Categories

Laser Cladding Equipment Series

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

Laser 3D printing

With laser coaxial powder feeding and cladding technology, metal powder melts and solidifies rapidly with the movement of laser processing head, forming various complex parts directly.

Customer benefits:

1. Convenient processing: directly make metal products and print large pieces

2. High processing efficiency: large light spot and high efficiency

3. High reliability: good structure and performance of formed parts, and high bonding strength

4. Processing and environmental protection: precision manufacturing, energy conservation and environmental protection

Application area:

At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, home appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields. Typical workpieces include various kinds of special-shaped pieces.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing for logo

Metal laser 3D printing

Metal laser 3D printing.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing

Related Products

Laser Quenching Equipment Series

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

Laser 3D printing

With laser coaxial powder feeding and cladding technology, metal powder melts and solidifies rapidly with the movement of laser processing head, forming various complex parts directly.

Customer benefits:

1. Convenient processing: directly make metal products and print large pieces

2. High processing efficiency: large light spot and high efficiency

3. High reliability: good structure and performance of formed parts, and high bonding strength

4. Processing and environmental protection: precision manufacturing, energy conservation and environmental protection

Application area:

At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, home appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields. Typical workpieces include various kinds of special-shaped pieces.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing for logo

Metal laser 3D printing

Metal laser 3D printing.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing

Related Products

Laser Texturing Equipment Series

Laser Cleaning Equipment Series

Laser 3D printing

With laser coaxial powder feeding and cladding technology, metal powder melts and solidifies rapidly with the movement of laser processing head, forming various complex parts directly.

Customer benefits:

1. Convenient processing: directly make metal products and print large pieces

2. High processing efficiency: large light spot and high efficiency

3. High reliability: good structure and performance of formed parts, and high bonding strength

4. Processing and environmental protection: precision manufacturing, energy conservation and environmental protection

Application area:

At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, home appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields. Typical workpieces include various kinds of special-shaped pieces.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing for logo

Metal laser 3D printing

Metal laser 3D printing.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing

Related Products

Laser Cleaning Equipment Series

Laser 3D printing

With laser coaxial powder feeding and cladding technology, metal powder melts and solidifies rapidly with the movement of laser processing head, forming various complex parts directly.

Customer benefits:

1. Convenient processing: directly make metal products and print large pieces

2. High processing efficiency: large light spot and high efficiency

3. High reliability: good structure and performance of formed parts, and high bonding strength

4. Processing and environmental protection: precision manufacturing, energy conservation and environmental protection

Application area:

At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, home appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields. Typical workpieces include various kinds of special-shaped pieces.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing for logo

Metal laser 3D printing

Metal laser 3D printing.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing

Related Products

Laser 3D printing

With laser coaxial powder feeding and cladding technology, metal powder melts and solidifies rapidly with the movement of laser processing head, forming various complex parts directly.

Customer benefits:

1. Convenient processing: directly make metal products and print large pieces

2. High processing efficiency: large light spot and high efficiency

3. High reliability: good structure and performance of formed parts, and high bonding strength

4. Processing and environmental protection: precision manufacturing, energy conservation and environmental protection

Application area:

At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, home appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields. Typical workpieces include various kinds of special-shaped pieces.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing for logo

