Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

1600W High power Laser Cleaning Machine

Product Description: It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

-

Application industry: It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Applicable materials: steel, iron, aluminum, titanium and other metals, as well as ceramics.

It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

WISCO-HGlaser production line for hand-held laser cleaning, armored laser cleaning and laser cleaning can be customized according to the needs of different industries to meet the production needs.

Advantages Introduction:

Intelligent

High efficiency

High stability

No damage and pollution

Form product line operation, and the equipment can realize automatic operation and simple operation

Fast, clean and accurate cleaning to remove surface paint, coating and oxide layer

Life-time service and low operation cost

No damage to the base material, friendly to the environment and no secondary pollution

Technical Parameters

Parameters/ Power

50W

100W

200W

300W

500W

800 W

1000W

1200 W

1600 W

Fiber Length

3m

3m

3m

3/5/8m

10/15/20/50/100m

10m (Max 100m)

10/15/20/50/100m

10m (Max 100m)

Cleaning Scan Width

10-110mm(Adjustable)

10-160mm (Adjustable)

Input Power

Single-phase AC220V 50Hz

Three Phase n+E,400 volt AC(±10%)

Rust Removal Efficiency

1-3㎡/h

3-6㎡/h

5-10㎡/h

10-15㎡/h

15-20㎡/h

20-35㎡/h

35-45㎡/h

40-60㎡/h

60-90㎡/h

Degreasing Efficiency

2-6㎡/h

4-7㎡/h

6-12㎡/h

15-25㎡/h

18-28㎡/h

25-40㎡/h

40-60㎡/h

50-70㎡/h

70-100㎡/h

Remarks: Efficiency data is for reference only, the specific values are subject to actual conditions.

