Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JGK83 small roll laser texturing equipment

Product Description: The system consists of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering.

-

Application industry: steel, aluminum, titanium, non-ferrous metals and other industries

Applicable materials: titanium, aluminum, stainless steel, carbon steel, etc.

Laser Texturing Equipment of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering. The laser disordered texturing technology is independently developed and has a number of technical patents. At present, the system can realize single head and double head according to the number of lasers and texturing heads, and can be configured according to customer requirements.

Advantages Introduction:

higher control accuracy

The equipment is simple to operate

controllable morphology

low operating costs

Higher system integration,and more reliable stability.

Visual operation, easy to operate

Laser texturing processing has good uniformity, high repeatability and controllable morphology.

No pollution, low energy consumption, low noise, low operating costs.

Technical Parameters:

CNC System

Siemens CNC system 828D/840D (It can be customized).

Processing Roll Range

Diameter: Φ50mm~630mm

Roll total length: 0.5-6 meters

Roller Index after Texturing

Surface roughness Ra=0.5~15μm

Axial Linear Density

3~100 points/mm

Radial Line Density

disordered, frequency adjustable, up to 100KHz

Micro Pit Diameter

50~90μm

Micro Pit bulge Hardness

HV≥800

Micro Pit bulge Height

2~25μm

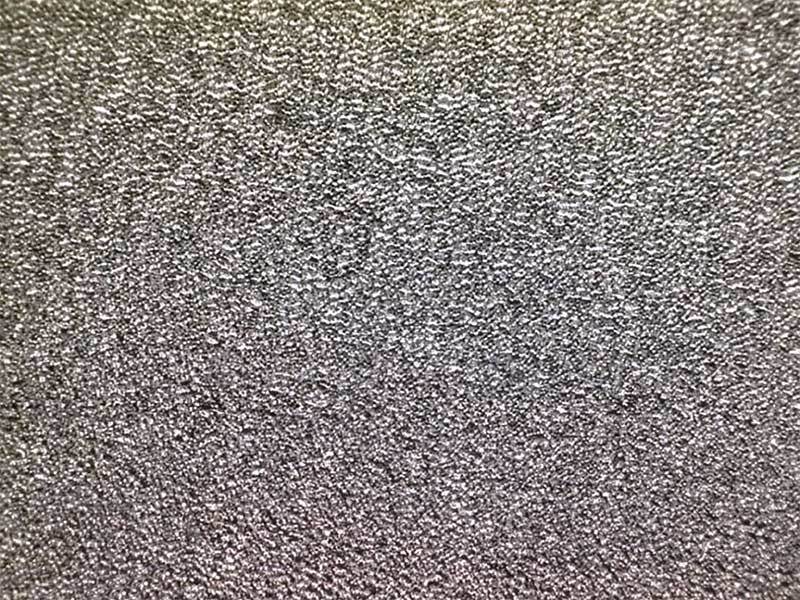

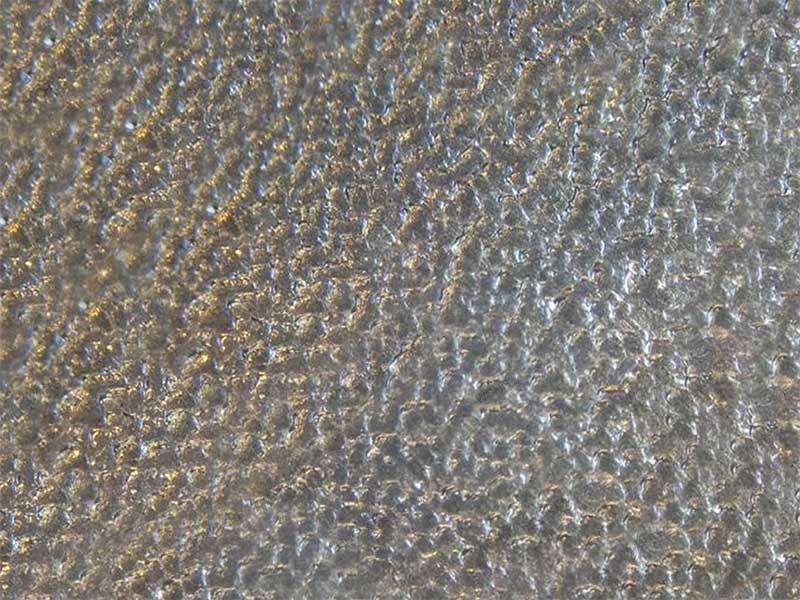

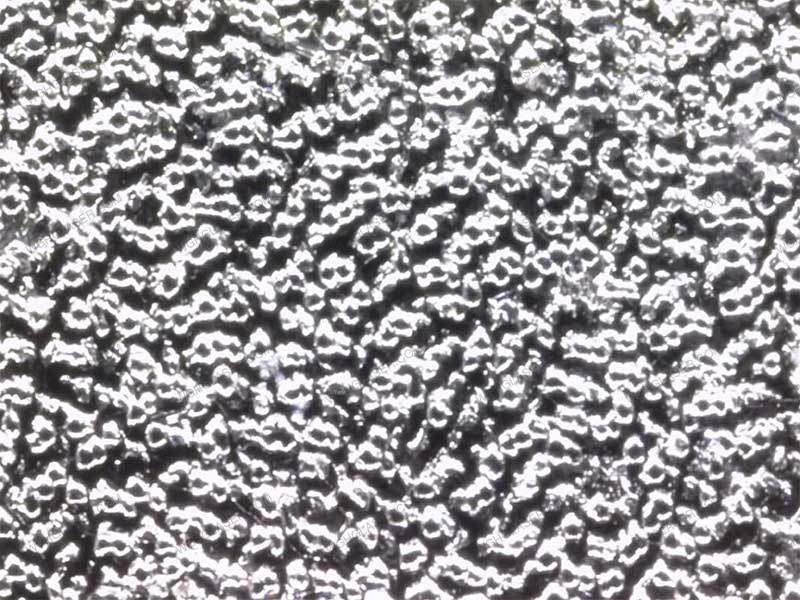

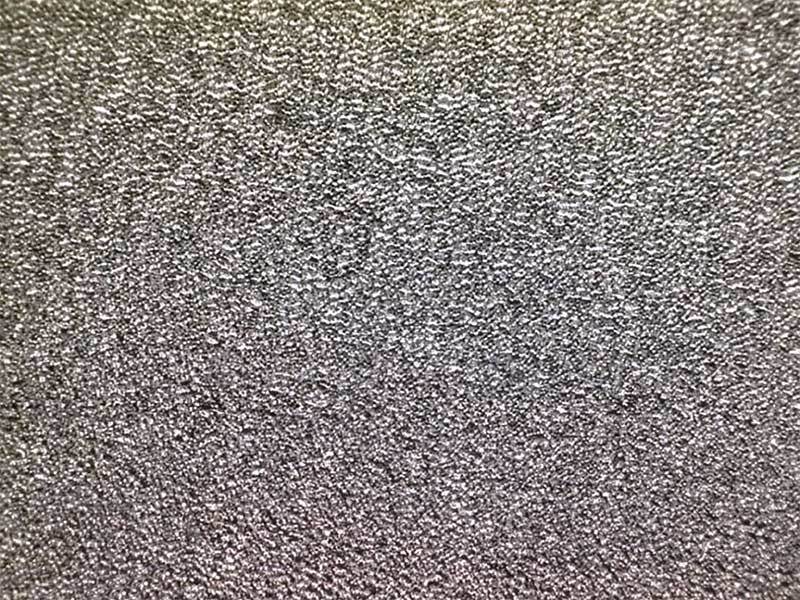

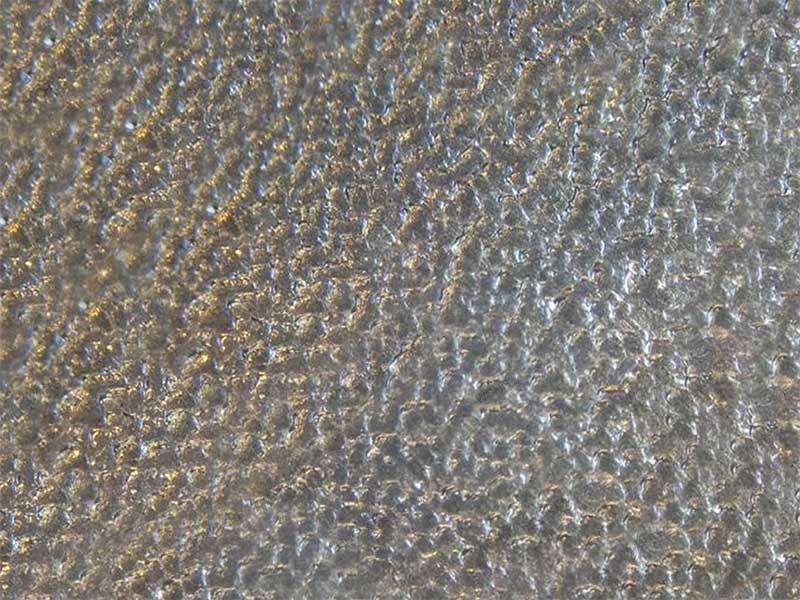

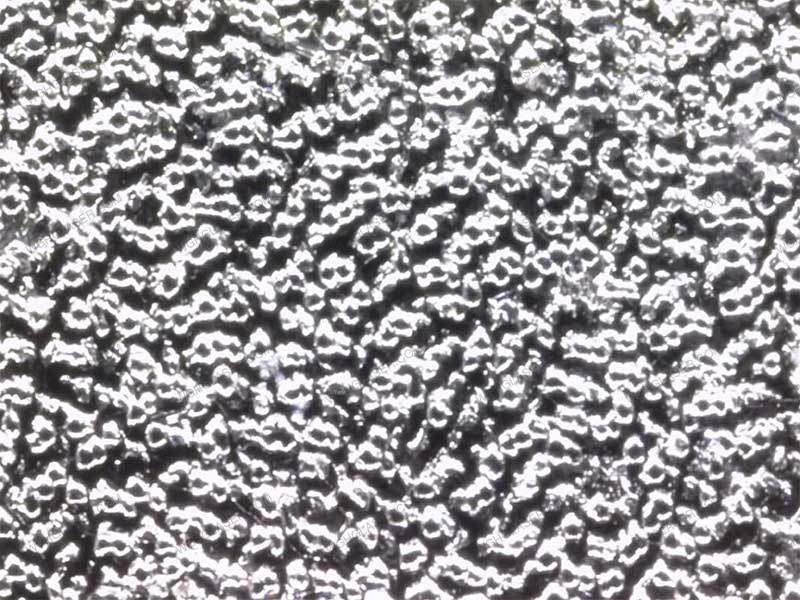

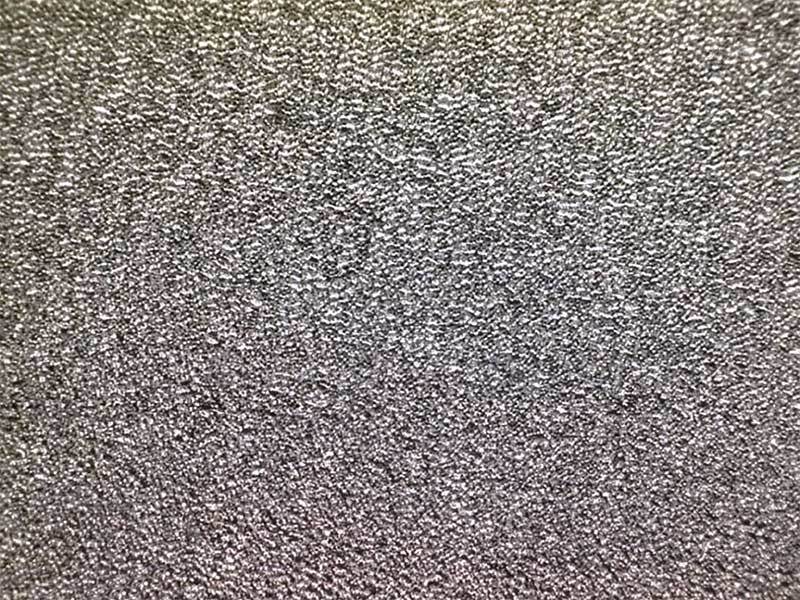

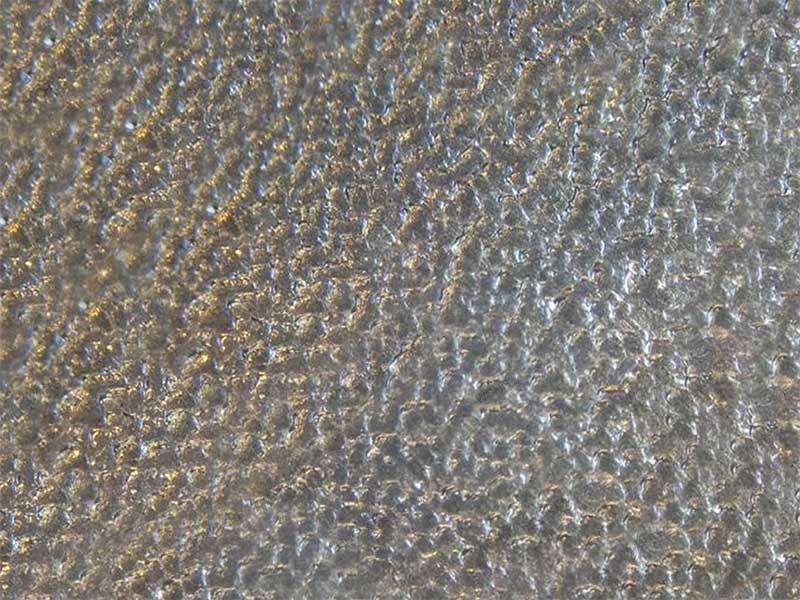

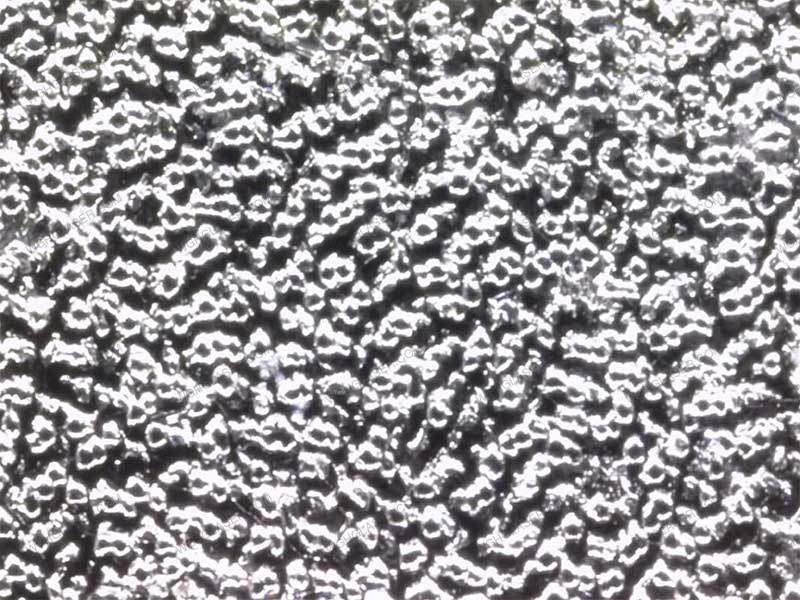

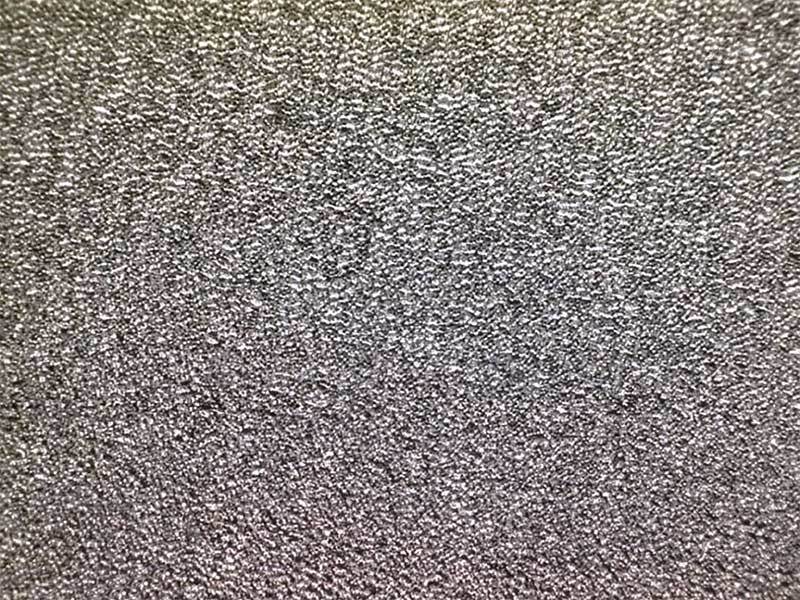

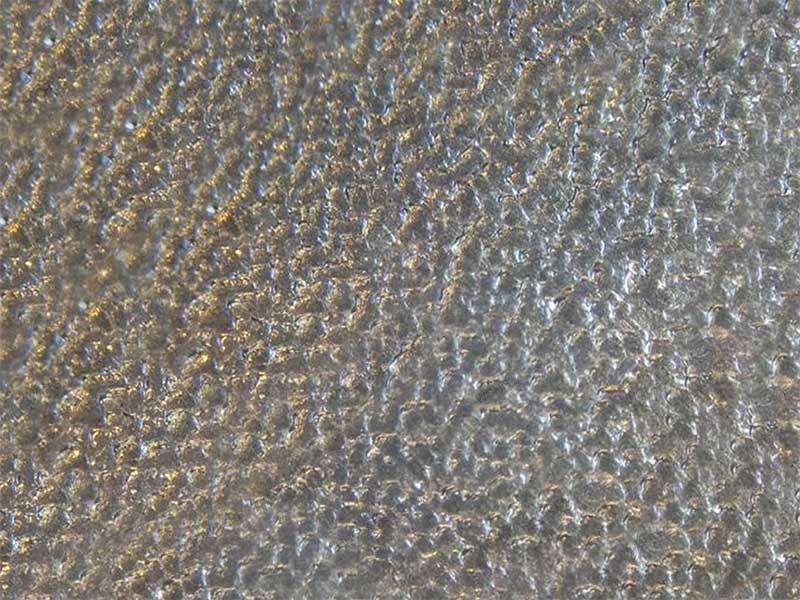

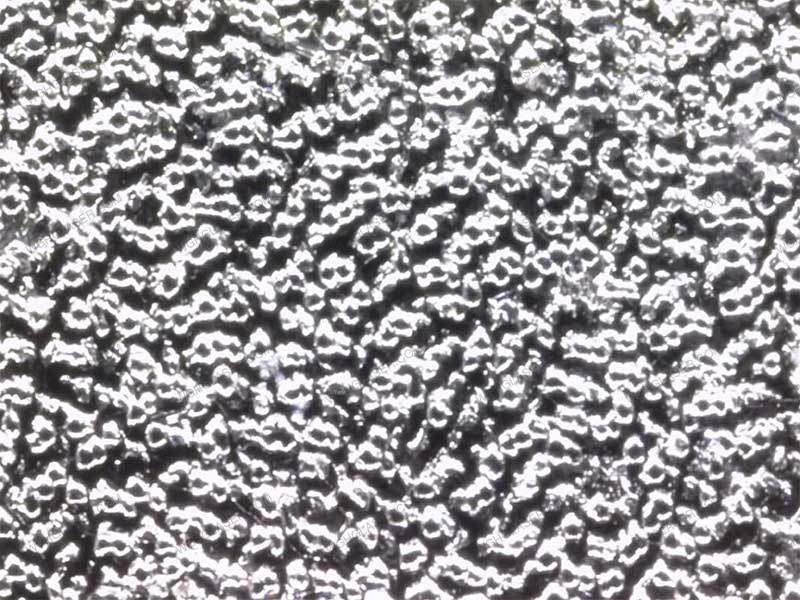

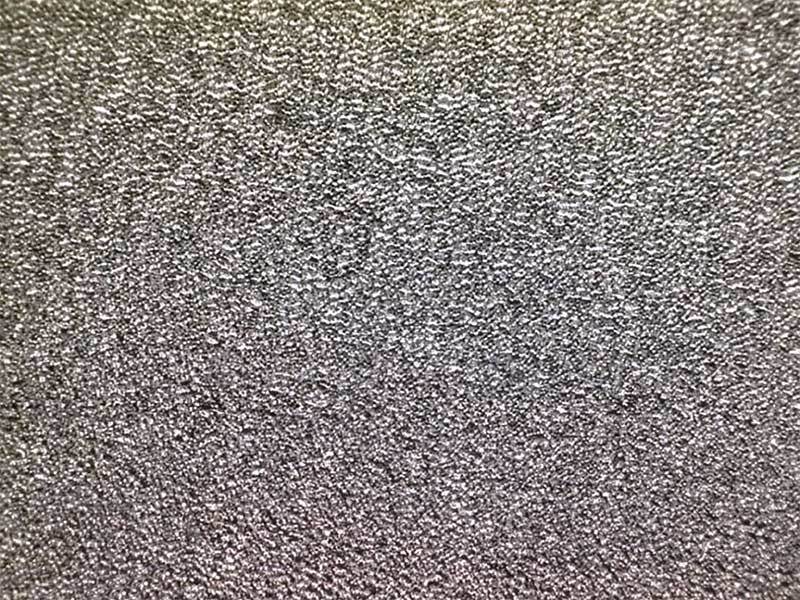

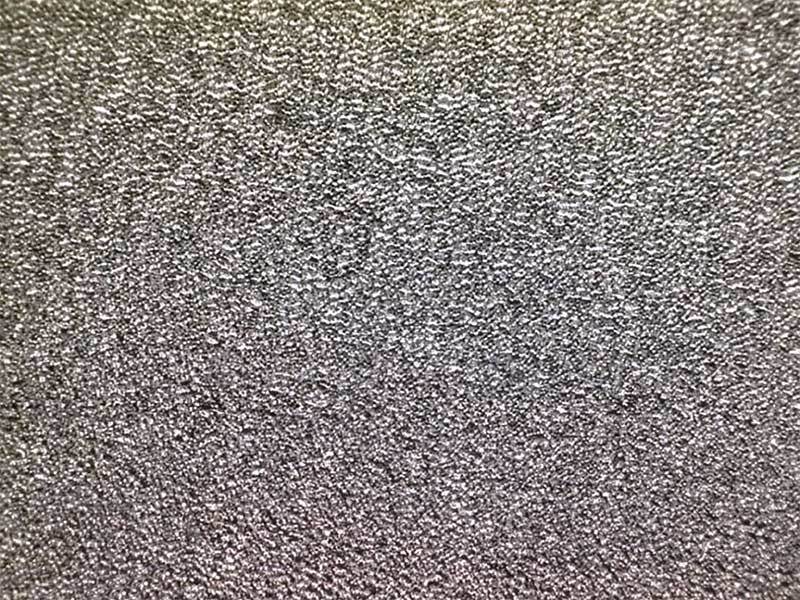

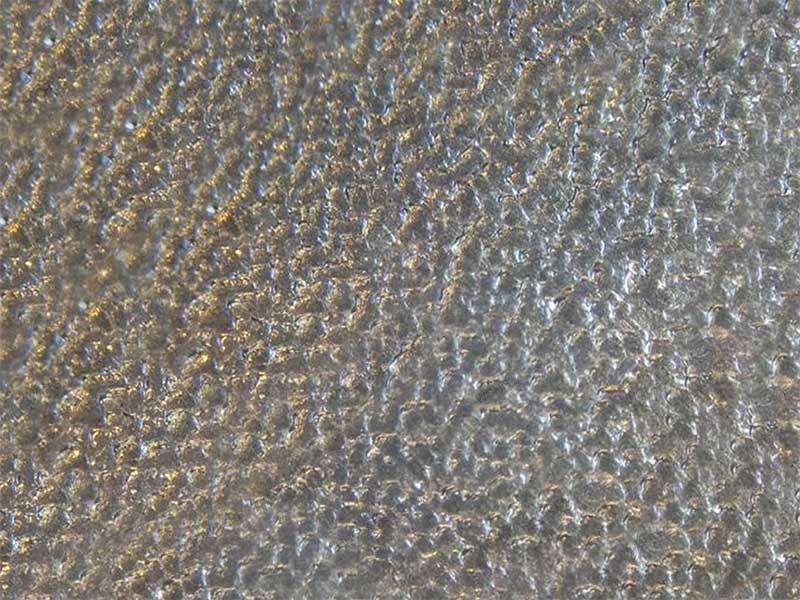

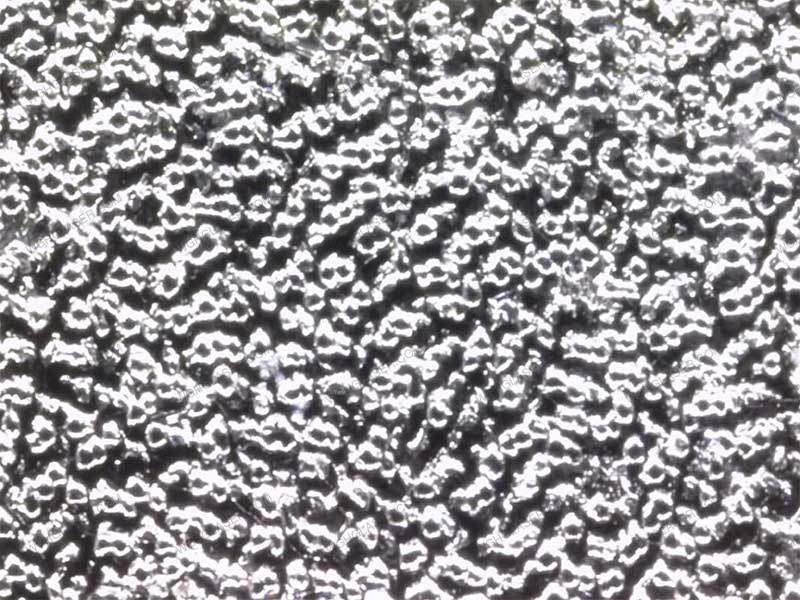

Sample Display

Laser Roughening

Laser Roughening

