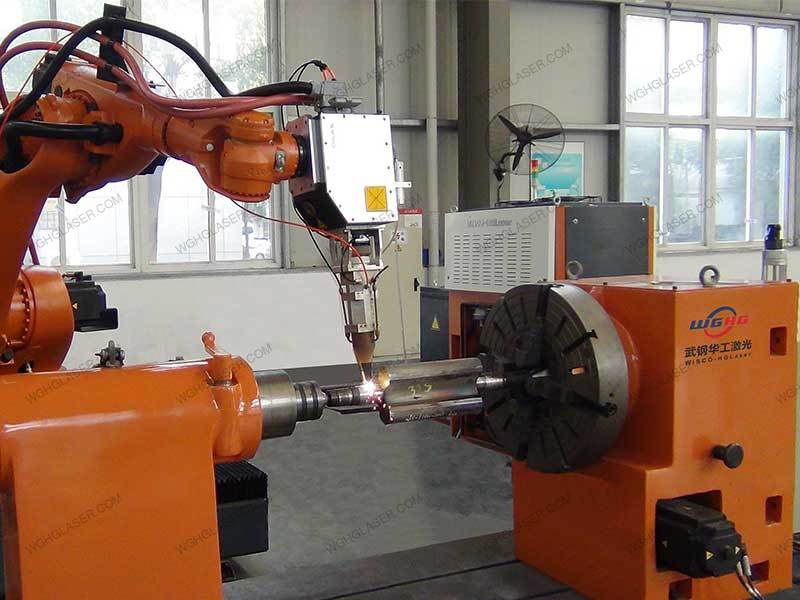

Laser quenching for Long axis

Laser quenching for hammer seat

Laser Quenching for Propeller Oil Rod

Laser quenching for Anchor sprocket

Laser alloying for Spiral rod

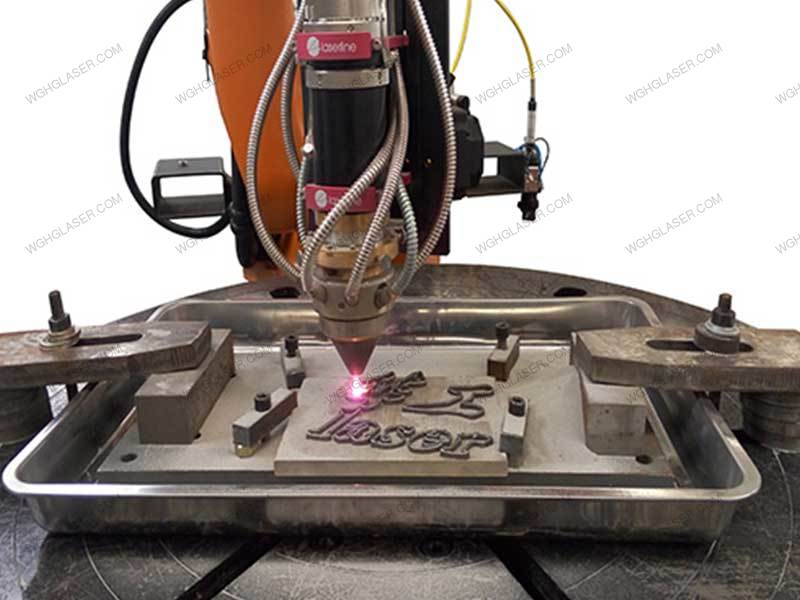

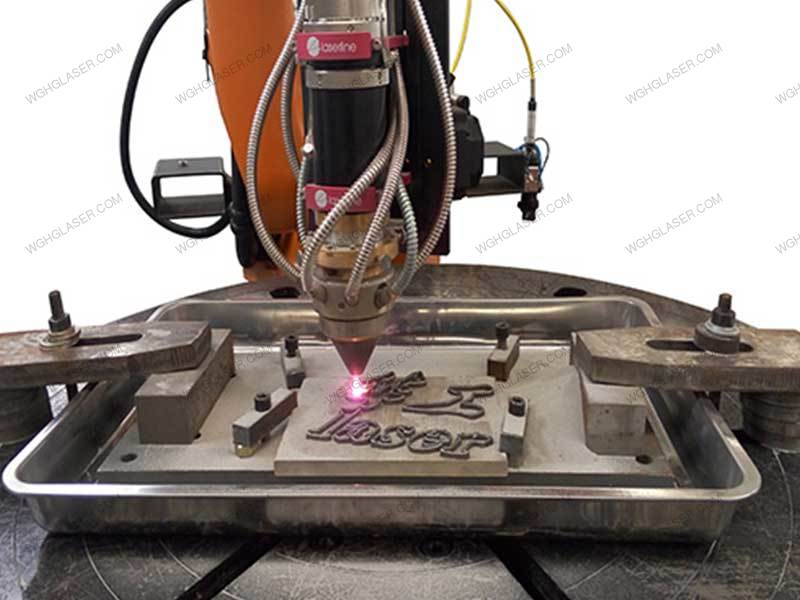

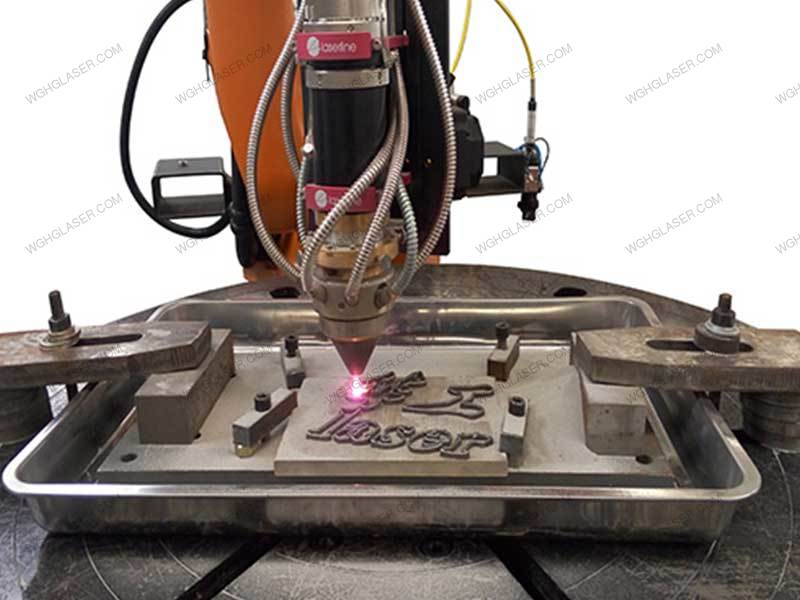

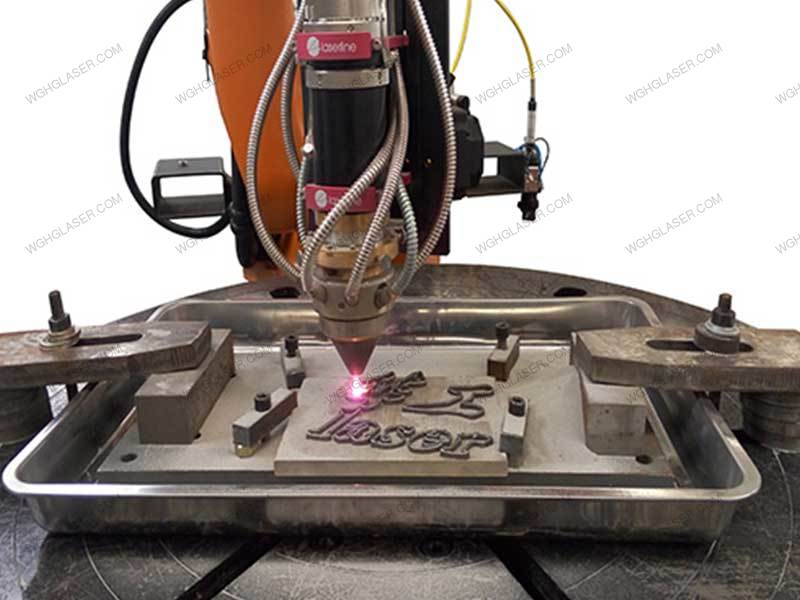

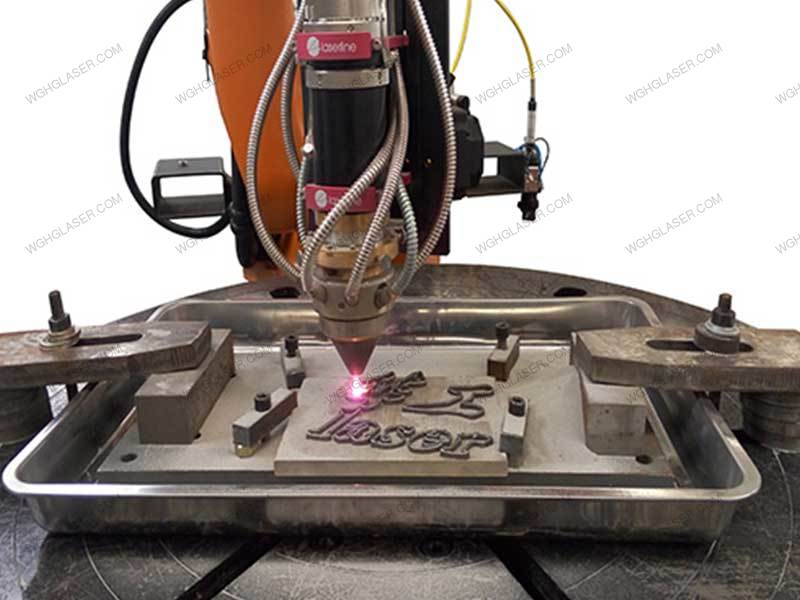

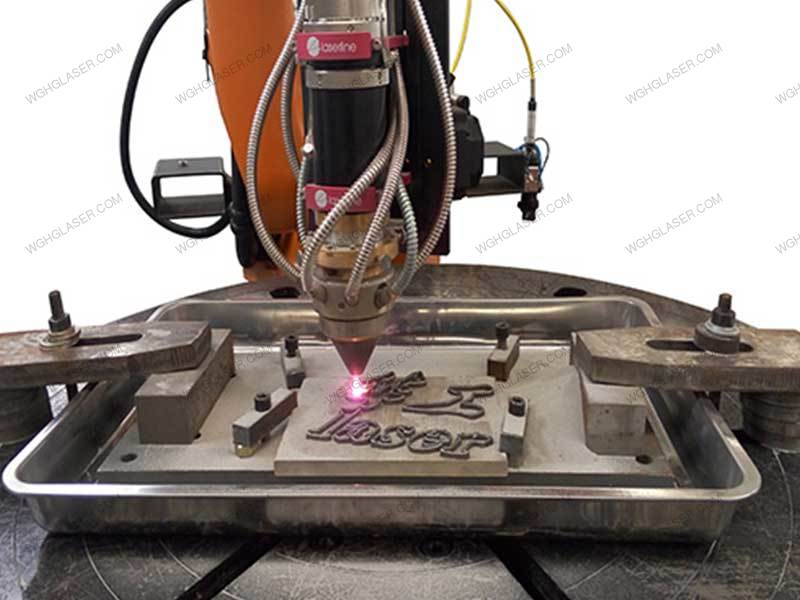

Laser 3D Printing

Application industry

Metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Categories

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

RRWL Laser Cladding Equipment

Product Description: Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole)), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

-

Application industry: Application industry: metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Applicable materials: metals (ferrous metals such as steel and cast iron, and non-ferrous metals such as aluminum, copper, and titanium).

