laser cladding technology characteristics and industry application

Laser cladding,, uses a high energy laser as a heat source, metal alloy powder as welding material, through the laser and alloy powder (or wire material) synchronous action on the metal surface to quickly melt to form a molten pool, and then rapid solidification to form a dense, uniform and thickness controllable metallurgical bonding layer.

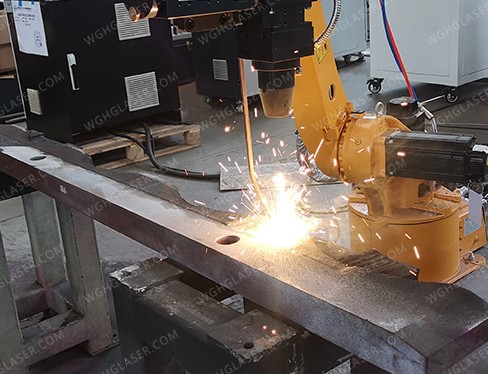

Roller High speed laser cladding

Compared with many traditional surface treatment technologies, laser cladding technology has the following significant advantages and characteristics:

1) High metallurgical bonding strength. Laser cladding makes use of the characteristics of high energy laser beam to gather high energy, which makes the workpiece surface melt instantly, and at the same time makes the alloy powder preset on the workpiece surface or automatically sent with laser beam melt completely. After scanning by laser beam, the matrix solidifies rapidly by self-cooling, so that the alloy layer of dense overlay combined with matrix metallurgy can be obtained.

2) Hardness and thickness are optional. After laser cladding, the hardness of the cladding layer can be selected from HRC20-62, and the cladding thickness can be adjusted according to the need.

3) wear and corrosion resistance. Laser cladding can be applied on the surface of common carbon steel workpiece, which is corrosion-resistant, wear-resistant and has excellent performance.

4) Reduce costs and energy consumption. By forming metallurgical bonding alloy coating on the surface of the substrate with different alloy composition and properties, laser cladding can produce high-performance alloy functional layer on the substrate with low cost and save material cost.

5) High cladding quality. Small deformation, good mechanical repeatability, compact interface structure, fine grain, no holes, no cracks and other defects.

Application of laser cladding

After decades of development, laser cladding technology has been widely used in metallurgical industry, coal industry, petrochemical industry, transportation, machinery manufacturing, mold industry, hardware tools and other industries from the laboratory into the actual industrial application.

1. Metallurgical industry

According to a preliminary estimate, the annual consumption of important parts and components in the steel rolling production lines in China amounts to 10 billion yuan. The traditional method is mainly to replace the parts of these equipment, or even because the parts can not be used to scrap or replace the whole machine, damage and failure and scrap parts or the whole machine is basically treated as waste, resulting in a large amount of waste of resources. Laser cladding can repair the equipment on the parts of metal base material preparation of high-performance alloy surface, can significantly improve the surface wear resistance, corrosion resistance, heat resistance, oxidation resistance and electric performance, not only can prolong the service life of the new parts, also can have wear parts for cladding repair, restore its original size, thereby reducing the cycle of replacement parts.

Laser cladding repair of side guide plate

Laser cladding repair of flat head sleeve

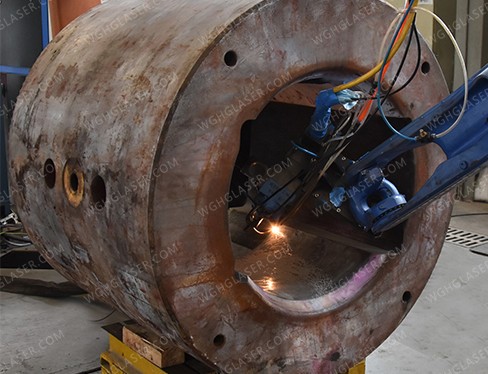

2. Coal machine industry

The characteristics of mining machinery and equipment: large volume, high price, difficult loading and unloading, and large maintenance workload. Therefore, when the parts stop running due to wear and tear, it will cause huge economic losses. Laser cladding can be used for surface remanufacturing of new and old parts, such as hydraulic cylinder, column laser cladding, so as to effectively improve the wear resistance and corrosion resistance of parts, prolong the service life of parts.