Sample Display

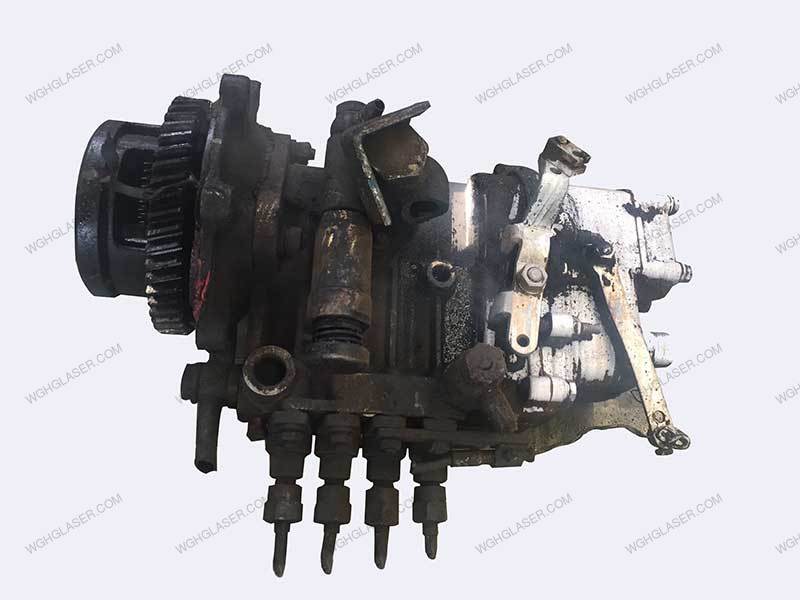

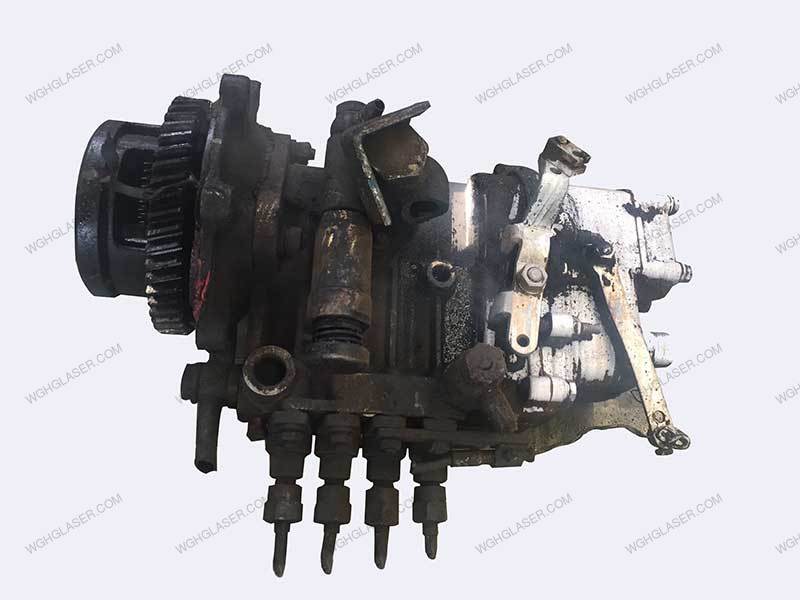

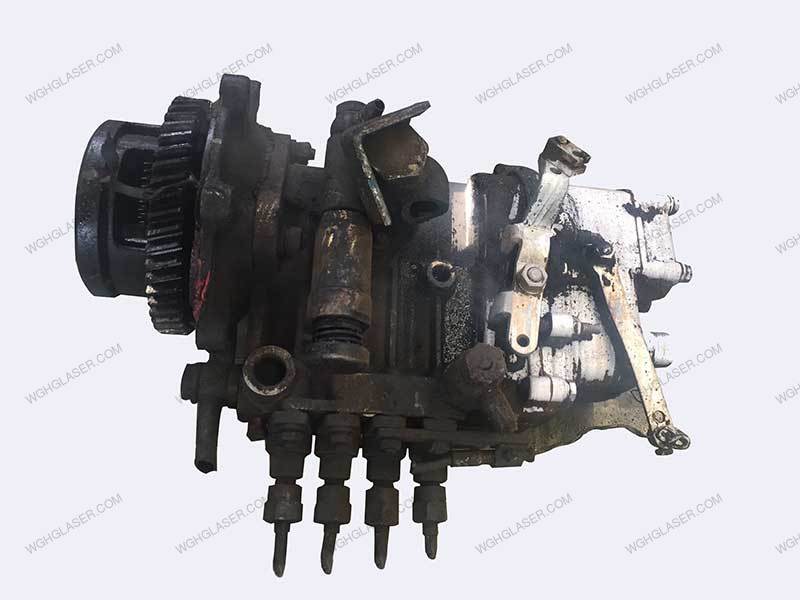

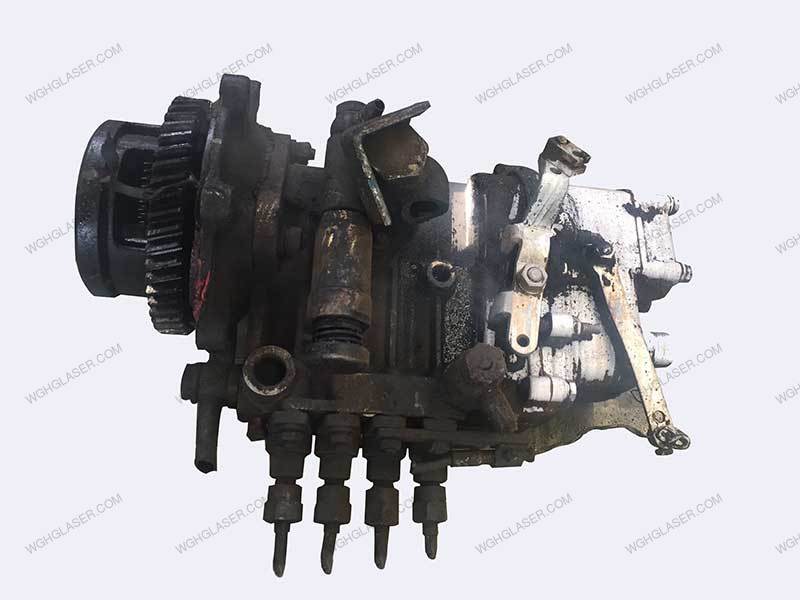

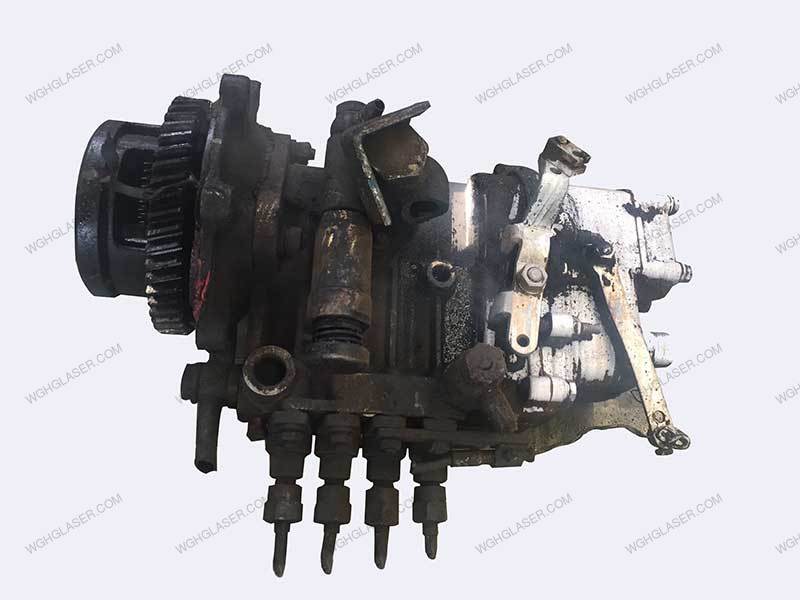

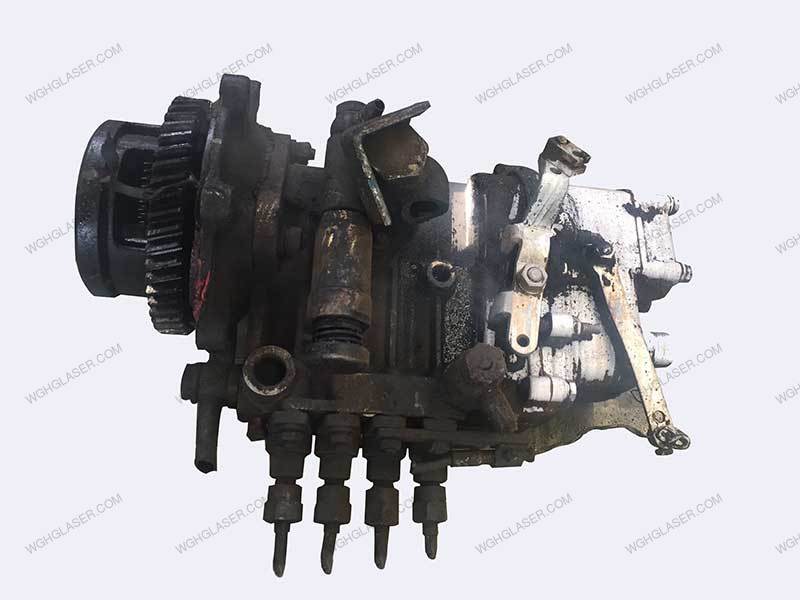

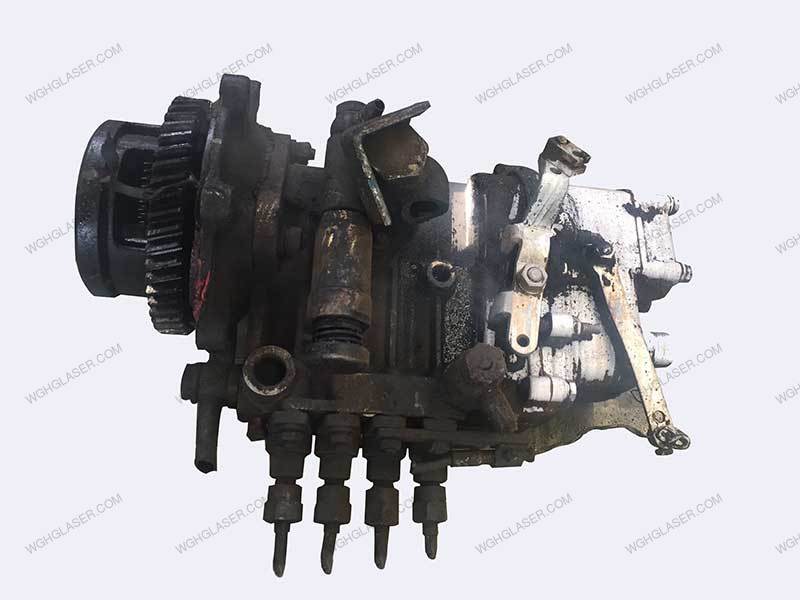

Laser derusting for engine

Laser derusting for train track

Laser cleaning for Car seat

Laser cleaning for car parts

Laser degreasing for Engine filter

Laser cleaning for Tanks chain

Laser oxide removal layer for Car parts

Laser oxide removal layer for track

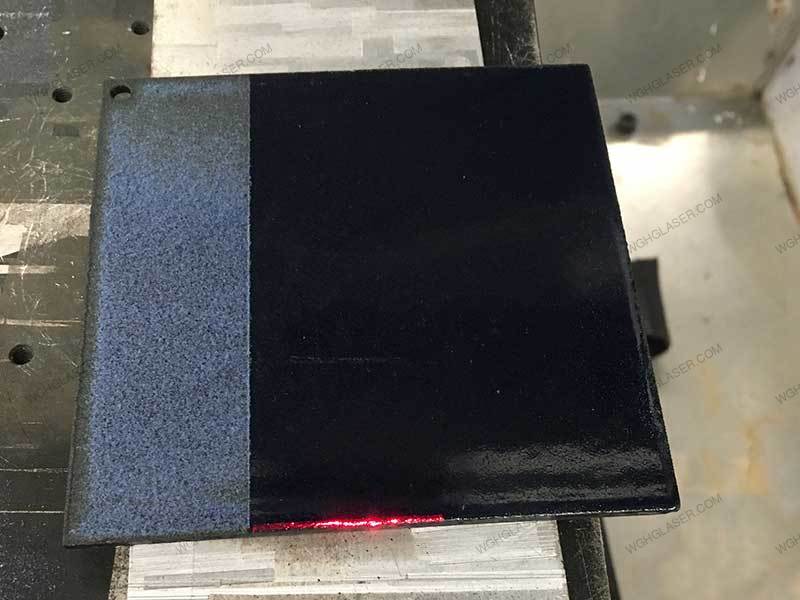

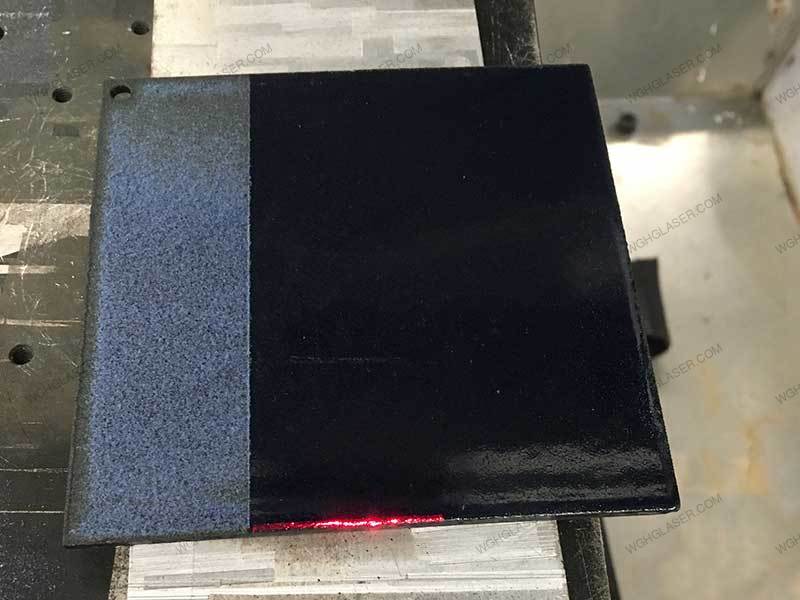

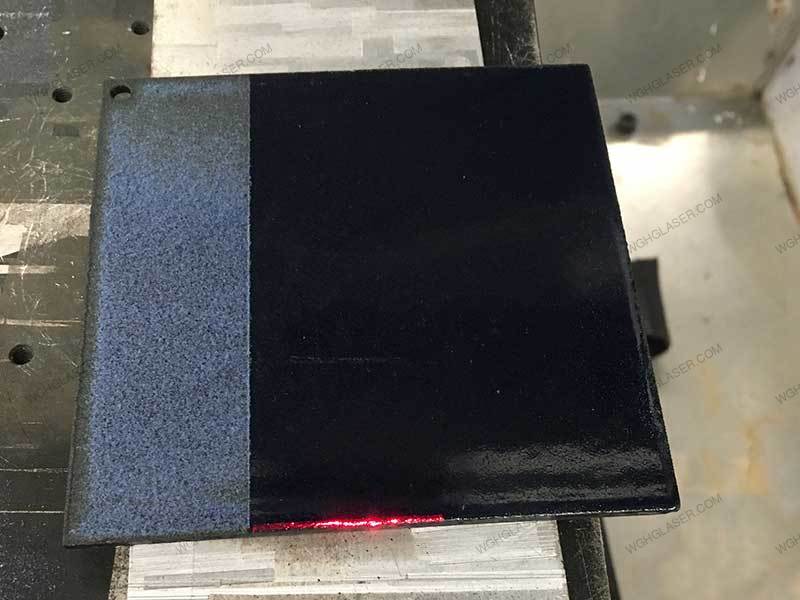

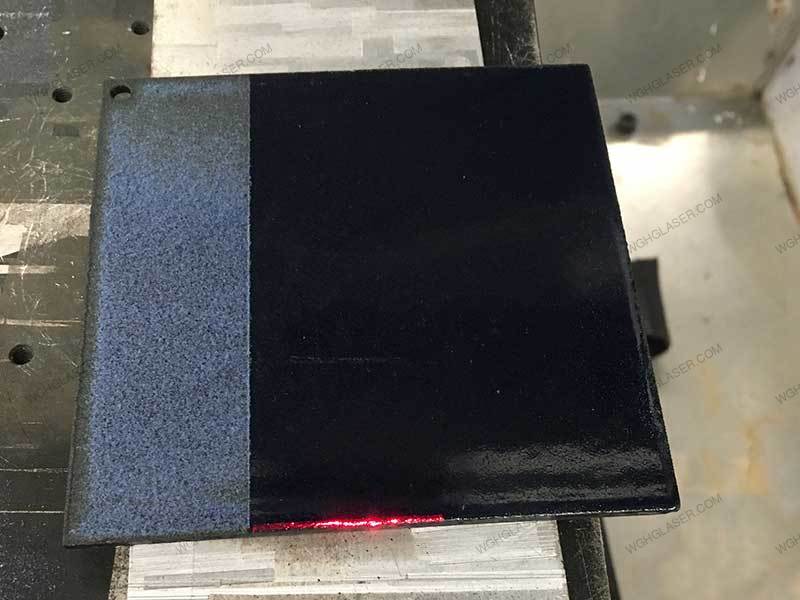

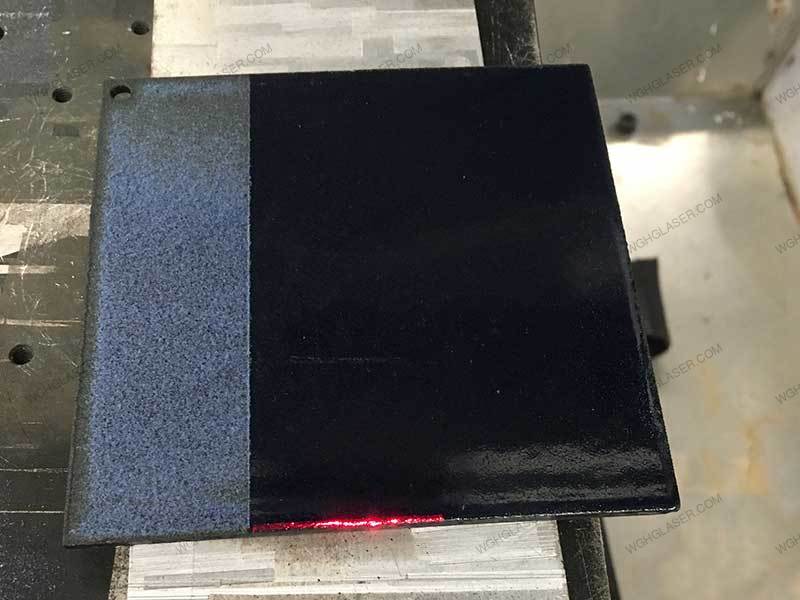

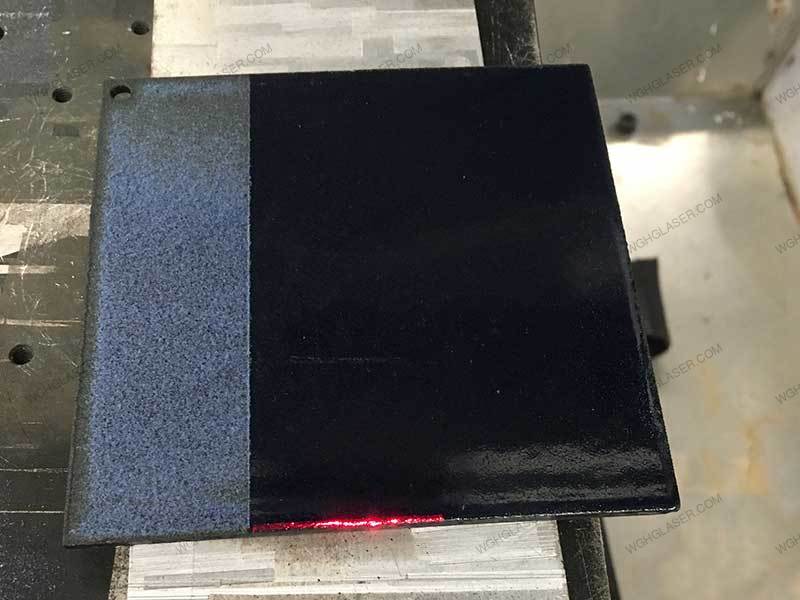

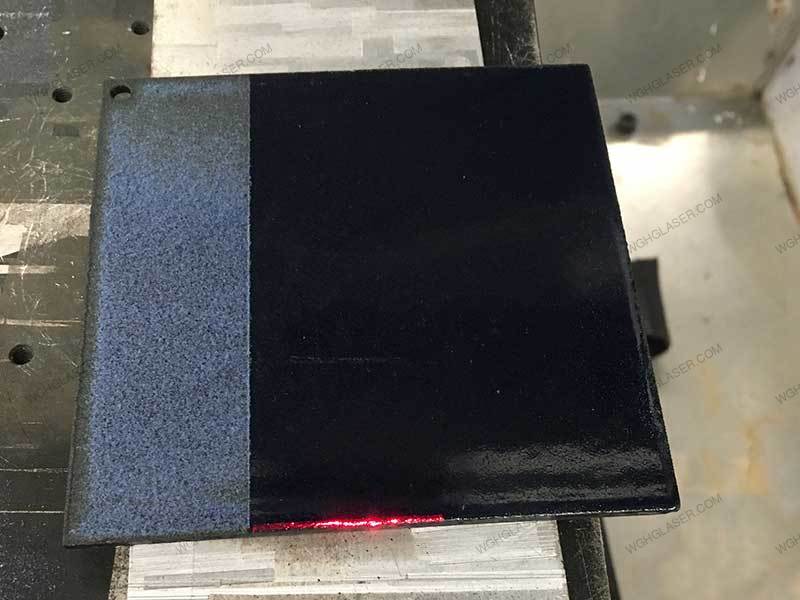

Laser removal of ceramics for Sheet metal

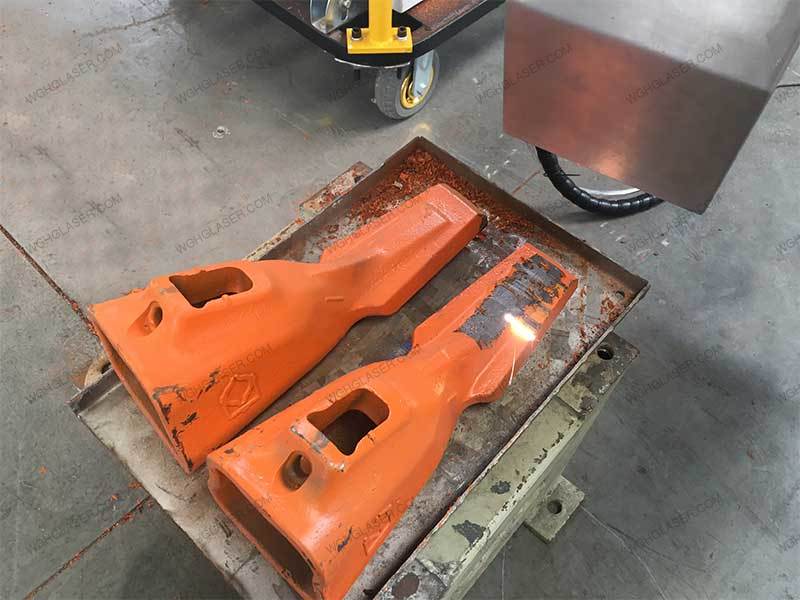

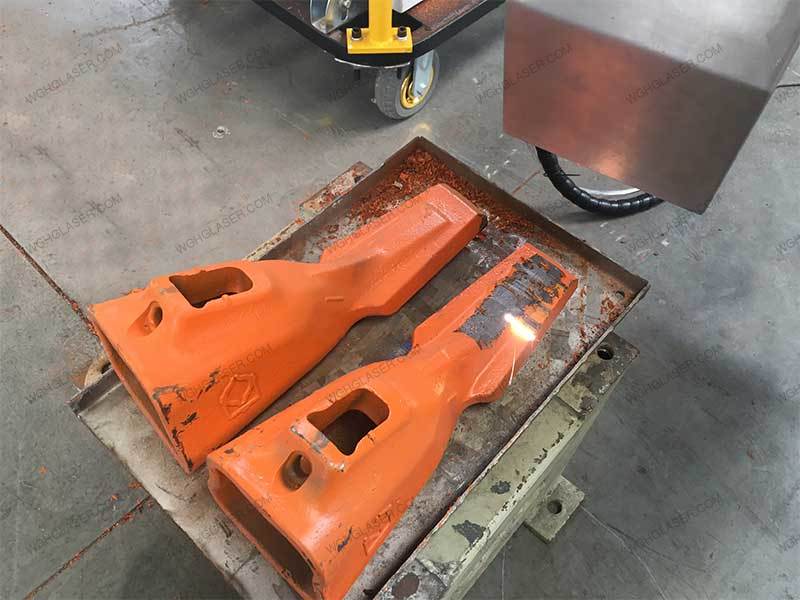

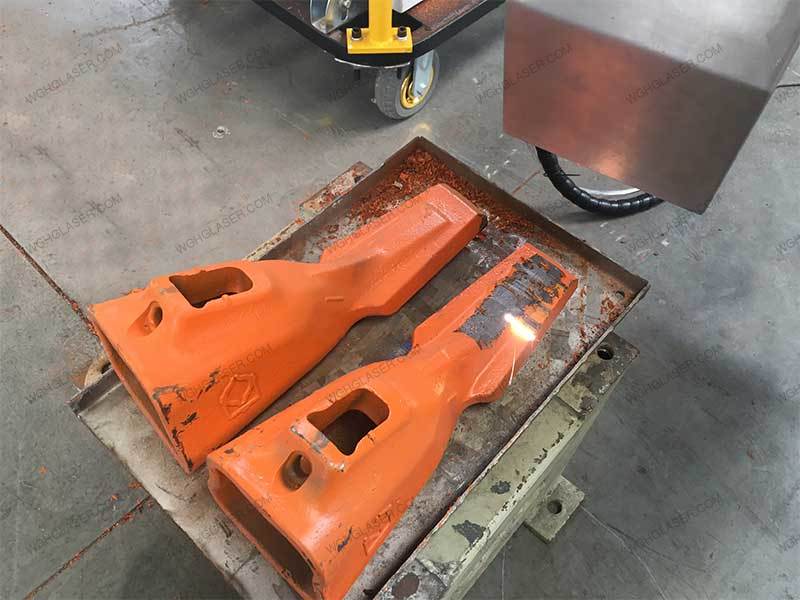

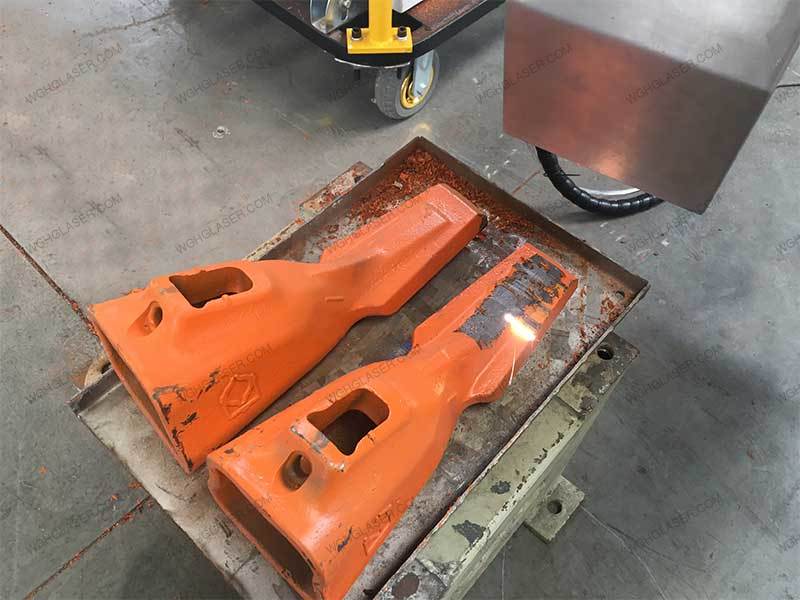

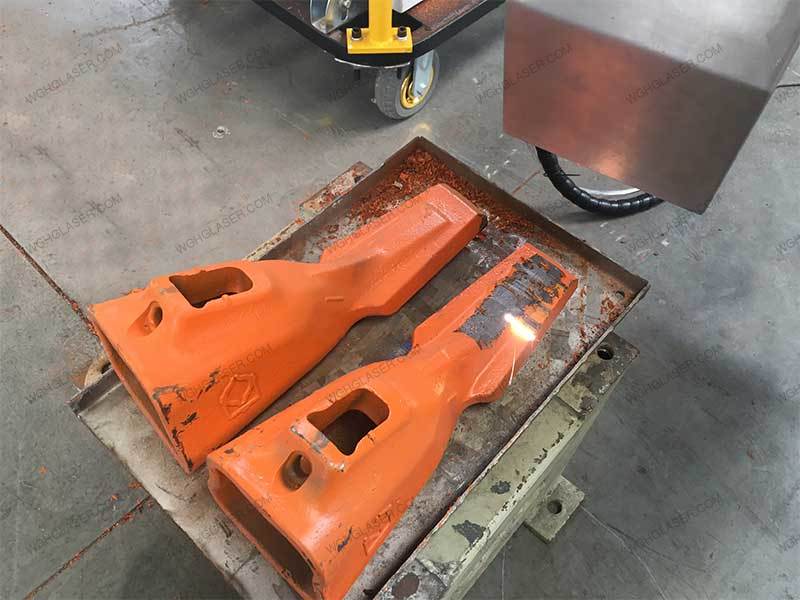

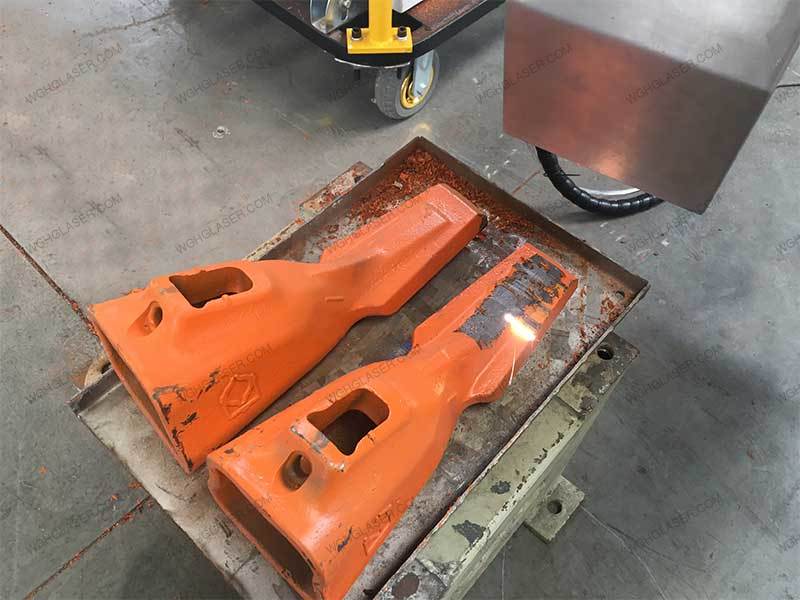

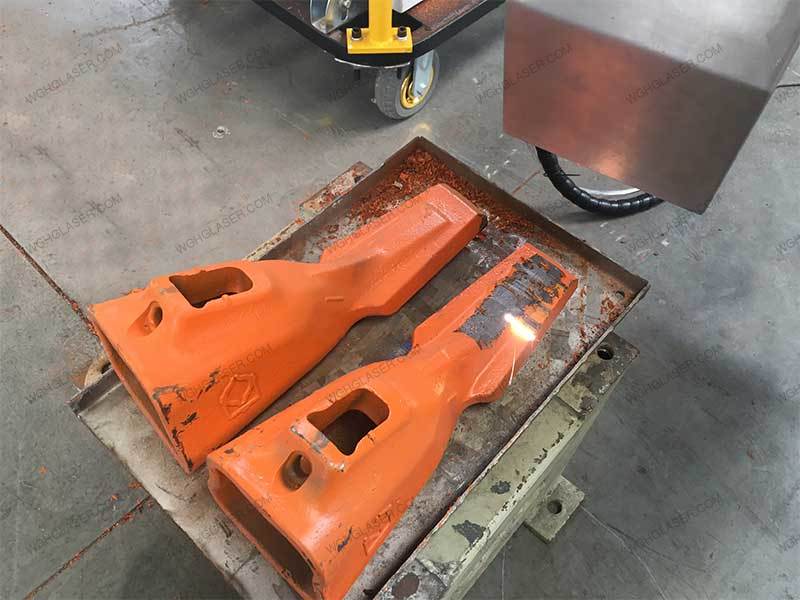