Laser Cladding Equipment Laser Cladding Machines Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Advantages Introduction: With high-energy laser, stable and reliable, multi-axis linkage flexibility, good openness of function.

Structure Type

Multi-functional universal structure: general-purpose equipment for laser surface strengthening and re-manufacturing of metallurgy, automotive molds, mine machinery, coal machinery, petrochemical machinery, generator sets and other parts.

Mold reinforcement structure: meet the needs of advanced surface manufacturing processes such as laser quenching and repair of large and small molds.

Field service structure: Surface strengthening and re-manufacturing on-site processing of large workpieces and difficult-to-remove parts. The equipment has the advantages of convenient vehicle movement and quick installation on site.

Closed structure: The processing area is fully enclosed, safe and more reliable, and external visual monitoring.

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for rolling mill archway

Laser repairing for blast furnace tuyere copper nozzle

Laser cladding for spherical

Laser cladding for gate valve stem

Laser cladding for gate valve stem

Laser cladding for furnace bottom roller

Laser quenching for Long axis

Laser quenching for hammer seat

Laser Quenching for Propeller Oil Rod

Laser quenching for Anchor sprocket

Laser alloying for Spiral rod

Laser 3D Printing

Application industry

Metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Categories

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

RRWL Laser Cladding Equipment

Product Description: Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole)), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

-

Application industry: Application industry: metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Applicable materials: metals (ferrous metals such as steel and cast iron, and non-ferrous metals such as aluminum, copper, and titanium).

