Laser surface quenching - Let the heat treatment of metal surfaces to be control

Metal heat treatment is one of the important processes in mechanical manufacturing, which can be divided into three categories: integral heat treatment, surface heat treatment and chemical heat treatment. Compared with other processing processes, heat treatment generally does not change the shape of the workpiece and the overall chemical composition, but by changing the internal microstructure of the workpiece, or changing the chemical composition of the surface of the workpiece, to give or improve the performance of the workpiece.

Laser surface quenching using high energy laser as a heat source, made the metal surface fast hot or fast cold, instantly complete the quenching process, without oil and water and other cooling media, get high hardness, ultrafine martensite structure, improve the hardness and wear resistance of the metal surface, and the formation of compressive stress on the surface, improve fatigue strength.

Compared with other surface heat treatment technologies (such as high-frequency quenching, carburizing, nitriding and other traditional processes), laser surface quenching has special advantages:

1) The quenching process is controllable: it can be imported into the quenching track by digital model, and the quenching temperature and quality can be precisely controlled by closed-loop method. Laser quenching can be carried out on large surface complex curved workpiece, such as mold, shaft, workpiece inner hole, etc.

2) local selection processing: precise control of hardening layer position, area, hardness, strengthening layer strength uniformity is good.

3) surface performance excellent : quenching martensite grain is very fine, high dislocation density, surface wear resistance and adhesion resistance can be greatly improved.

4) Small heat affected zone: laser surface quenching is extremely hot and quickly cold, the quenching process is completed in a very short time, and the quenching stress and deformation are small.

5) high hardness: hardening layer hardness is higher than the traditional quenching, wear resistance is doubled.

Hardness of guide rail after laser quenching

Application field

Because of its excellent heat treatment performance, laser surface quenching is widely used in mold, machinery manufacturing, petroleum, chemical industry, light industry, hardware tools, auto parts and other fields. Among them, metal alloy is the most widely used materials in industry, the microstructure is complex, can be controlled by laser heat treatment, change its mechanical, physical and chemical properties, in order to obtain different performance. Typical workpiece: mold, gear, shaft, thread, guide rail, cylinder liner, important military products, etc.

