Environmental the application of laser cleaning in metal welding

Welding technology is a manufacturing technology that combines metal or other thermoplastic materials by heating.Always commonly used material processing method in engineering.Can connect different workpieces stably and effectively. In order to prevent the weld from having pores, cracks, rough appearance, uneven organization and other defects, affecting the welding quality, Before welding.clean the dirt and rust on the surface of the welding joint is the most important.

During the welding process, heat treatment will lead to the oxidation at the interface,make oxide layer. cleaning of the oxide skin, slag skin and spatter,It s usefull and inspection of welding defects after welding, Easy to find detection of surface defects and elimination and repair, to ensure the surface quality of the product.

Now The existing methods of surface treatment after welding are mainly mechanical grinding and chemical cleaning. Mechanical grinding is easy to cause workpiece damage, difficult to deal with the complex surface processing, and noise pollution, high-intensity work. Chemical cleaning is not suitable for local cleaning, easy to cause environmental pollution.

The new laser cleaning technology is to use the high-energy laser beam to illuminate the surface of the workpiece, Make the surface of dirt, rust, particles or coating instantly evaporation or expansion of peeling, to achieve the process of cleaning.

Laser cleaning before plate welding

Features of laser cleaning technology

There are some problem from the process of the treatment of stainless steel welding seam, such as cracks, holes, solid impurities, not fusion, not welding penetration, shape defects, etc., the Conventional welding seam process treatment is complex, Not only to achieve, but also need to spend a lot of time, reduce the production efficiency. The application of laser cleaning machine on metal welding surface has the competitive advantage that traditional cleaning method does not have, which is mainly reflected in the following aspects:

1) Comprehensive functions: Laser cleaning not only remove rust, oil, oxide layer and other substances attached to the metal surface, but also remove dust, impurities and so on. It can efficiently treat stainless steel welds, including welding pretreatment, which is efficient and saves time and effort.

2) Local cleaning: The laser beam can not only adjust the size of the spot, but also carry out accurate cleaning on specific parts of the metal surface. Laser intensity can also be adjusted to the various adhesive strength of the adhesive to achieve thorough cleaning.

3) Flexible operation: Laser cleaning has no contact with the material surface, and can effectively clean the complex curved surface of parts and parts that cannot be reached by conventional cleaning.

4) Do not damage the base material: Laser cleaning can achieve selective removal of pollutants, improve cleanliness, and protect the base material.

5) Environmental protection: the impurities cleaned by laser can be directly recycled by means of dust extraction, no noise, waste solution and no secondary pollution.

Application case of weld cleaning (after welding)

Laser cleaning removes lubricant, black and non-ferrous metal impurities on the metal, so that welding and brazing joints of high quality, smooth and no pores, to obtain the best stability and quality of visible welds, suitable for steel and aluminum surface cleaning. As pretreatment before and after welding, it is widely used in automobile industry, precision tool production, shipbuilding and other industries.

Laser cleaning of plate welds

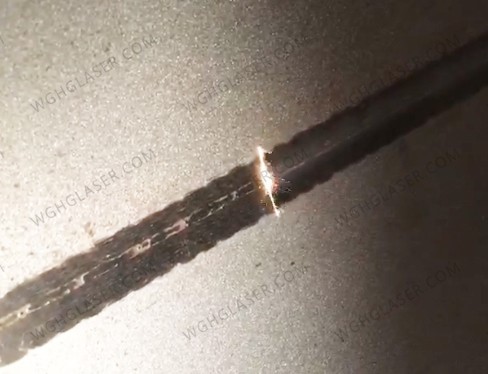

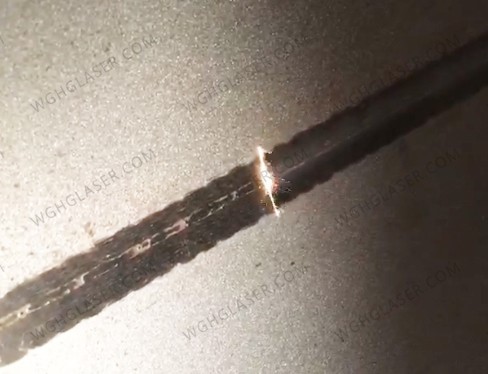

Laser cleaning of serrated welds

Laser cleaning can not only clean the small area of the workpiece, but also form the automatic production line of laser cleaning, cleaning and processing large quantities of the workpiece, thus improving the efficiency of laser cleaning.

Small workpieces weld cleaning flow line

WG-HG Laser has launched a series of laser cleaning products with different power, efficiency and structure, such as 10-60W backpack laser cleaning machine, low-power (50-200W) handheld laser cleaning machine, medium-power (200-500W) handheld laser cleaning machine, and high-power (500-1600W) laser cleaning machine.