Laser Cladding Equipment Laser Cladding Machines Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Advantages Introduction: With high-energy laser, stable and reliable, multi-axis linkage flexibility, good openness of function.

Structure Type

Multi-functional universal structure: general-purpose equipment for laser surface strengthening and re-manufacturing of metallurgy, automotive molds, mine machinery, coal machinery, petrochemical machinery, generator sets and other parts.

Mold reinforcement structure: meet the needs of advanced surface manufacturing processes such as laser quenching and repair of large and small molds.

Field service structure: Surface strengthening and re-manufacturing on-site processing of large workpieces and difficult-to-remove parts. The equipment has the advantages of convenient vehicle movement and quick installation on site.

Closed structure: The processing area is fully enclosed, safe and more reliable, and external visual monitoring.

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for rolling mill archway

Laser repairing for blast furnace tuyere copper nozzle

Laser cladding for spherical

Laser cladding for gate valve stem

Laser cladding for gate valve stem

Laser cladding for furnace bottom roller

Laser quenching for Long axis

Laser quenching for hammer seat

Laser Quenching for Propeller Oil Rod

Laser quenching for Anchor sprocket

Laser alloying for Spiral rod

Laser 3D Printing

Application industry

Metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Categories

Laser Cleaning Equipment Series

RRWL Laser Cladding Equipment

Product Description: Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole)), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

-

Application industry: Application industry: metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Applicable materials: metals (ferrous metals such as steel and cast iron, and non-ferrous metals such as aluminum, copper, and titanium).

Laser Cladding Equipment Laser Cladding Machines Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Advantages Introduction: With high-energy laser, stable and reliable, multi-axis linkage flexibility, good openness of function.

Structure Type

Multi-functional universal structure: general-purpose equipment for laser surface strengthening and re-manufacturing of metallurgy, automotive molds, mine machinery, coal machinery, petrochemical machinery, generator sets and other parts.

Mold reinforcement structure: meet the needs of advanced surface manufacturing processes such as laser quenching and repair of large and small molds.

Field service structure: Surface strengthening and re-manufacturing on-site processing of large workpieces and difficult-to-remove parts. The equipment has the advantages of convenient vehicle movement and quick installation on site.

Closed structure: The processing area is fully enclosed, safe and more reliable, and external visual monitoring.

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for rolling mill archway

Laser repairing for blast furnace tuyere copper nozzle

Laser cladding for spherical

Laser cladding for gate valve stem

Laser cladding for gate valve stem

Laser cladding for furnace bottom roller

Laser quenching for Long axis

Laser quenching for hammer seat

Laser Quenching for Propeller Oil Rod

Laser quenching for Anchor sprocket

Laser alloying for Spiral rod

Laser 3D Printing

Application industry

Metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

RRWL Laser Cladding Equipment

Product Description: Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole)), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

-

Application industry: Application industry: metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Applicable materials: metals (ferrous metals such as steel and cast iron, and non-ferrous metals such as aluminum, copper, and titanium).

Laser Cladding Equipment Laser Cladding Machines Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Advantages Introduction: With high-energy laser, stable and reliable, multi-axis linkage flexibility, good openness of function.

Structure Type

Multi-functional universal structure: general-purpose equipment for laser surface strengthening and re-manufacturing of metallurgy, automotive molds, mine machinery, coal machinery, petrochemical machinery, generator sets and other parts.

Mold reinforcement structure: meet the needs of advanced surface manufacturing processes such as laser quenching and repair of large and small molds.

Field service structure: Surface strengthening and re-manufacturing on-site processing of large workpieces and difficult-to-remove parts. The equipment has the advantages of convenient vehicle movement and quick installation on site.

Closed structure: The processing area is fully enclosed, safe and more reliable, and external visual monitoring.

Technical Parameters

Content

Parameters

Laser

0.5-20kW, fiber, semiconductor, disc, etc.

Robot

Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc.

Laser Processing Head

0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder

Powder Feeder

Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units

Cooling-water Machine

Single temperature, dual temperature, cooling capacity according to laser selection

Optional Accessories

Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc.