Metal laser 3D printing

Metal laser 3D printing.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing

Related Products

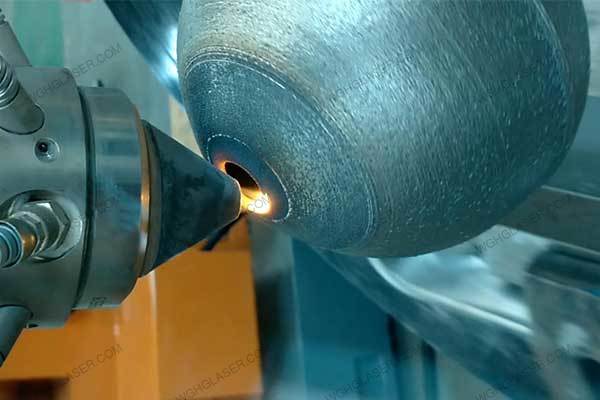

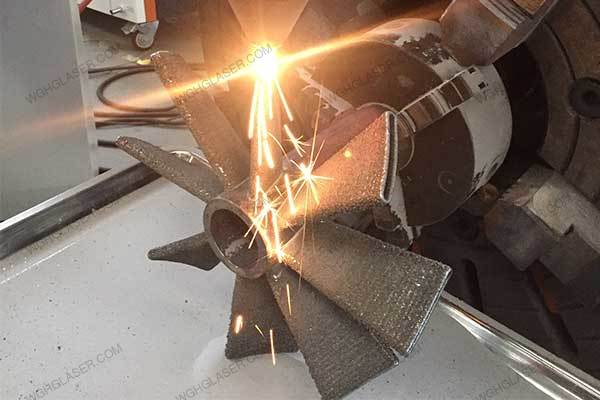

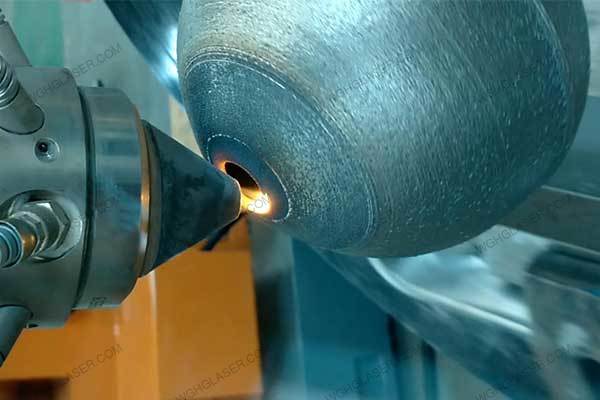

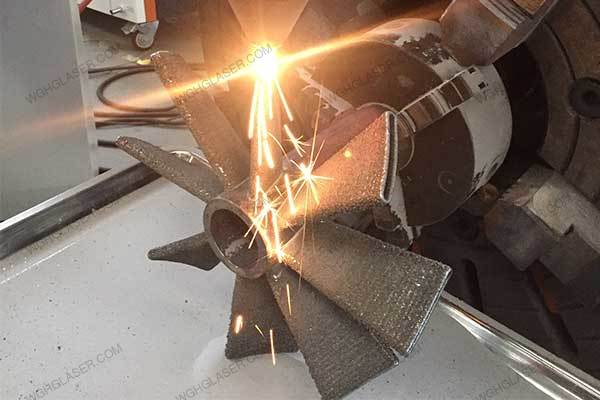

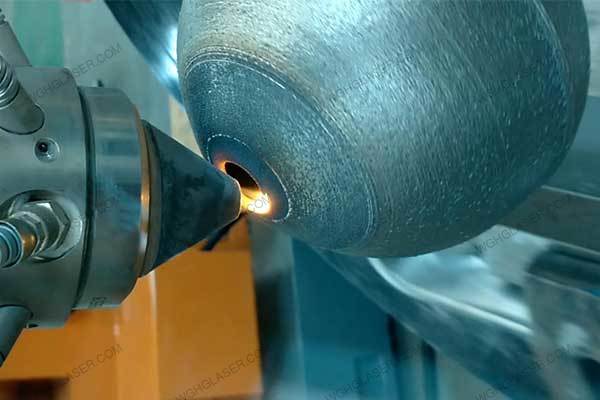

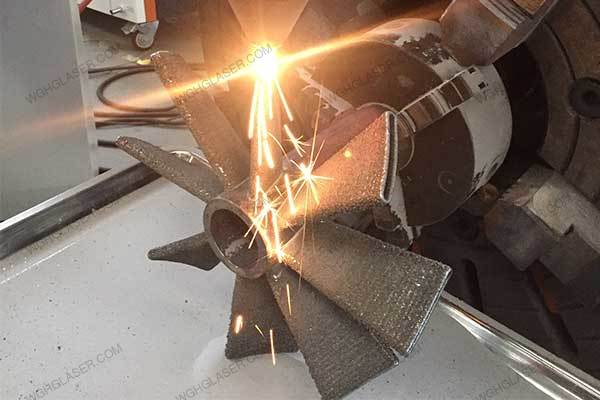

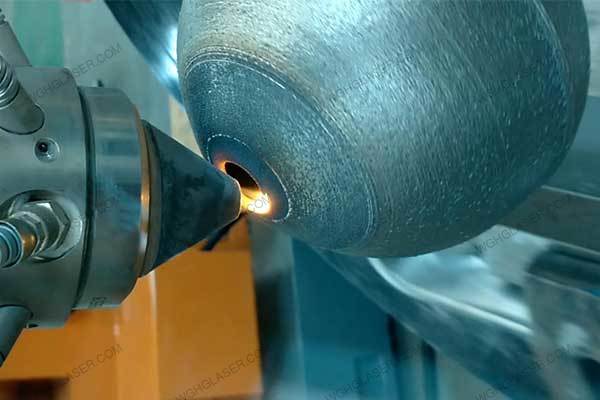

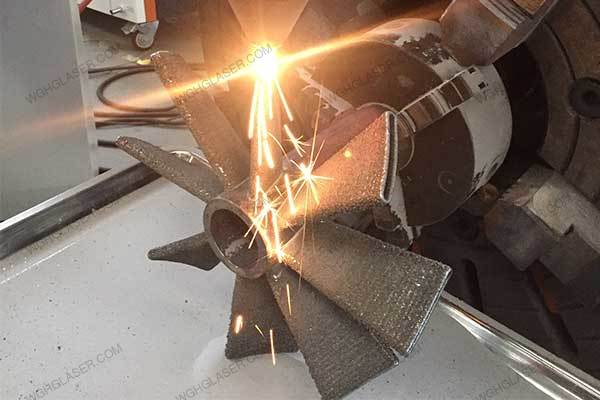

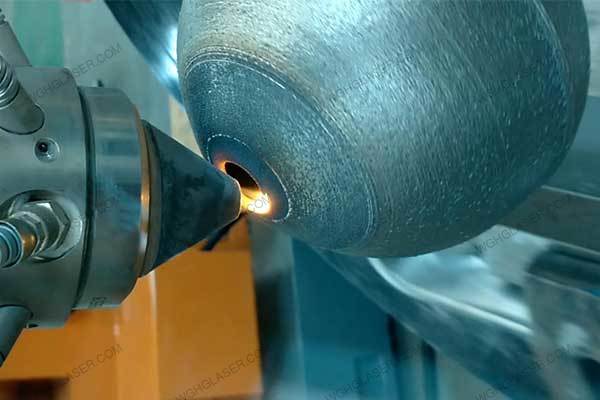

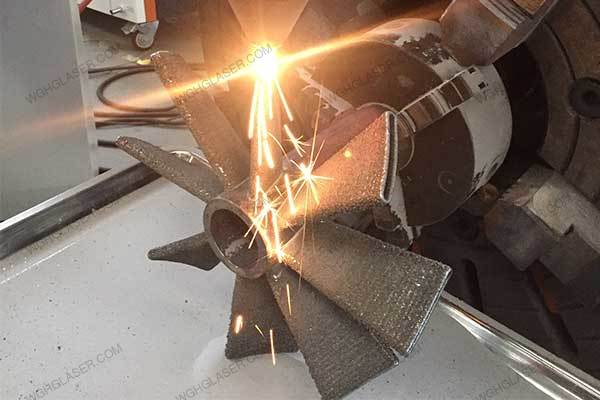

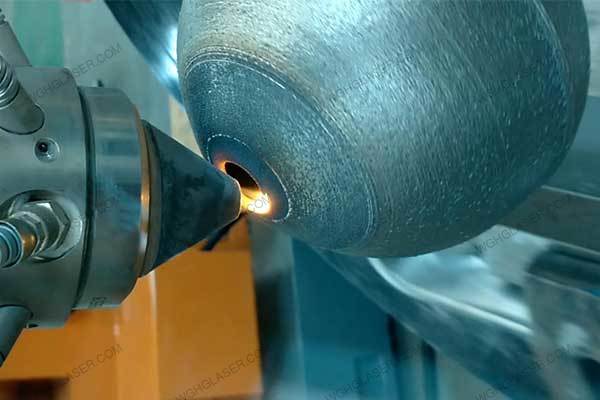

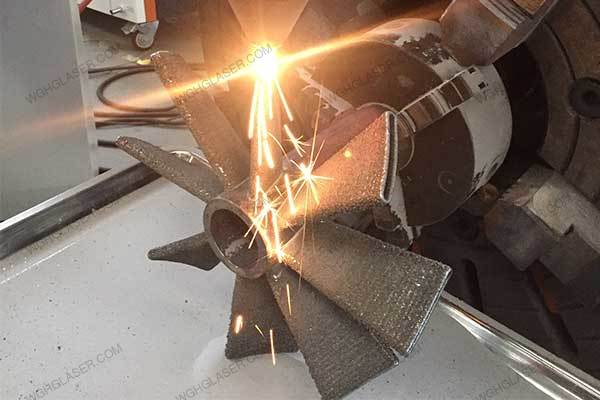

Laser 3D printing

Brief introduction:

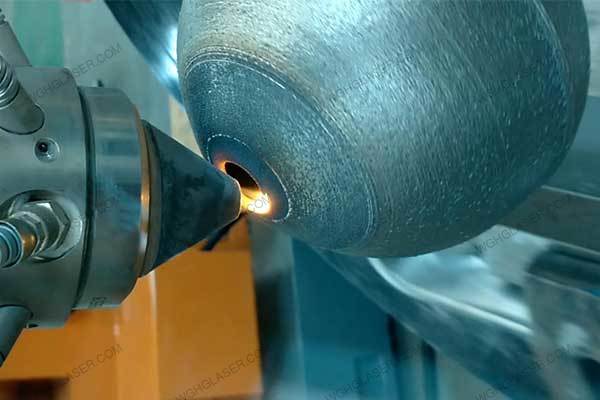

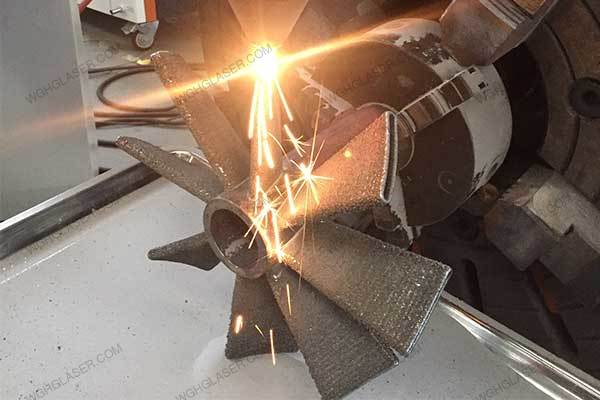

With laser coaxial powder feeding and cladding technology, metal powder melts and solidifies rapidly with the movement of laser processing head, forming various complex parts directly.

Customer benefits:

1. Convenient processing: directly make metal products and print large pieces

2. High processing efficiency: large light spot and high efficiency

3. High reliability: good structure and performance of formed parts, and high bonding strength

4. Processing and environmental protection: precision manufacturing, energy conservation and environmental protection

Application area:

At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, home appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields. Typical workpieces include various kinds of special-shaped pieces.

With laser coaxial powder feeding and cladding technology, metal powder melts and solidifies rapidly with the movement of laser processing head, forming various complex parts directly.

Customer benefits:

1. Convenient processing: directly make metal products and print large pieces

2. High processing efficiency: large light spot and high efficiency

3. High reliability: good structure and performance of formed parts, and high bonding strength

4. Processing and environmental protection: precision manufacturing, energy conservation and environmental protection

Application area:

At present, it has been widely used in industrial modeling, machinery manufacturing, aerospace, military, architecture, film and television, home appliances, light industry, medicine, archaeology, culture and art, sculpture, jewelry and other fields. Typical workpieces include various kinds of special-shaped pieces.

Metal laser 3D printing

Metal laser 3D printing

Metal laser 3D printing for logo

Metal laser 3D printing

Metal laser 3D printing.

Metal laser 3D printing

Metal laser 3D printing