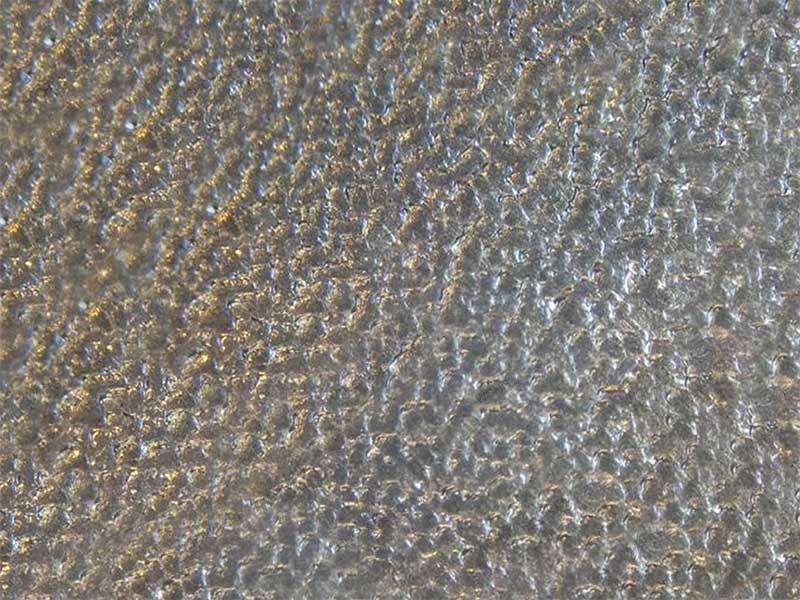

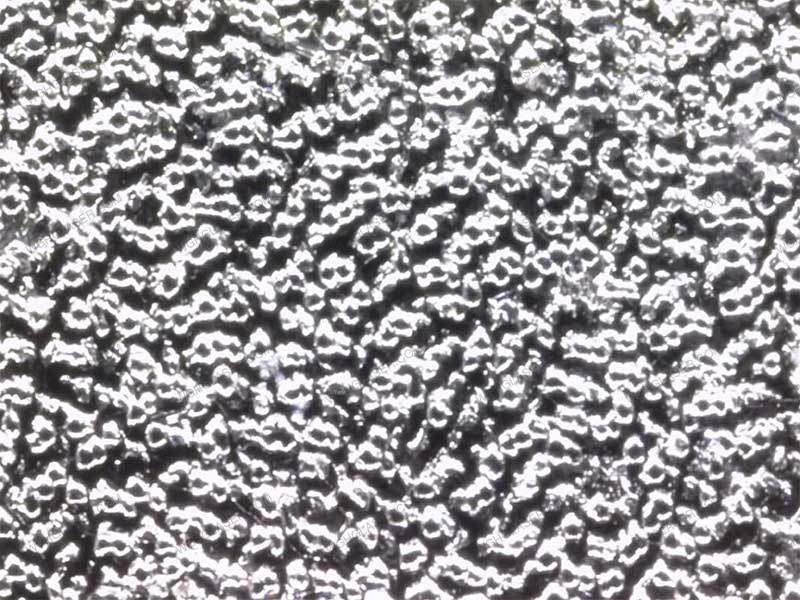

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

Application industry

The cold rolling texturing processing is meet the texturing requirements of various work rolls such as flattening mill, finishing mill, rolling mill, tandem mill and continuous rolling mill.

Categories

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JGK83 small roll laser texturing equipment

Product Description: The system consists of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering.

-

Application industry: steel, aluminum, titanium, non-ferrous metals and other industries

Applicable materials: titanium, aluminum, stainless steel, carbon steel, etc.

