laser surface treatment technology in mechanical gear

The main applications of laser surface treatment technology in mechanical gears include laser surface quenching and laser cladding repair.

I. Laser surface quenching

Gears are widely used in all walks of life. Due to the working characteristics of the gear, the central part of the gear is required to ensure the toughness, while the tooth surface can meet the requirements of hardness, to meet the strength requirements of the use. Under the condition of certain gear manufacturing technology, the hardness and wear resistance of gear surface can be improved rapidly and effectively by laser surface quenching technology.

Laser surface quenching technology, also known as laser phase change hardening, USES a high energy laser as a heat source to make the metal surface hot and cold quickly, instantly complete the quenching process, get high hardness, ultra-fine martensite structure, improve the metal surface hardness and wear resistance, and form compressive stress on the surface, improve the fatigue strength.

Laser surface quenching features:

1 selection quenching, laser quenching can be used to quench the specified area of complex parts, which is very suitable for tooth surface strengthening;

2. Fine grain, extremely fine martensite grain, high dislocation density, and significantly improved surface wear resistance.

3. Small deformation, laser quenching extremely hot and fast cooling, quenching process in a very short time, small heat affected area, quenching stress and deformation, suitable for different shapes and sizes of gears.

4. Energy saving and environmental protection: The laser system with high conversion efficiency is adopted without water/oil and other cooling media.

Gear laser quenching applications

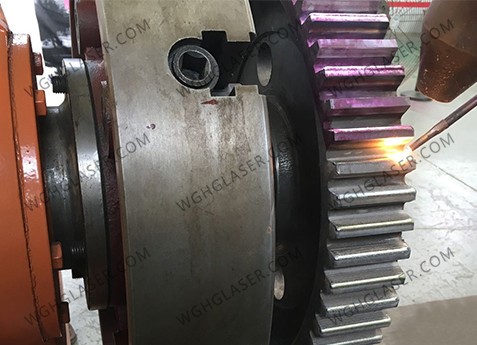

Laser quenching of outer tooth ring

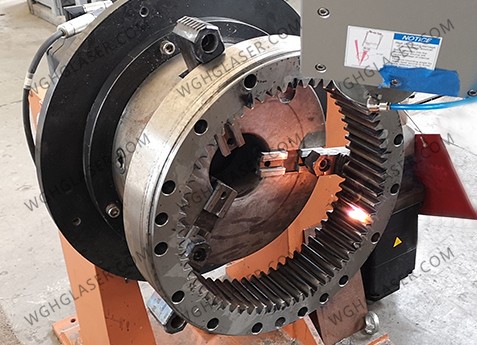

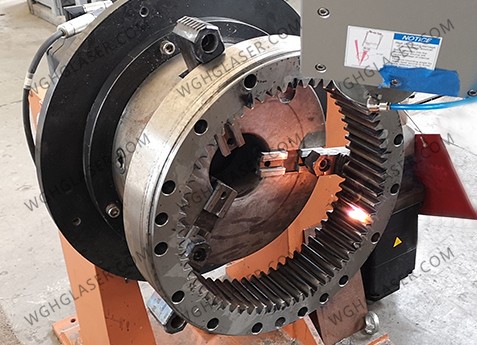

Laser quenching of inner tooth ring

Radar gear ring laser quenching

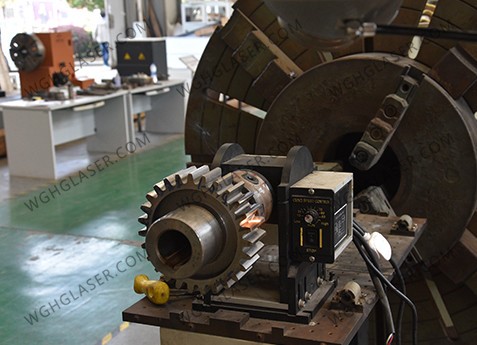

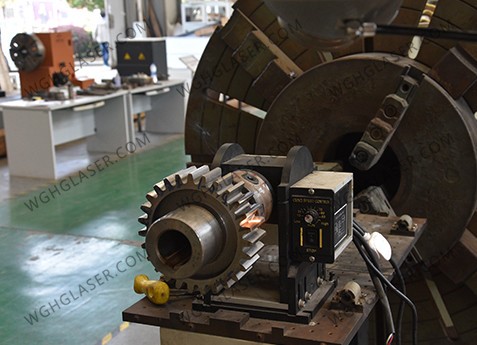

Pinion laser quenching

By means of laser quenching, the service life of gear can be extended exponentially, the cycle of gear replacement can be reduced, and the production cost of the enterprise can be effectively saved.

Laser surface cladding

The gear's occlusal surface requirement is high, the work labor intensity is large, so in the tooth surface occlusal area will appear first wear and flake, resulting in the failure of the gear scrap. The scrapping of large mechanical gears is an expensive expense. By laser surface cladding technology, the gear can be repaired and its use can be restored.

Laser surface cladding technology to repair, also called laser material manufacture, USES the high energy laser as a heat source, metal alloy powder as a welding material, through laser synchronization with alloy powder on the metal surface, the formation of dense, uniform and controllable metallurgical bonding layer thickness, so as to achieve and to strengthen the life extension repair of workpiece surface size effect.

