Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

Laser Cleaning

High energy laser beam is used to irradiate the surface of workpiece, which makes the dirt, rust spots, particles or coating evaporate or expand and peel instantly, so as to achieve the process of cleaning and purification.

Customer benefits:

Precise machining/No damage to the substrate/Low cost of use/Protect environment

Application area:

It is applied to the laser cleaning processes such as laser rust removal, laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser de-coating, and so on on workpiece surface, and is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military, ship, oil, transportation and other fields.

Laser derusting for engine

Laser derusting for Train wheels

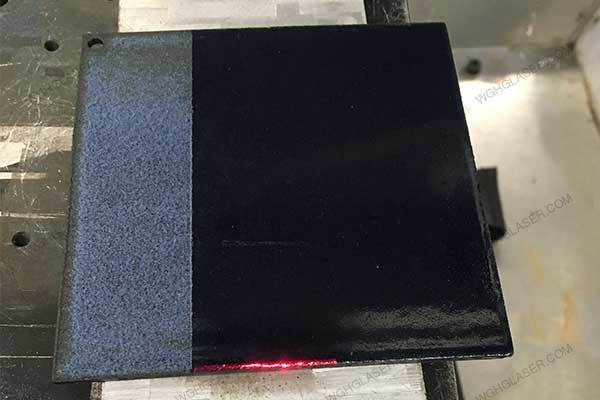

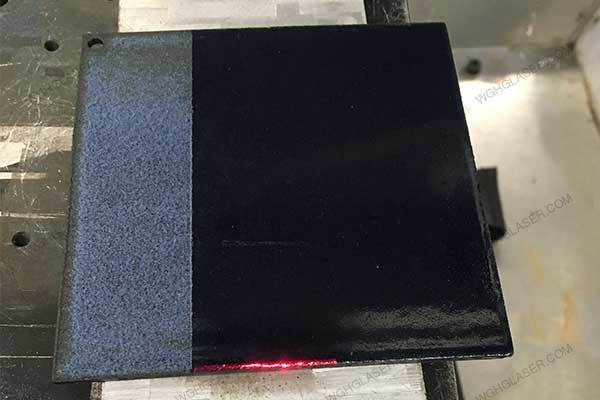

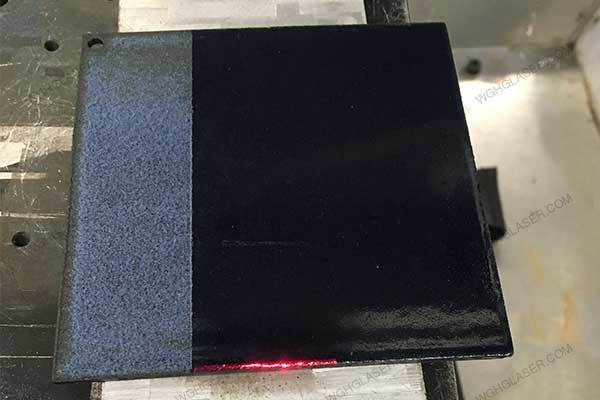

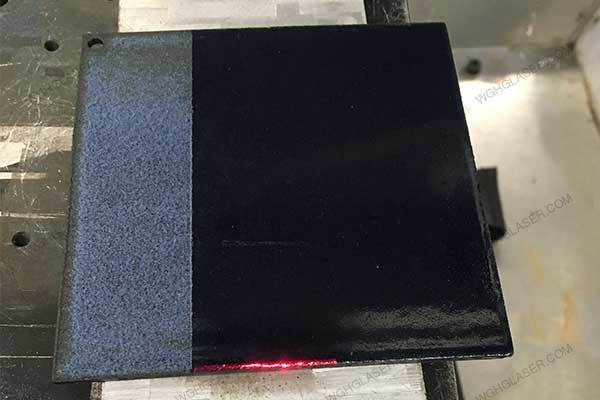

Laser derusting for mold

Laser cleaning for Tanks chain

Laser glue removal for mold

Laser glue removal for Copper wire

Laser paint removal for Aluminum plate

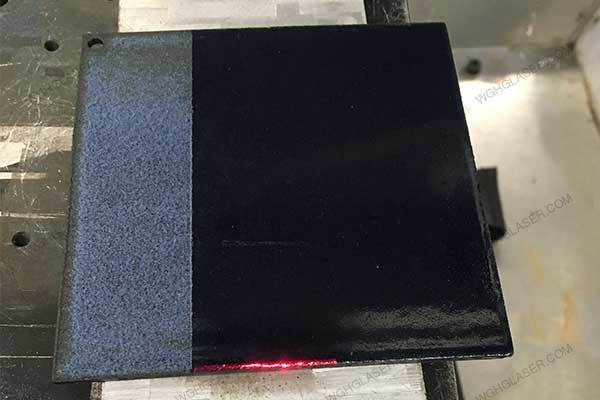

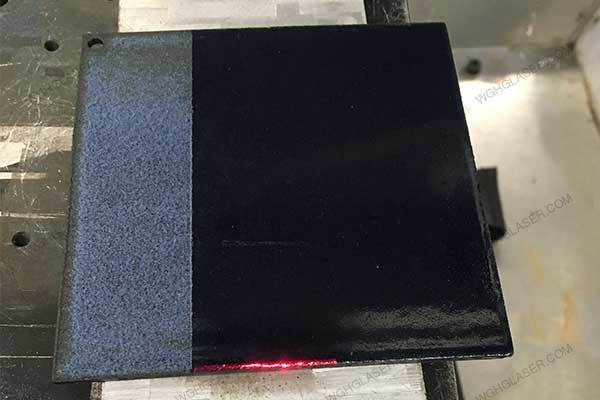

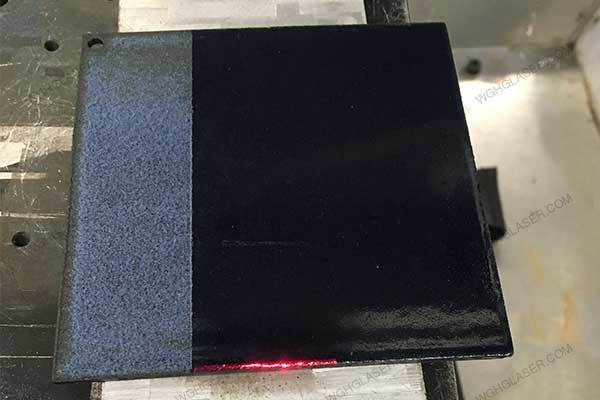

Laser removal of ceramics for Sheet metal

Related Products

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

Laser Cleaning

High energy laser beam is used to irradiate the surface of workpiece, which makes the dirt, rust spots, particles or coating evaporate or expand and peel instantly, so as to achieve the process of cleaning and purification.

Customer benefits:

Precise machining/No damage to the substrate/Low cost of use/Protect environment

Application area:

It is applied to the laser cleaning processes such as laser rust removal, laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser de-coating, and so on on workpiece surface, and is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military, ship, oil, transportation and other fields.

Laser derusting for engine

Laser derusting for Train wheels

Laser derusting for mold

Laser cleaning for Tanks chain

Laser glue removal for mold

Laser glue removal for Copper wire

Laser paint removal for Aluminum plate

Laser removal of ceramics for Sheet metal

Related Products

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

Laser Cleaning

High energy laser beam is used to irradiate the surface of workpiece, which makes the dirt, rust spots, particles or coating evaporate or expand and peel instantly, so as to achieve the process of cleaning and purification.

Customer benefits:

Precise machining/No damage to the substrate/Low cost of use/Protect environment

Application area:

It is applied to the laser cleaning processes such as laser rust removal, laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser de-coating, and so on on workpiece surface, and is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military, ship, oil, transportation and other fields.

Laser derusting for engine

Laser derusting for Train wheels

Laser derusting for mold

Laser cleaning for Tanks chain

Laser glue removal for mold

Laser glue removal for Copper wire

Laser paint removal for Aluminum plate

Laser removal of ceramics for Sheet metal

Related Products

Laser Cleaning Equipment Series

Laser Cleaning