Laser Texturing Equipment of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering. The laser disordered texturing technology is independently developed and has a number of technical patents. At present, the system can realize single head and double head according to the number of lasers and texturing heads, and can be configured according to customer requirements.

Advantages Introduction:

higher control accuracy

The equipment is simple to operate

controllable morphology

low operating costs

Higher system integration,and more reliable stability.

Visual operation, easy to operate

Laser texturing processing has good uniformity, high repeatability and controllable morphology.

No pollution, low energy consumption, low noise, low operating costs.

Technical Parameters:

CNC System

Siemens CNC system 828D/840D (It can be customized).

Processing Roll Range

Diameter: Φ50mm~630mm

Roll total length: 0.5-6 meters

Roller Index after Texturing

Surface roughness Ra=0.5~15μm

Axial Linear Density

3~100 points/mm

Radial Line Density

disordered, frequency adjustable, up to 100KHz

Micro Pit Diameter

50~90μm

Micro Pit bulge Hardness

HV≥800

Micro Pit bulge Height

2~25μm

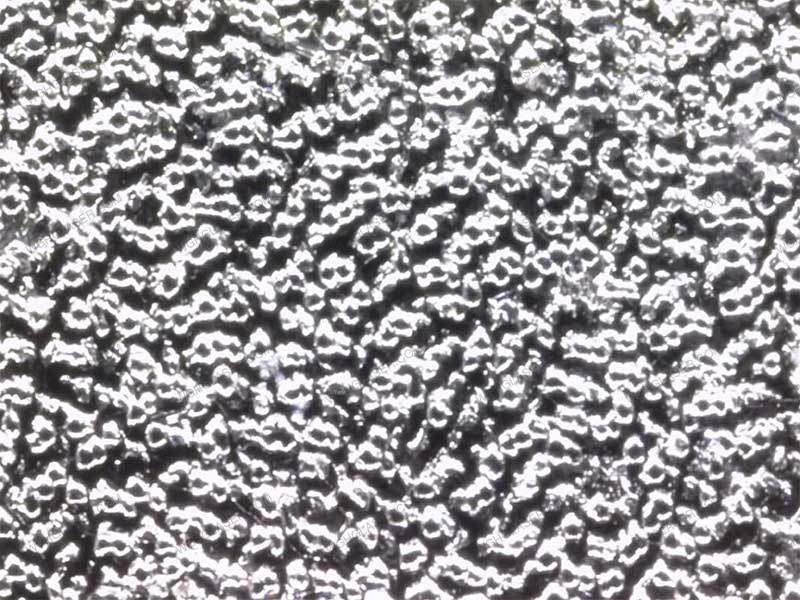

Sample Display

Laser Roughening

Laser Roughening

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

Application industry

The cold rolling texturing processing is meet the texturing requirements of various work rolls such as flattening mill, finishing mill, rolling mill, tandem mill and continuous rolling mill.

