The application advantage of laser cladding in shaft repair

With the mechanical more continuous and more automation the production efficiency has been damanderd higher As a part of machinery used in industrial production, shaft is easy to cause shaft wear due to long-term over-negative operation, poor lubrication, impurities, external impact and other factors, thus affecting production. Choosing a quick and effective repair method to solve problems and reduce maintenance costs can effectively improve enterprise efficiency and ensure the maximum benefit of the enterprise.

Traditional solutions such as repair welding or surfacing machining, welding, etc., Can not fundamentally solve the problem, and dangerous, such as high temperature deformation, cracks, coating fall off; At the same time these traditional methods can not improvement to the equipment management.

Traditional solutions such as repair welding or surfacing machining, welding, etc., Can not fundamentally solve the problem, and dangerous, such as high temperature deformation, cracks, coating fall off; At the same time these traditional methods can not improvement to the equipment management.

Laser cladding repair technology , the use of high energy laser as a heat source, metal alloy materials (powder, paste, filiform, etc.) as a welding material, synchronized alloy material with laser rapid melting molten pool formation, ACTS on the metal surface and rapid solidification of dense, uniform and controllable metallurgical bonding layer thickness,surface repair for provides a good way.

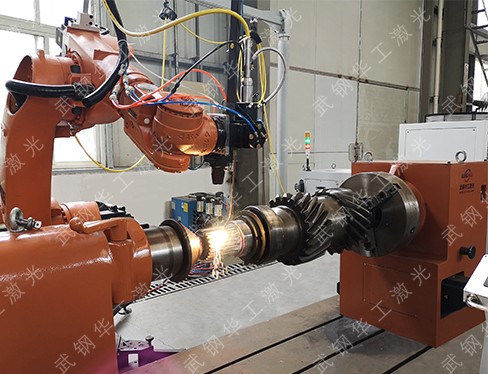

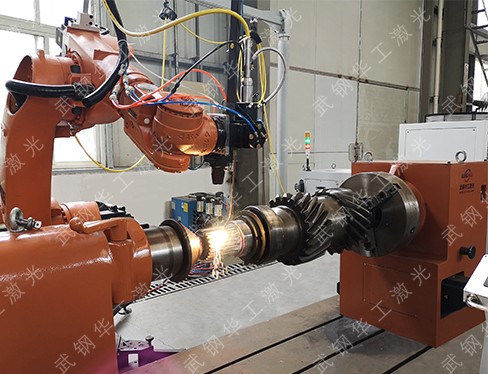

shaft high speed laser cladding

The advantages of laser cladding in shaft repair as follows:

1) To optimize the surface of the shaft, the laser cladding can form an alloy coating with completely different components and properties that is mutually fused with the matrix on the shaft surface. Because the substrate melting layer is very thin, it has little influence on the composition of the cladding layer. We can prepare the surface coating with heat resistance, corrosion resistance, abrasion resistance, oxidation resistance, fatigue resistance or optical, electrical and magnetic properties according to the specific requirements, thus effectively improving the performance of the shaft surface.

2) metallurgical bonding strength is high, the laser cladding process, cladding material to join by melt completely, make it become the theme of the alloy cladding layer, and matrix alloy also have a thin layer of melt, and theme alloy form metallurgical combination, not easy to fall off, has solved the traditional electroplating, spray, etc in the process of cold working problem of poor bonding strength of coating and the magnesium substrate.

3) Low deformation of heat input, rapid heating and rapid cooling of laser cladding have little impact on the substrate, and the dilution rate is ≤5-8%, thus solving a series of technical problems such as thermal deformation and thermal fatigue damage that are inevitable in traditional welding and tiG welding thermal processing.

Laser repair shaft item application case

Gear shaft laser repair

Laser repair of gear shaft tooth surface

Laser repair of motor electric wheel

Oil stem laser repair for shaft base

Laser repair can not only repair the worn shaft, but also cladding the wear resistant layer on the new shaft surface, so as to effectively improve the wear resistance and corrosion resistance of the shaft and increase its service life.

Laser cladding technology can be used not only on the rotary body, but also on the plane and complex surface. Therefore, it is also widely used in the repair and remanufacturing of mill marks, hydraulic supports, blades, scraper grooves, hydraulic cylinders, gears, die casting molds and so on.

Quality creates brand, professional achieves high quality! WG-HG Laser have a professional team, rich experience, warm service and good prestige. Whether you need laser cladding equipment or laser cladding processing business, HG-HG laser share total win.PLS contact us for more detailed information.

Laser cladding repair technology , the use of high energy laser as a heat source, metal alloy materials (powder, paste, filiform, etc.) as a welding material, synchronized alloy material with laser rapid melting molten pool formation, ACTS on the metal surface and rapid solidification of dense, uniform and controllable metallurgical bonding layer thickness,surface repair for provides a good way.

shaft high speed laser cladding

The advantages of laser cladding in shaft repair as follows:

1) To optimize the surface of the shaft, the laser cladding can form an alloy coating with completely different components and properties that is mutually fused with the matrix on the shaft surface. Because the substrate melting layer is very thin, it has little influence on the composition of the cladding layer. We can prepare the surface coating with heat resistance, corrosion resistance, abrasion resistance, oxidation resistance, fatigue resistance or optical, electrical and magnetic properties according to the specific requirements, thus effectively improving the performance of the shaft surface.

2) metallurgical bonding strength is high, the laser cladding process, cladding material to join by melt completely, make it become the theme of the alloy cladding layer, and matrix alloy also have a thin layer of melt, and theme alloy form metallurgical combination, not easy to fall off, has solved the traditional electroplating, spray, etc in the process of cold working problem of poor bonding strength of coating and the magnesium substrate.

3) Low deformation of heat input, rapid heating and rapid cooling of laser cladding have little impact on the substrate, and the dilution rate is ≤5-8%, thus solving a series of technical problems such as thermal deformation and thermal fatigue damage that are inevitable in traditional welding and tiG welding thermal processing.

Laser repair shaft item application case

Gear shaft laser repair

Laser repair of gear shaft tooth surface

Laser repair of motor electric wheel

Oil stem laser repair for shaft base

Laser repair can not only repair the worn shaft, but also cladding the wear resistant layer on the new shaft surface, so as to effectively improve the wear resistance and corrosion resistance of the shaft and increase its service life.

Laser cladding technology can be used not only on the rotary body, but also on the plane and complex surface. Therefore, it is also widely used in the repair and remanufacturing of mill marks, hydraulic supports, blades, scraper grooves, hydraulic cylinders, gears, die casting molds and so on.

Quality creates brand, professional achieves high quality! WG-HG Laser have a professional team, rich experience, warm service and good prestige. Whether you need laser cladding equipment or laser cladding processing business, HG-HG laser share total win.PLS contact us for more detailed information.