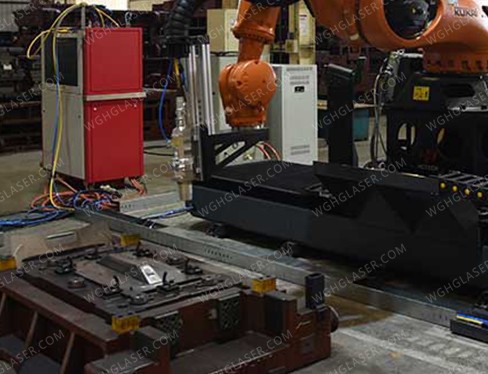

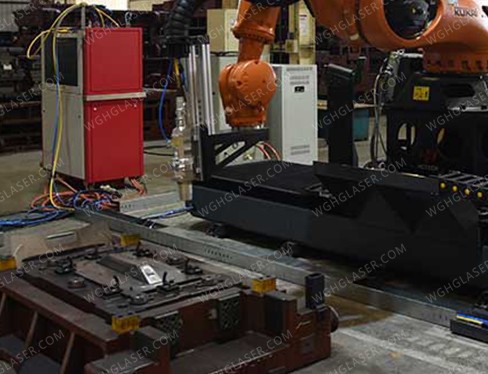

Die laser quenching

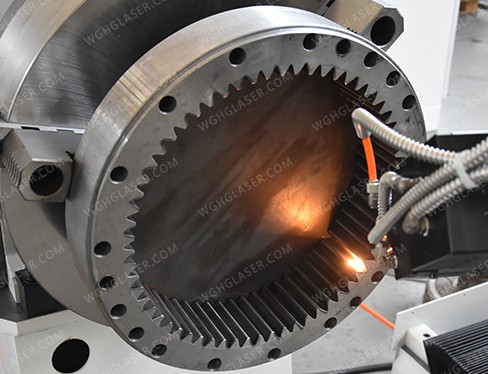

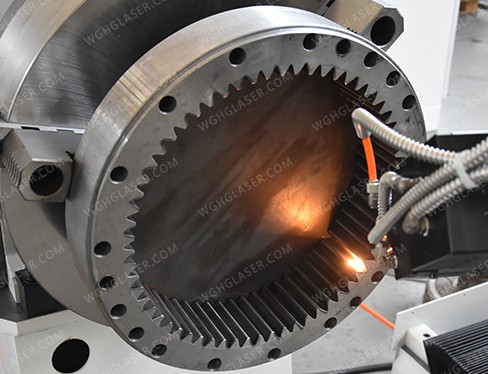

Laser quenching of gear ring

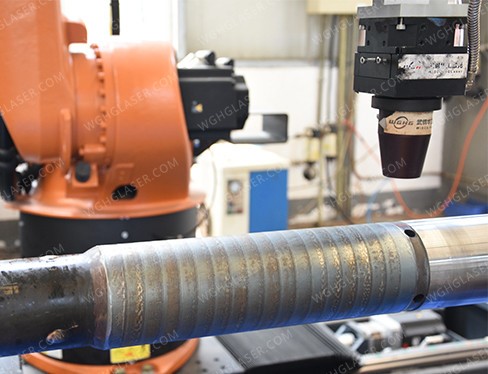

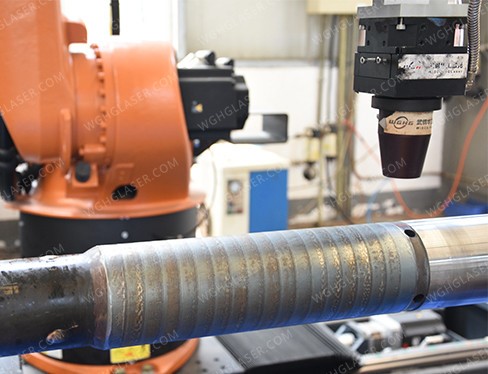

Axial laser hardening

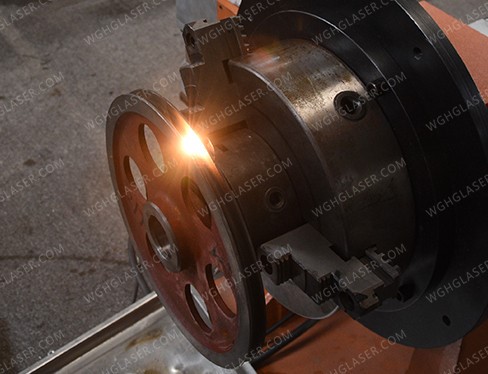

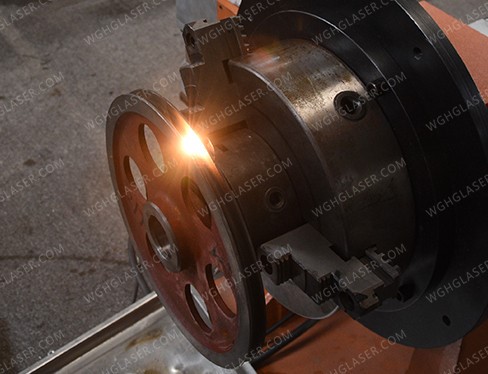

Thread laser quenching

Laser quenching of cylinder liner

Lift wheel laser quenching

Quality creates brand, professional achieves high quality! WG-HG Laser have a professional team, rich experience, warm service and good prestige. Whether you need aser surface hardening equipment or laser surface hardening business, HG-HG laser share total win.PLS contact us for more detailed information.

Laser surface quenching using high energy laser as a heat source, made the metal surface fast hot or fast cold, instantly complete the quenching process, without oil and water and other cooling media, get high hardness, ultrafine martensite structure, improve the hardness and wear resistance of the metal surface, and the formation of compressive stress on the surface, improve fatigue strength.

Compared with other surface heat treatment technologies (such as high-frequency quenching, carburizing, nitriding and other traditional processes), laser surface quenching has special advantages:

1) The quenching process is controllable: it can be imported into the quenching track by digital model, and the quenching temperature and quality can be precisely controlled by closed-loop method. Laser quenching can be carried out on large surface complex curved workpiece, such as mold, shaft, workpiece inner hole, etc.

2) local selection processing: precise control of hardening layer position, area, hardness, strengthening layer strength uniformity is good.

3) surface performance excellent : quenching martensite grain is very fine, high dislocation density, surface wear resistance and adhesion resistance can be greatly improved.

4) Small heat affected zone: laser surface quenching is extremely hot and quickly cold, the quenching process is completed in a very short time, and the quenching stress and deformation are small.

5) high hardness: hardening layer hardness is higher than the traditional quenching, wear resistance is doubled.

Hardness of guide rail after laser quenching

Application field

Because of its excellent heat treatment performance, laser surface quenching is widely used in mold, machinery manufacturing, petroleum, chemical industry, light industry, hardware tools, auto parts and other fields. Among them, metal alloy is the most widely used materials in industry, the microstructure is complex, can be controlled by laser heat treatment, change its mechanical, physical and chemical properties, in order to obtain different performance. Typical workpiece: mold, gear, shaft, thread, guide rail, cylinder liner, important military products, etc.

Die laser quenching

Laser quenching of gear ring

Axial laser hardening

Thread laser quenching

Laser quenching of cylinder liner

Lift wheel laser quenching

Quality creates brand, professional achieves high quality! WG-HG Laser have a professional team, rich experience, warm service and good prestige. Whether you need aser surface hardening equipment or laser surface hardening business, HG-HG laser share total win.PLS contact us for more detailed information.