Laser paint removal for Cutter teeth

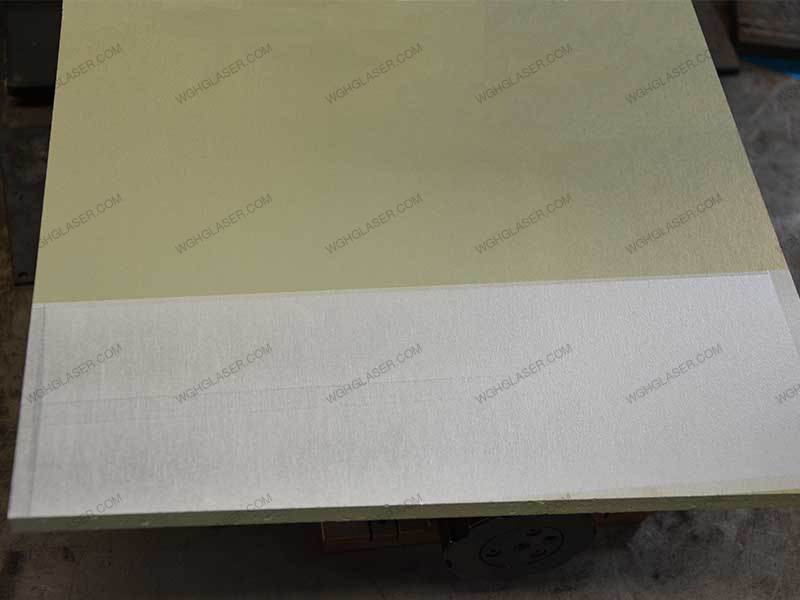

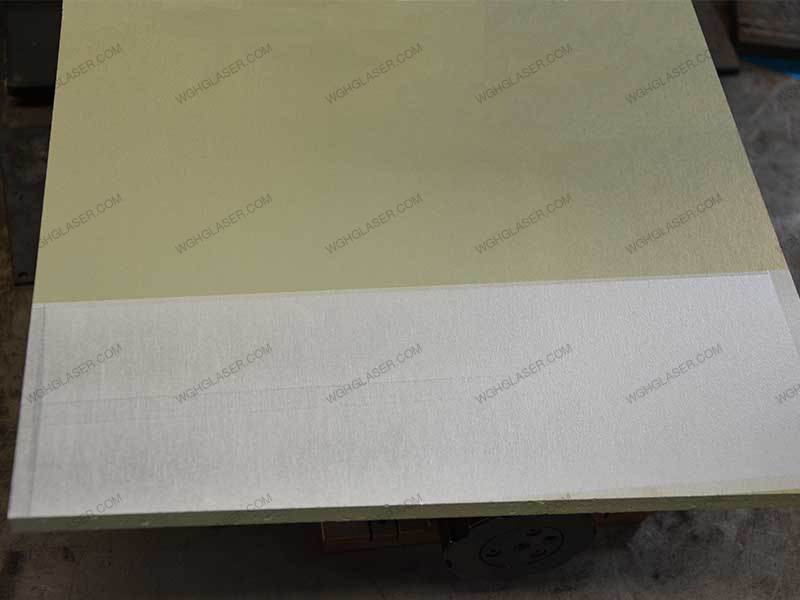

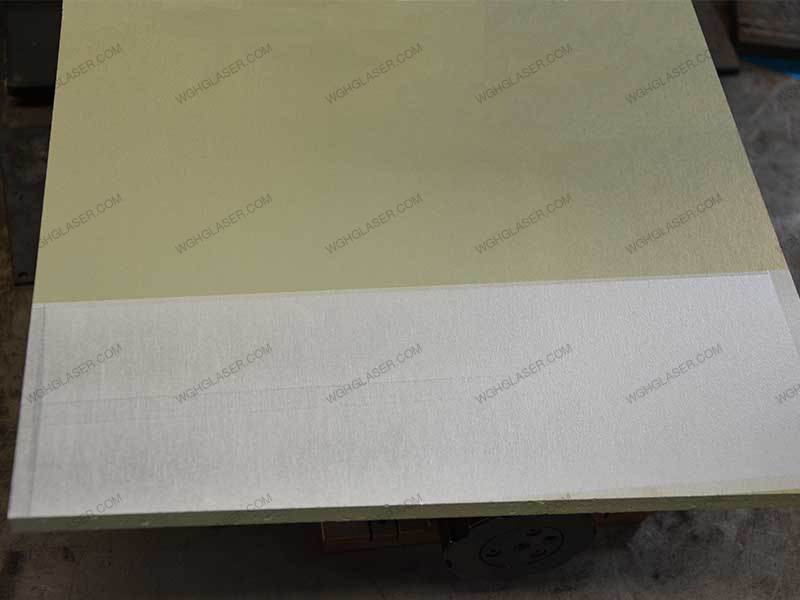

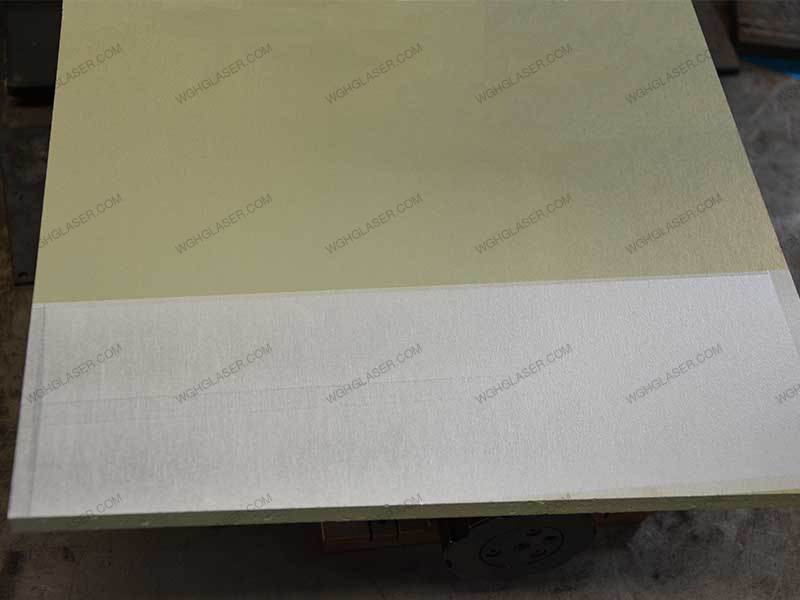

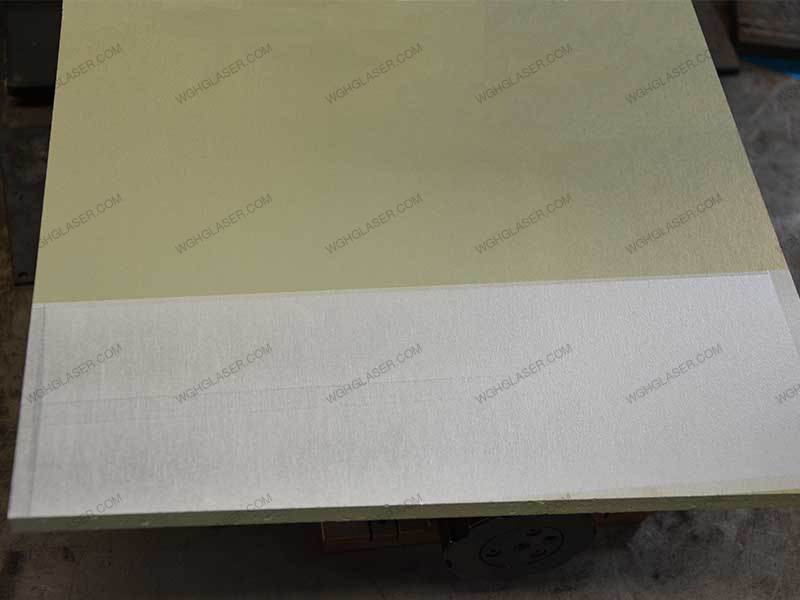

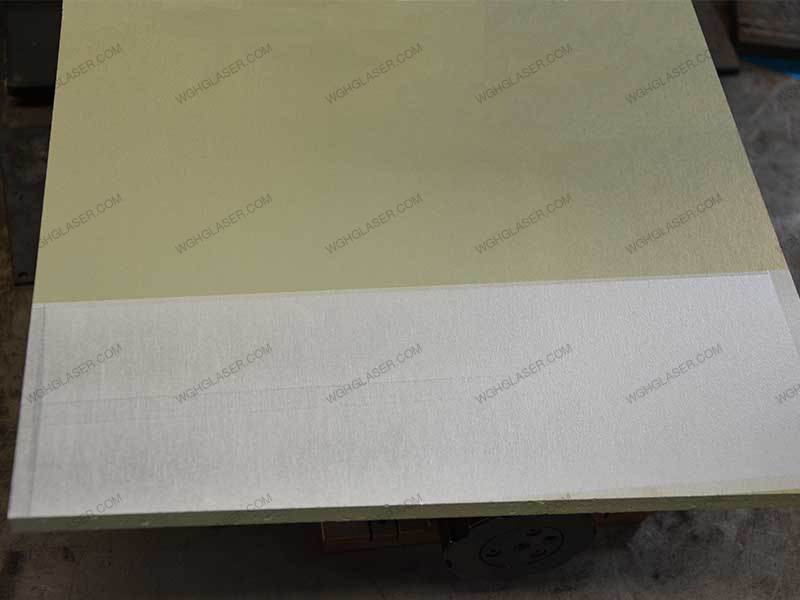

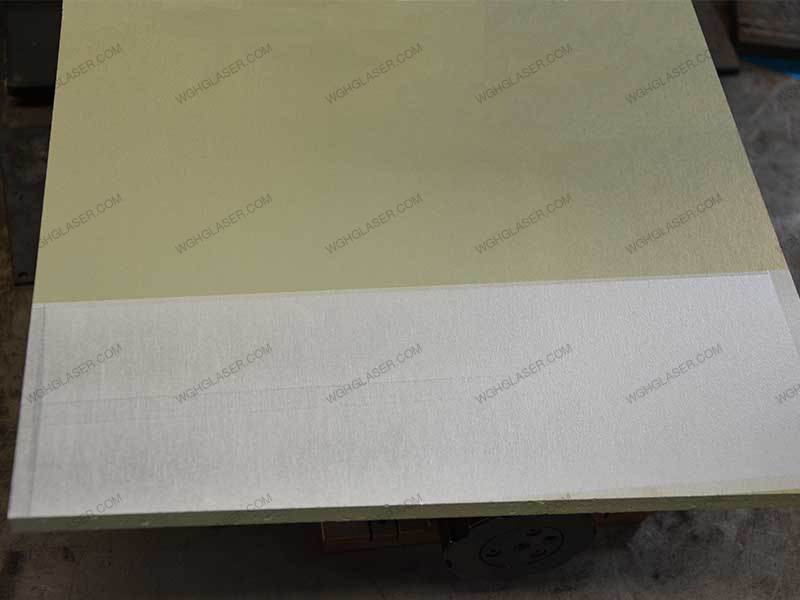

Laser paint removal for Aluminum plate

Laser glue removal for mold

Application industry

It is applied to surface laser degreasing, laser descaling, laser paint removal, laser zinc removal, laser film removal, laser de-coating and other laser cleaning processes. It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Categories

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

1600W High power Laser Cleaning Machine

Product Description: It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

-

Application industry: It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Applicable materials: steel, iron, aluminum, titanium and other metals, as well as ceramics.

It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

WISCO-HGlaser production line for hand-held laser cleaning, armored laser cleaning and laser cleaning can be customized according to the needs of different industries to meet the production needs.