Features of laser cladding repair:

1. The thickness of cladding layer is optional, and the original size of the gear can be restored as required;

2. Wear resistance and corrosion resistance, the cladding layer has anti-erosion, anti-wear and anti-corrosion properties;

3. Good metallurgical combination. The cladding layer and the matrix are combined with dense metallurgy, and will not flake off under heavy load and impact service conditions;

4. Low dilution, short laser action time, low cladding layer dilution (5%~8%), saving expensive cladding material;

5. High quality, no thick casting structure, fine solidification structure, compact interface structure, fine grain, no holes, no inclusion cracks and other defects.

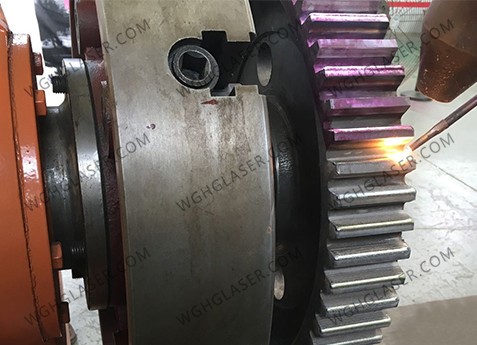

Application of laser surface cladding for gear

By laser surface cladding repair, the gear can be restored to its original size, so that the failed gear can be used again. Moreover, the wear resistance and corrosion resistance of the gear surface repaired by laser cladding are also improved. Effectively extend the service life of the gear.

Laser surface treatment technology are widely used in machinery industry, not only to strengthen the repair, the gear can also for axial and rolling mill, hydraulic support, such as inner hole for laser surface cladding repairing, for mould, crankshaft, cylinder and so on laser surface quenching strengthening, rust, paint, oxidation layer of conventional laser surface cleaning, etc.

Quality casts the brand, professional achievement is efficient! Wisco Laser has a professional team, rich experience, warm service, good reputation. No matter you need laser cladding, laser quenching, laser cleaning equipment, or laser surface treatment and processing business, you can contact us, WisCO Huazong laser quality, service casting reputation, sharing win-win, for the science and technology closer to life, for the manufacture of higher glory.

I. Laser surface quenching

Gears are widely used in all walks of life. Due to the working characteristics of the gear, the central part of the gear is required to ensure the toughness, while the tooth surface can meet the requirements of hardness, to meet the strength requirements of the use. Under the condition of certain gear manufacturing technology, the hardness and wear resistance of gear surface can be improved rapidly and effectively by laser surface quenching technology.

Laser surface quenching technology, also known as laser phase change hardening, USES a high energy laser as a heat source to make the metal surface hot and cold quickly, instantly complete the quenching process, get high hardness, ultra-fine martensite structure, improve the metal surface hardness and wear resistance, and form compressive stress on the surface, improve the fatigue strength.

Laser surface quenching features:

1 selection quenching, laser quenching can be used to quench the specified area of complex parts, which is very suitable for tooth surface strengthening;

2. Fine grain, extremely fine martensite grain, high dislocation density, and significantly improved surface wear resistance.

3. Small deformation, laser quenching extremely hot and fast cooling, quenching process in a very short time, small heat affected area, quenching stress and deformation, suitable for different shapes and sizes of gears.

4. Energy saving and environmental protection: The laser system with high conversion efficiency is adopted without water/oil and other cooling media.

Gear laser quenching applications

Laser quenching of outer tooth ring

Laser quenching of inner tooth ring

Radar gear ring laser quenching

Pinion laser quenching

By means of laser quenching, the service life of gear can be extended exponentially, the cycle of gear replacement can be reduced, and the production cost of the enterprise can be effectively saved.

Laser surface cladding

The gear's occlusal surface requirement is high, the work labor intensity is large, so in the tooth surface occlusal area will appear first wear and flake, resulting in the failure of the gear scrap. The scrapping of large mechanical gears is an expensive expense. By laser surface cladding technology, the gear can be repaired and its use can be restored.

Laser surface cladding technology to repair, also called laser material manufacture, USES the high energy laser as a heat source, metal alloy powder as a welding material, through laser synchronization with alloy powder on the metal surface, the formation of dense, uniform and controllable metallurgical bonding layer thickness, so as to achieve and to strengthen the life extension repair of workpiece surface size effect.

Features of laser cladding repair:

1. The thickness of cladding layer is optional, and the original size of the gear can be restored as required;

2. Wear resistance and corrosion resistance, the cladding layer has anti-erosion, anti-wear and anti-corrosion properties;

3. Good metallurgical combination. The cladding layer and the matrix are combined with dense metallurgy, and will not flake off under heavy load and impact service conditions;

4. Low dilution, short laser action time, low cladding layer dilution (5%~8%), saving expensive cladding material;

5. High quality, no thick casting structure, fine solidification structure, compact interface structure, fine grain, no holes, no inclusion cracks and other defects.

Application of laser surface cladding for gear

By laser surface cladding repair, the gear can be restored to its original size, so that the failed gear can be used again. Moreover, the wear resistance and corrosion resistance of the gear surface repaired by laser cladding are also improved. Effectively extend the service life of the gear.

Laser surface treatment technology are widely used in machinery industry, not only to strengthen the repair, the gear can also for axial and rolling mill, hydraulic support, such as inner hole for laser surface cladding repairing, for mould, crankshaft, cylinder and so on laser surface quenching strengthening, rust, paint, oxidation layer of conventional laser surface cleaning, etc.

Quality casts the brand, professional achievement is efficient! Wisco Laser has a professional team, rich experience, warm service, good reputation. No matter you need laser cladding, laser quenching, laser cleaning equipment, or laser surface treatment and processing business, you can contact us, WisCO Huazong laser quality, service casting reputation, sharing win-win, for the science and technology closer to life, for the manufacture of higher glory.