Low and medium power cleaning machine, design with backpack, handheld or clamping design, flexible cleaning, can be used to clean specific parts of the base material, flexible operation.

Backpack laser cleaner

Handheld laser cleaner

High power laser cleaning machine adopts clamping design, cleaning efficiency is higher, very suitable for large volume and large area of the production environment of efficient equipment, more intelligent, efficient.

Clamping laser cleaning machine

The whole set of laser cleaning equipment adopts customized design, which can be used in a small range or form a laser cleaning flow line for aquatic products, so as to adapt to different places and meet the cleaning needs of different industries and working conditions. The long - term continuous operation of the laser ensures the stability and service life of the equipment.

Quality creates brand, professional achieves high quality! WG-HG Laser have a professional team, rich experience, warm service and good prestige. Whether you need laser cleaning equipment, or laser cleaning processing business, HG-HG laser share total win.PLS contact us for more detailed information.

During the welding process, heat treatment will lead to the oxidation at the interface,make oxide layer. cleaning of the oxide skin, slag skin and spatter,It s usefull and inspection of welding defects after welding, Easy to find detection of surface defects and elimination and repair, to ensure the surface quality of the product.

Now The existing methods of surface treatment after welding are mainly mechanical grinding and chemical cleaning. Mechanical grinding is easy to cause workpiece damage, difficult to deal with the complex surface processing, and noise pollution, high-intensity work. Chemical cleaning is not suitable for local cleaning, easy to cause environmental pollution.

The new laser cleaning technology is to use the high-energy laser beam to illuminate the surface of the workpiece, Make the surface of dirt, rust, particles or coating instantly evaporation or expansion of peeling, to achieve the process of cleaning.

Laser cleaning before plate welding

Features of laser cleaning technology

There are some problem from the process of the treatment of stainless steel welding seam, such as cracks, holes, solid impurities, not fusion, not welding penetration, shape defects, etc., the Conventional welding seam process treatment is complex, Not only to achieve, but also need to spend a lot of time, reduce the production efficiency. The application of laser cleaning machine on metal welding surface has the competitive advantage that traditional cleaning method does not have, which is mainly reflected in the following aspects:

1) Comprehensive functions: Laser cleaning not only remove rust, oil, oxide layer and other substances attached to the metal surface, but also remove dust, impurities and so on. It can efficiently treat stainless steel welds, including welding pretreatment, which is efficient and saves time and effort.

2) Local cleaning: The laser beam can not only adjust the size of the spot, but also carry out accurate cleaning on specific parts of the metal surface. Laser intensity can also be adjusted to the various adhesive strength of the adhesive to achieve thorough cleaning.

3) Flexible operation: Laser cleaning has no contact with the material surface, and can effectively clean the complex curved surface of parts and parts that cannot be reached by conventional cleaning.

4) Do not damage the base material: Laser cleaning can achieve selective removal of pollutants, improve cleanliness, and protect the base material.

5) Environmental protection: the impurities cleaned by laser can be directly recycled by means of dust extraction, no noise, waste solution and no secondary pollution.

Application case of weld cleaning (after welding)

Laser cleaning removes lubricant, black and non-ferrous metal impurities on the metal, so that welding and brazing joints of high quality, smooth and no pores, to obtain the best stability and quality of visible welds, suitable for steel and aluminum surface cleaning. As pretreatment before and after welding, it is widely used in automobile industry, precision tool production, shipbuilding and other industries.

Laser cleaning of plate welds

Laser cleaning of serrated welds

Laser cleaning can not only clean the small area of the workpiece, but also form the automatic production line of laser cleaning, cleaning and processing large quantities of the workpiece, thus improving the efficiency of laser cleaning.

Small workpieces weld cleaning flow line

WG-HG Laser has launched a series of laser cleaning products with different power, efficiency and structure, such as 10-60W backpack laser cleaning machine, low-power (50-200W) handheld laser cleaning machine, medium-power (200-500W) handheld laser cleaning machine, and high-power (500-1600W) laser cleaning machine.

Low and medium power cleaning machine, design with backpack, handheld or clamping design, flexible cleaning, can be used to clean specific parts of the base material, flexible operation.

Backpack laser cleaner

Handheld laser cleaner

High power laser cleaning machine adopts clamping design, cleaning efficiency is higher, very suitable for large volume and large area of the production environment of efficient equipment, more intelligent, efficient.

Clamping laser cleaning machine

The whole set of laser cleaning equipment adopts customized design, which can be used in a small range or form a laser cleaning flow line for aquatic products, so as to adapt to different places and meet the cleaning needs of different industries and working conditions. The long - term continuous operation of the laser ensures the stability and service life of the equipment.

Quality creates brand, professional achieves high quality! WG-HG Laser have a professional team, rich experience, warm service and good prestige. Whether you need laser cleaning equipment, or laser cleaning processing business, HG-HG laser share total win.PLS contact us for more detailed information.