Advantages Introduction:

Intelligent

High efficiency

High stability

No damage and pollution

Form product line operation, and the equipment can realize automatic operation and simple operation

Fast, clean and accurate cleaning to remove surface paint, coating and oxide layer

Life-time service and low operation cost

No damage to the base material, friendly to the environment and no secondary pollution

Technical Parameters

Parameters/ Power

50W

100W

200W

300W

500W

800 W

1000W

1200 W

1600 W

Fiber Length

3m

3m

3m

3/5/8m

10/15/20/50/100m

10m (Max 100m)

10/15/20/50/100m

10m (Max 100m)

Cleaning Scan Width

10-110mm(Adjustable)

10-160mm (Adjustable)

Input Power

Single-phase AC220V 50Hz

Three Phase n+E,400 volt AC(±10%)

Rust Removal Efficiency

1-3㎡/h

3-6㎡/h

5-10㎡/h

10-15㎡/h

15-20㎡/h

20-35㎡/h

35-45㎡/h

40-60㎡/h

60-90㎡/h

Degreasing Efficiency

2-6㎡/h

4-7㎡/h

6-12㎡/h

15-25㎡/h

18-28㎡/h

25-40㎡/h

40-60㎡/h

50-70㎡/h

70-100㎡/h

Remarks: Efficiency data is for reference only, the specific values are subject to actual conditions.

Sample Display

Laser derusting for engine