High energy laser beam is used to irradiate the surface of workpiece, which makes the dirt, rust spots, particles or coating evaporate or expand and peel instantly, so as to achieve the process of cleaning and purification.

Customer benefits:

Precise machining/No damage to the substrate/Low cost of use/Protect environment

Application area:

It is applied to the laser cleaning processes such as laser rust removal, laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser de-coating, and so on on workpiece surface, and is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military, ship, oil, transportation and other fields.

Laser derusting for engine

Laser derusting for Train wheels

Laser derusting for mold

Laser cleaning for Tanks chain

Laser glue removal for mold

Laser glue removal for Copper wire

Laser paint removal for Aluminum plate

Laser removal of ceramics for Sheet metal

Related Products

Laser Cleaning

High energy laser beam is used to irradiate the surface of workpiece, which makes the dirt, rust spots, particles or coating evaporate or expand and peel instantly, so as to achieve the process of cleaning and purification.

Customer benefits:

Precise machining/No damage to the substrate/Low cost of use/Protect environment

Application area:

It is applied to the laser cleaning processes such as laser rust removal, laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser de-coating, and so on on workpiece surface, and is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military, ship, oil, transportation and other fields.

Laser derusting for engine

Laser derusting for Train wheels

Laser derusting for mold

Laser cleaning for Tanks chain

Laser glue removal for mold

Laser glue removal for Copper wire

Laser paint removal for Aluminum plate

Laser removal of ceramics for Sheet metal

Related Products

Laser Cleaning

Brief introduction:

High energy laser beam is used to irradiate the surface of workpiece, which makes the dirt, rust spots, particles or coating evaporate or expand and peel instantly, so as to achieve the process of cleaning and purification.

Customer benefits:

Precise machining/No damage to the substrate/Low cost of use/Protect environment

Application area:

It is applied to the laser cleaning processes such as laser rust removal, laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser de-coating, and so on on workpiece surface, and is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military, ship, oil, transportation and other fields.

High energy laser beam is used to irradiate the surface of workpiece, which makes the dirt, rust spots, particles or coating evaporate or expand and peel instantly, so as to achieve the process of cleaning and purification.

Customer benefits:

Precise machining/No damage to the substrate/Low cost of use/Protect environment

Application area:

It is applied to the laser cleaning processes such as laser rust removal, laser degreasing, laser paint removal, laser zinc removal, laser film removal, laser de-coating, and so on on workpiece surface, and is widely used in aerospace, mold, microelectronics, construction, nuclear power plants, automobile manufacturing, medical, cultural relics protection, military, ship, oil, transportation and other fields.

Laser derusting for engine

Laser derusting for Train wheels

Laser derusting for mold

Laser cleaning for Tanks chain

Laser glue removal for mold

Laser glue removal for Copper wire

Laser paint removal for Aluminum plate