Categories

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

JGK83 small roll laser texturing equipment

Product Description: The system consists of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering.

-

Application industry: steel, aluminum, titanium, non-ferrous metals and other industries

Applicable materials: titanium, aluminum, stainless steel, carbon steel, etc.

Laser Texturing Equipment of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering. The laser disordered texturing technology is independently developed and has a number of technical patents. At present, the system can realize single head and double head according to the number of lasers and texturing heads, and can be configured according to customer requirements.

Advantages Introduction:

higher control accuracy

The equipment is simple to operate

controllable morphology

low operating costs

Higher system integration,and more reliable stability.

Visual operation, easy to operate

Laser texturing processing has good uniformity, high repeatability and controllable morphology.

No pollution, low energy consumption, low noise, low operating costs.

Technical Parameters:

CNC System

Siemens CNC system 828D/840D (It can be customized).

Processing Roll Range

Diameter: Φ50mm~630mm

Roll total length: 0.5-6 meters

Roller Index after Texturing

Surface roughness Ra=0.5~15μm

Axial Linear Density

3~100 points/mm

Radial Line Density

disordered, frequency adjustable, up to 100KHz

Micro Pit Diameter

50~90μm

Micro Pit bulge Hardness

HV≥800

Micro Pit bulge Height

2~25μm

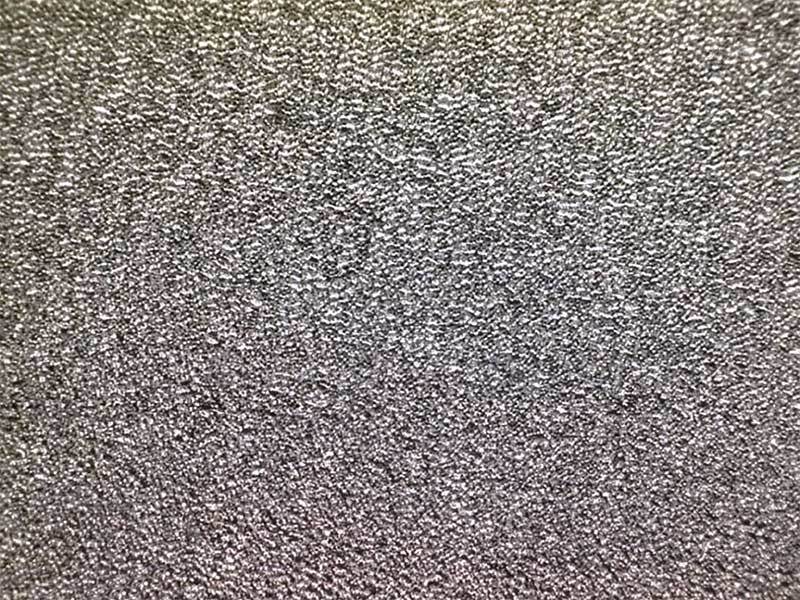

Sample Display

Laser Roughening

Laser Roughening

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

Application industry

The cold rolling texturing processing is meet the texturing requirements of various work rolls such as flattening mill, finishing mill, rolling mill, tandem mill and continuous rolling mill.

Categories

Laser Cleaning Equipment Series

JGK83 small roll laser texturing equipment

Product Description: The system consists of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering.

-

Application industry: steel, aluminum, titanium, non-ferrous metals and other industries

Applicable materials: titanium, aluminum, stainless steel, carbon steel, etc.

Laser Texturing Equipment of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering. The laser disordered texturing technology is independently developed and has a number of technical patents. At present, the system can realize single head and double head according to the number of lasers and texturing heads, and can be configured according to customer requirements.

Advantages Introduction:

higher control accuracy

The equipment is simple to operate

controllable morphology

low operating costs

Higher system integration,and more reliable stability.

Visual operation, easy to operate

Laser texturing processing has good uniformity, high repeatability and controllable morphology.

No pollution, low energy consumption, low noise, low operating costs.

Technical Parameters:

CNC System

Siemens CNC system 828D/840D (It can be customized).