Laser derusting for train track

Laser cleaning for Car seat

Laser cleaning for car parts

Laser degreasing for Engine filter

Laser cleaning for Tanks chain

Laser oxide removal layer for Car parts

Laser oxide removal layer for track

Laser removal of ceramics for Sheet metal

Laser paint removal for Cutter teeth

Laser paint removal for Aluminum plate

Laser glue removal for mold

Application industry

It is applied to surface laser degreasing, laser descaling, laser paint removal, laser zinc removal, laser film removal, laser de-coating and other laser cleaning processes. It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Categories

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

1600W High power Laser Cleaning Machine

Product Description: It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

-

Application industry: It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Applicable materials: steel, iron, aluminum, titanium and other metals, as well as ceramics.

It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

WISCO-HGlaser production line for hand-held laser cleaning, armored laser cleaning and laser cleaning can be customized according to the needs of different industries to meet the production needs.

Advantages Introduction:

Intelligent

High efficiency

High stability

No damage and pollution

Form product line operation, and the equipment can realize automatic operation and simple operation

Fast, clean and accurate cleaning to remove surface paint, coating and oxide layer

Life-time service and low operation cost

No damage to the base material, friendly to the environment and no secondary pollution

Technical Parameters

Parameters/ Power

50W

100W

200W

300W

500W

800 W

1000W

1200 W

1600 W

Fiber Length

3m

3m

3m

3/5/8m

10/15/20/50/100m

10m (Max 100m)

10/15/20/50/100m

10m (Max 100m)

Cleaning Scan Width

10-110mm(Adjustable)

10-160mm (Adjustable)

Input Power

Single-phase AC220V 50Hz

Three Phase n+E,400 volt AC(±10%)

Rust Removal Efficiency

1-3㎡/h

3-6㎡/h

5-10㎡/h

10-15㎡/h

15-20㎡/h

20-35㎡/h

35-45㎡/h

40-60㎡/h

60-90㎡/h

Degreasing Efficiency

2-6㎡/h

4-7㎡/h

6-12㎡/h

15-25㎡/h

18-28㎡/h

25-40㎡/h

40-60㎡/h

50-70㎡/h

70-100㎡/h

Remarks: Efficiency data is for reference only, the specific values are subject to actual conditions.

Sample Display

Laser derusting for engine

Laser derusting for train track

Laser cleaning for Car seat

Laser cleaning for car parts

Laser degreasing for Engine filter

Laser cleaning for Tanks chain

Laser oxide removal layer for Car parts

Laser oxide removal layer for track

Laser removal of ceramics for Sheet metal

Laser paint removal for Cutter teeth

Laser paint removal for Aluminum plate

Laser glue removal for mold

Application industry

It is applied to surface laser degreasing, laser descaling, laser paint removal, laser zinc removal, laser film removal, laser de-coating and other laser cleaning processes. It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Categories

Laser Cleaning Equipment Series

1600W High power Laser Cleaning Machine

Product Description: It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

-

Application industry: It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Applicable materials: steel, iron, aluminum, titanium and other metals, as well as ceramics.

It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

WISCO-HGlaser production line for hand-held laser cleaning, armored laser cleaning and laser cleaning can be customized according to the needs of different industries to meet the production needs.