Input Voltage

360-480V Three-Phase Five-Wire System @50-60Hz

Sample Display

Laser repairing for rolling mill archway

Laser repairing for blast furnace tuyere copper nozzle

Laser cladding for spherical

Laser cladding for gate valve stem

Laser cladding for gate valve stem

Laser cladding for furnace bottom roller

Laser quenching for Long axis

Laser quenching for hammer seat

Laser Quenching for Propeller Oil Rod

Laser quenching for Anchor sprocket

Laser alloying for Spiral rod

Laser 3D Printing

Application industry

Metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

RRWL Laser Cladding Equipment

Product Description: Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole)), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Application industry: Application industry: metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Applicable materials: metals (ferrous metals such as steel and cast iron, and non-ferrous metals such as aluminum, copper, and titanium).

Laser Cladding Equipment Laser Cladding Machines Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Advantages Introduction: With high-energy laser, stable and reliable, multi-axis linkage flexibility, good openness of function.

Structure Type

Multi-functional universal structure: general-purpose equipment for laser surface strengthening and re-manufacturing of metallurgy, automotive molds, mine machinery, coal machinery, petrochemical machinery, generator sets and other parts.

Mold reinforcement structure: meet the needs of advanced surface manufacturing processes such as laser quenching and repair of large and small molds.

Field service structure: Surface strengthening and re-manufacturing on-site processing of large workpieces and difficult-to-remove parts. The equipment has the advantages of convenient vehicle movement and quick installation on site.

Closed structure: The processing area is fully enclosed, safe and more reliable, and external visual monitoring.

Technical Parameters

Sample Display

Application industry

Metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.

Applicable materials: metals (ferrous metals such as steel and cast iron, and non-ferrous metals such as aluminum, copper, and titanium).

Laser Cladding Equipment Laser Cladding Machines Advanced laser, six-axis robot and control system, multi-axis linkage flexible processing system to meet the surface of metal workpiece surface with laser quenching, laser alloying, laser cladding / re-manufacturing(Ultra high speed laser cladding、Conventional laser cladding、Wide spot laser cladding、Laser cladding of inner hole), laser additive manufacturing (laser 3D printing) and other advanced manufacturing process requirements.

Advantages Introduction: With high-energy laser, stable and reliable, multi-axis linkage flexibility, good openness of function.

Structure Type

Multi-functional universal structure: general-purpose equipment for laser surface strengthening and re-manufacturing of metallurgy, automotive molds, mine machinery, coal machinery, petrochemical machinery, generator sets and other parts.

Mold reinforcement structure: meet the needs of advanced surface manufacturing processes such as laser quenching and repair of large and small molds.

Field service structure: Surface strengthening and re-manufacturing on-site processing of large workpieces and difficult-to-remove parts. The equipment has the advantages of convenient vehicle movement and quick installation on site.

Closed structure: The processing area is fully enclosed, safe and more reliable, and external visual monitoring.

Technical Parameters

| Content | Parameters |

| Laser | 0.5-20kW, fiber, semiconductor, disc, etc. |

| Robot | Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc. |

| Laser Processing Head | 0.8-50mm round, square spot, size can be customized, coaxial, paraxonic powder feeder |

| Powder Feeder | Airborne, gravity conveying, powder feeding accuracy ≤±2%, powder feeding amount 10-150 g/min, single unit, double units |

| Cooling-water Machine | Single temperature, dual temperature, cooling capacity according to laser selection |

| Optional Accessories | Inner hole cladding head, temperature closed loop, on-line detection, distance detection, offline programming, molten pool monitoring, etc. |

| Input Voltage | 360-480V Three-Phase Five-Wire System @50-60Hz |

Sample Display

Laser repairing for rolling mill archway

Laser repairing for blast furnace tuyere copper nozzle

Laser cladding for spherical

Laser cladding for gate valve stem

Laser cladding for gate valve stem

Laser cladding for furnace bottom roller

Laser quenching for Long axis

Laser quenching for hammer seat

Laser Quenching for Propeller Oil Rod

Laser quenching for Anchor sprocket

Laser alloying for Spiral rod

Laser 3D Printing

Application industry

Metallurgy, mold, machinery manufacturing, petrochemical, light industry, energy, transportation, automotive, hardware tools, military and other industries.