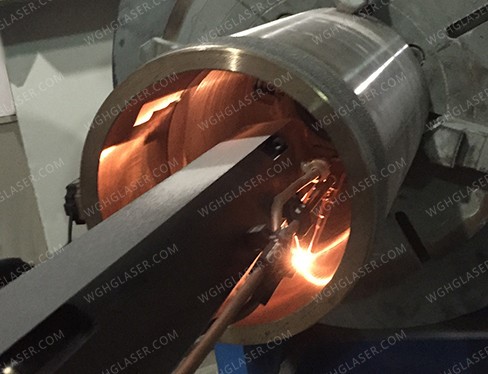

Hydraulic cylinder inner hole laser cladding

Laser high speed cladding for hydraulic cylinder

High thickness laser cladding for hydraulic cylinders

WISC laser high-speed laser cladding, not only faster than the traditional laser cladding processing speed, the surface is more smooth and smooth, and the processed parts, only need to finish processing can be put into production and use, save a lot of machining time and cost, will be a major technical force of laser surface remanufacturing in the future.

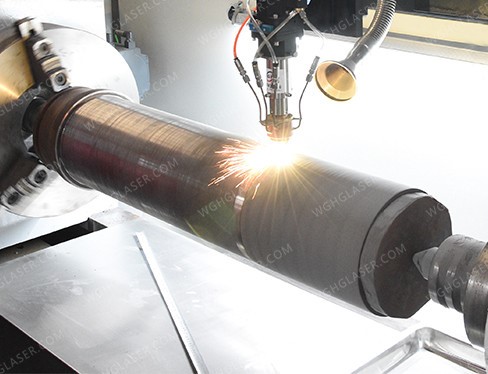

3. Petrochemical industry

In the petrochemical industry, it is particularly important to maintain the equipment parts regularly because the equipment works in the harsh environment for a long time, which is easy to make the products corroded and worn. Laser cladding can repair the failed parts by cladding, restore the original size, and effectively restore the use of equipment.

Laser cladding of drilling rods

Laser cladding of drilling tool components

4. Transportation industry

The transportation industry includes land, water and air transportation, etc. The characteristics of transportation equipment are high frequency of use and complex and changeable environment, leading to the need for regular maintenance of equipment. Laser cladding can repair all kinds of parts to restore their original size, so as to effectively improve the service cycle of parts.

Laser cladding of valve core

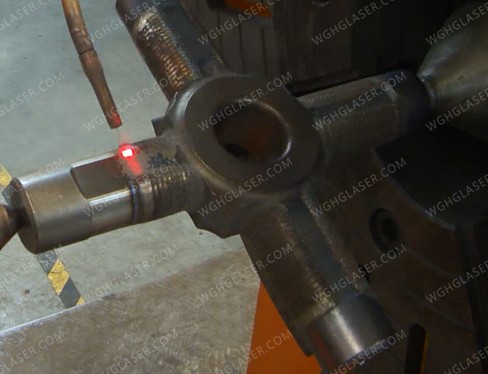

Cross shaft laser cladding repair

Laser cladding solves the problems such as the limitation of material selection, the thermal stress, the thermal deformation in the process, the coarse grain size of the material, and the difficulty in guaranteeing the bonding strength with the matrix, which cannot be solved by the traditional repair method. It can even produce a metal surface superior to the substrate, which can effectively extend the service life of parts while restoring the use of parts, and greatly reduce the production cost of enterprises.

Quality creates brand, professional achieves high quality! WG-HG Laser have a professional team, rich experience, warm service and good prestige. Whether you need cladding equipment or a laser cladding repair/remanufacturing process business,, HG-HG laser share total win.PLS contact us for more detailed information.

Laser Cladding Machine | laser cladding technology characteristics and industry application