Advantages Introduction:

Intelligent

High efficiency

High stability

No damage and pollution

Form product line operation, and the equipment can realize automatic operation and simple operation

Fast, clean and accurate cleaning to remove surface paint, coating and oxide layer

Life-time service and low operation cost

No damage to the base material, friendly to the environment and no secondary pollution

Technical Parameters

Parameters/ Power

50W

100W

200W

300W

500W

800 W

1000W

1200 W

1600 W

Fiber Length

3m

3m

3m

3/5/8m

10/15/20/50/100m

10m (Max 100m)

10/15/20/50/100m

10m (Max 100m)

Cleaning Scan Width

10-110mm(Adjustable)

10-160mm (Adjustable)

Input Power

Single-phase AC220V 50Hz

Three Phase n+E,400 volt AC(±10%)

Rust Removal Efficiency

1-3㎡/h

3-6㎡/h

5-10㎡/h

10-15㎡/h

15-20㎡/h

20-35㎡/h

35-45㎡/h

40-60㎡/h

60-90㎡/h

Degreasing Efficiency

2-6㎡/h

4-7㎡/h

6-12㎡/h

15-25㎡/h

18-28㎡/h

25-40㎡/h

40-60㎡/h

50-70㎡/h

70-100㎡/h

Remarks: Efficiency data is for reference only, the specific values are subject to actual conditions.

Sample Display

Laser derusting for engine

Laser derusting for train track

Laser cleaning for Car seat

Laser cleaning for car parts

Laser degreasing for Engine filter

Laser cleaning for Tanks chain

Laser oxide removal layer for Car parts

Laser oxide removal layer for track

Laser removal of ceramics for Sheet metal

Laser paint removal for Cutter teeth

Laser paint removal for Aluminum plate

Laser glue removal for mold

Application industry

It is applied to surface laser degreasing, laser descaling, laser paint removal, laser zinc removal, laser film removal, laser de-coating and other laser cleaning processes. It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

1600W High power Laser Cleaning Machine

Product Description: It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

-

Application industry: It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Applicable materials: steel, iron, aluminum, titanium and other metals, as well as ceramics.

It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

WISCO-HGlaser production line for hand-held laser cleaning, armored laser cleaning and laser cleaning can be customized according to the needs of different industries to meet the production needs.

Advantages Introduction:

Intelligent

High efficiency

High stability

No damage and pollution

Form product line operation, and the equipment can realize automatic operation and simple operation

Fast, clean and accurate cleaning to remove surface paint, coating and oxide layer

Life-time service and low operation cost

No damage to the base material, friendly to the environment and no secondary pollution

Technical Parameters

Parameters/ Power

50W

100W

200W

300W

500W

800 W

1000W

1200 W

1600 W

Fiber Length

3m

3m

3m

3/5/8m

10/15/20/50/100m

10m (Max 100m)

10/15/20/50/100m

10m (Max 100m)

Cleaning Scan Width

10-110mm(Adjustable)

10-160mm (Adjustable)

Input Power

Single-phase AC220V 50Hz

Three Phase n+E,400 volt AC(±10%)

Rust Removal Efficiency

1-3㎡/h

3-6㎡/h

5-10㎡/h

10-15㎡/h

15-20㎡/h

20-35㎡/h

35-45㎡/h

40-60㎡/h

60-90㎡/h

Degreasing Efficiency

2-6㎡/h

4-7㎡/h

6-12㎡/h

15-25㎡/h

18-28㎡/h

25-40㎡/h

40-60㎡/h

50-70㎡/h

70-100㎡/h

Remarks: Efficiency data is for reference only, the specific values are subject to actual conditions.

Sample Display

Laser derusting for engine

Laser derusting for train track

Laser cleaning for Car seat

Laser cleaning for car parts

Laser degreasing for Engine filter

Laser cleaning for Tanks chain

Laser oxide removal layer for Car parts

Laser oxide removal layer for track

Laser removal of ceramics for Sheet metal

Laser paint removal for Cutter teeth

Laser paint removal for Aluminum plate

Laser glue removal for mold

Application industry

It is applied to surface laser degreasing, laser descaling, laser paint removal, laser zinc removal, laser film removal, laser de-coating and other laser cleaning processes. It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

1600W High power Laser Cleaning Machine

Product Description: It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

Application industry: It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Applicable materials: steel, iron, aluminum, titanium and other metals, as well as ceramics.

It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

WISCO-HGlaser production line for hand-held laser cleaning, armored laser cleaning and laser cleaning can be customized according to the needs of different industries to meet the production needs.

Advantages Introduction:

Technical Parameters

Remarks: Efficiency data is for reference only, the specific values are subject to actual conditions.

Sample Display

Application industry

It is applied to surface laser degreasing, laser descaling, laser paint removal, laser zinc removal, laser film removal, laser de-coating and other laser cleaning processes. It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.

Applicable materials: steel, iron, aluminum, titanium and other metals, as well as ceramics.

It is composed of laser, industrial robot, laser optical system and control system. It is suitable for high-volume production or large-area production environment. It provides 50-1600W (customizable) laser cleaning machine to meet surface laser degreasing and laser rust removal, laser paint removal, laser zinc removal, laser film removal, and coating removal, etc. cleaning processes.

WISCO-HGlaser production line for hand-held laser cleaning, armored laser cleaning and laser cleaning can be customized according to the needs of different industries to meet the production needs.

Advantages Introduction:

| Intelligent | High efficiency | High stability | No damage and pollution |

| Form product line operation, and the equipment can realize automatic operation and simple operation | Fast, clean and accurate cleaning to remove surface paint, coating and oxide layer | Life-time service and low operation cost | No damage to the base material, friendly to the environment and no secondary pollution |

Technical Parameters

| Parameters/ Power | 50W | 100W | 200W | 300W | 500W | 800 W | 1000W | 1200 W | 1600 W |

| Fiber Length | 3m | 3m | 3m | 3/5/8m | 10/15/20/50/100m | 10m (Max 100m) | 10/15/20/50/100m | 10m (Max 100m) | |

| Cleaning Scan Width | 10-110mm(Adjustable) | 10-160mm (Adjustable) | |||||||

| Input Power | Single-phase AC220V 50Hz | Three Phase n+E,400 volt AC(±10%) | |||||||

| Rust Removal Efficiency | 1-3㎡/h | 3-6㎡/h | 5-10㎡/h | 10-15㎡/h | 15-20㎡/h | 20-35㎡/h | 35-45㎡/h | 40-60㎡/h | 60-90㎡/h |

| Degreasing Efficiency | 2-6㎡/h | 4-7㎡/h | 6-12㎡/h | 15-25㎡/h | 18-28㎡/h | 25-40㎡/h | 40-60㎡/h | 50-70㎡/h | 70-100㎡/h |

Remarks: Efficiency data is for reference only, the specific values are subject to actual conditions.

Sample Display

Laser derusting for engine

Laser derusting for train track

Laser cleaning for Car seat

Laser cleaning for car parts

Laser degreasing for Engine filter

Laser cleaning for Tanks chain

Laser oxide removal layer for Car parts

Laser oxide removal layer for track

Laser removal of ceramics for Sheet metal

Laser paint removal for Cutter teeth

Laser paint removal for Aluminum plate

Laser glue removal for mold

Application industry

It is applied to surface laser degreasing, laser descaling, laser paint removal, laser zinc removal, laser film removal, laser de-coating and other laser cleaning processes. It is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military and other fields.