Processing Roll Range

Diameter: Φ50mm~630mm

Roll total length: 0.5-6 meters

Roller Index after Texturing

Surface roughness Ra=0.5~15μm

Axial Linear Density

3~100 points/mm

Radial Line Density

disordered, frequency adjustable, up to 100KHz

Micro Pit Diameter

50~90μm

Micro Pit bulge Hardness

HV≥800

Micro Pit bulge Height

2~25μm

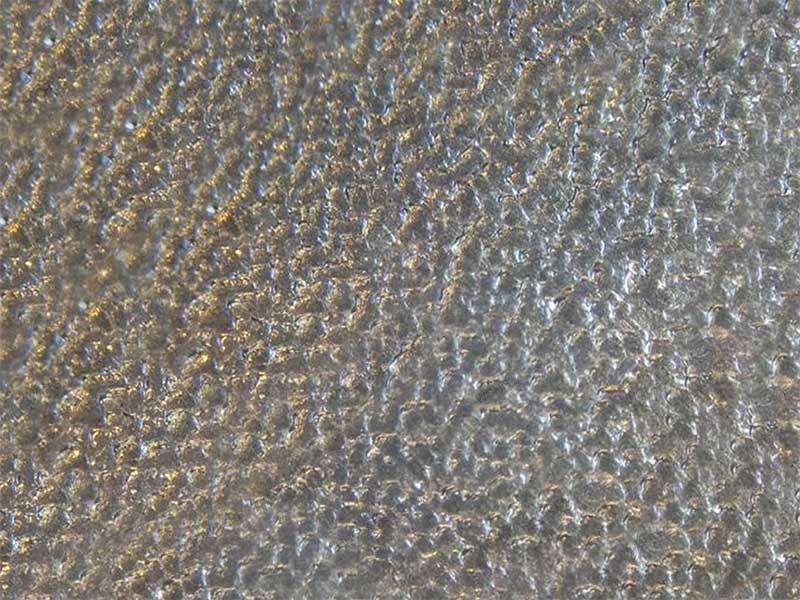

Sample Display

Laser Roughening

Laser Roughening

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

Application industry

The cold rolling texturing processing is meet the texturing requirements of various work rolls such as flattening mill, finishing mill, rolling mill, tandem mill and continuous rolling mill.

JGK83 small roll laser texturing equipment

Product Description: The system consists of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering.

-

Application industry: steel, aluminum, titanium, non-ferrous metals and other industries

Applicable materials: titanium, aluminum, stainless steel, carbon steel, etc.

Laser Texturing Equipment of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering. The laser disordered texturing technology is independently developed and has a number of technical patents. At present, the system can realize single head and double head according to the number of lasers and texturing heads, and can be configured according to customer requirements.

Advantages Introduction:

higher control accuracy

The equipment is simple to operate

controllable morphology

low operating costs

Higher system integration,and more reliable stability.

Visual operation, easy to operate

Laser texturing processing has good uniformity, high repeatability and controllable morphology.

No pollution, low energy consumption, low noise, low operating costs.

Technical Parameters:

CNC System

Siemens CNC system 828D/840D (It can be customized).

Processing Roll Range

Diameter: Φ50mm~630mm

Roll total length: 0.5-6 meters

Roller Index after Texturing

Surface roughness Ra=0.5~15μm

Axial Linear Density

3~100 points/mm

Radial Line Density

disordered, frequency adjustable, up to 100KHz

Micro Pit Diameter

50~90μm

Micro Pit bulge Hardness

HV≥800

Micro Pit bulge Height

2~25μm

Sample Display

Laser Roughening

Laser Roughening

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

Application industry

The cold rolling texturing processing is meet the texturing requirements of various work rolls such as flattening mill, finishing mill, rolling mill, tandem mill and continuous rolling mill.

JGK83 small roll laser texturing equipment

Product Description: The system consists of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering.

Application industry: steel, aluminum, titanium, non-ferrous metals and other industries

Applicable materials: titanium, aluminum, stainless steel, carbon steel, etc.

Laser Texturing Equipment of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering. The laser disordered texturing technology is independently developed and has a number of technical patents. At present, the system can realize single head and double head according to the number of lasers and texturing heads, and can be configured according to customer requirements.

Advantages Introduction:

Technical Parameters:

Sample Display

Application industry

The cold rolling texturing processing is meet the texturing requirements of various work rolls such as flattening mill, finishing mill, rolling mill, tandem mill and continuous rolling mill.

Applicable materials: titanium, aluminum, stainless steel, carbon steel, etc.

Laser Texturing Equipment of a fiber laser, a control system and a CNC roll machine. The laser disordered texturing processing can be realized, so that the surface of the roll is obtained with disordered surface, which satisfies various surface topography requirements. It can replace traditional blasting, EDM, and other laser ordering. The laser disordered texturing technology is independently developed and has a number of technical patents. At present, the system can realize single head and double head according to the number of lasers and texturing heads, and can be configured according to customer requirements.

Advantages Introduction:

| higher control accuracy | The equipment is simple to operate | controllable morphology | low operating costs |

| Higher system integration,and more reliable stability. | Visual operation, easy to operate | Laser texturing processing has good uniformity, high repeatability and controllable morphology. |

No pollution, low energy consumption, low noise, low operating costs. |

Technical Parameters:

| CNC System | Siemens CNC system 828D/840D (It can be customized). |

| Processing Roll Range | Diameter: Φ50mm~630mm Roll total length: 0.5-6 meters |

| Roller Index after Texturing | Surface roughness Ra=0.5~15μm |

| Axial Linear Density | 3~100 points/mm |

| Radial Line Density | disordered, frequency adjustable, up to 100KHz |

| Micro Pit Diameter | 50~90μm |

| Micro Pit bulge Hardness | HV≥800 |

| Micro Pit bulge Height | 2~25μm |

Sample Display

Laser Roughening

Laser Roughening

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

The surface of Laser Roughening Before and after comparison

Application industry

The cold rolling texturing processing is meet the texturing requirements of various work rolls such as flattening mill, finishing mill, rolling mill, tandem mill and continuous rolling mill.